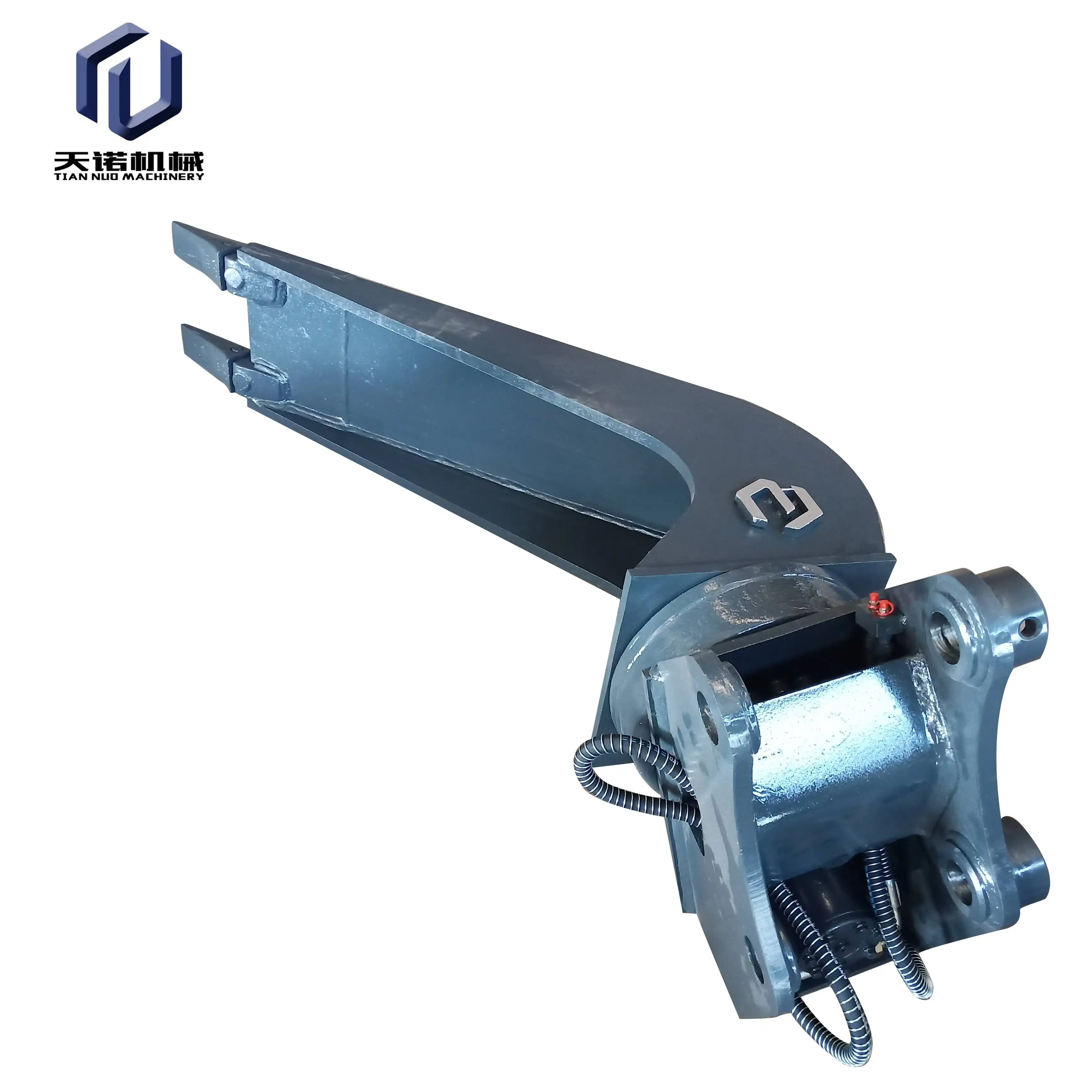

Excavator High Reach Demolition Long Boom And Arm For Tunnel Construction

Tunnel construction projects present unique challenges that require specialized equipment to ensure efficiency, safety, and precision. One such piece of equipment that has revolutionized tunnel construction is the excavator high reach demolition long boom and arm. This innovative attachment has become an indispensable tool for contractors working on tunnel projects, offering numerous benefits in terms of reach, versatility, and safety. In this comprehensive guide, we'll explore the advantages of using a high reach demolition long boom for tunnel construction and discuss best practices for its implementation.

Why is a high reach demolition long boom ideal for tunnel construction?

The excavator high reach demolition long boom and arm are particularly well-suited for tunnel construction due to its unique design and capabilities. Here are several reasons why this specialized equipment is ideal for tunnel projects:

1. Extended Reach: The primary advantage of a high reach demolition long boom is its ability to access areas that would be difficult or impossible to reach with standard excavator attachments. In tunnel construction, this extended reach allows operators to work on higher sections of the tunnel without the need for scaffolding or other temporary structures. This not only saves time but also reduces the risk associated with working at heights.

2. Precision and Control: High reach demolition booms are engineered to provide exceptional control and precision, even at extended heights. This level of accuracy is crucial in tunnel construction, where precise excavation and material removal are essential to maintain the structural integrity of the tunnel and ensure safety. The hydraulic systems and advanced controls of these booms allow operators to make minute adjustments, resulting in cleaner cuts and more efficient material removal.

3. Versatility: Excavator high reach demolition long booms and arms can be equipped with various attachments, making them highly versatile tools for tunnel construction. From hydraulic hammers for breaking through hard rock to specialized buckets for material removal, these booms can adapt to different stages of the tunneling process. This versatility reduces the need for multiple specialized machines, streamlining operations and reducing costs.

4. Improved Safety: By allowing operators to work from a safe distance, high reach demolition booms significantly enhance safety in tunnel construction. Operators can remain in the cab of the excavator while working on higher sections of the tunnel, reducing exposure to falling debris and other hazards. Additionally, the extended reach eliminates the need for workers to be in close proximity to unstable areas during excavation or demolition activities.

5. Enhanced Productivity: The combination of extended reach, precision, and versatility translates to increased productivity in tunnel construction projects. High reach demolition booms enable faster excavation rates, more efficient material removal, and reduced downtime associated with equipment changes or repositioning. This increased efficiency can lead to significant time and cost savings over the course of a tunnel project.

How does a high reach demolition boom improve efficiency in confined spaces?

Tunnel construction often involves working in confined spaces, which can pose significant challenges for traditional excavation equipment. The excavator high reach demolition long boom and arm offers several advantages that improve efficiency in these restricted environments:

1. Optimized Maneuverability: High reach demolition booms are designed with articulated joints that allow for greater flexibility and maneuverability in tight spaces. This design enables operators to navigate around obstacles and work in areas with limited headroom, which is particularly beneficial in tunnel construction where space is often at a premium.

2. Reduced Equipment Repositioning: The extended reach of these booms minimizes the need for frequent repositioning of the excavator. In confined tunnel spaces, moving heavy equipment can be time-consuming and potentially dangerous. By reducing the frequency of these movements, high reach demolition booms contribute to improved efficiency and safety.

3. Enhanced Material Removal: In tunnel construction, efficient material removal is crucial for maintaining progress. High reach demolition booms can be equipped with specialized buckets and attachments designed for optimal material handling in confined spaces. These attachments, combined with the boom's extended reach, allow for more efficient loading of haul trucks or conveyor systems, reducing cycle times and improving overall productivity.

4. Improved Visibility: Many high reach demolition booms are equipped with advanced camera systems that provide operators with clear views of the work area, even in poorly lit tunnel environments. This enhanced visibility contributes to improved accuracy and efficiency, as operators can make more informed decisions about material removal and excavation strategies.

5. Adaptability to Changing Conditions: Tunnel construction often involves working through various geological formations and conditions. High reach demolition booms can be quickly adapted with different attachments to handle changing ground conditions, from soft soil to hard rock. This adaptability ensures that work can continue efficiently without the need for major equipment changes or delays.

How to ensure safety when using a high reach demolition long boom in tunnels?

While the excavator high reach demolition long boom and arm offers numerous safety advantages, it's crucial to implement proper safety protocols to maximize its benefits and minimize risks. Here are key considerations for ensuring safety when using these specialized booms in tunnel construction:

1. Operator Training: Comprehensive training is essential for operators using high reach demolition booms in tunnel environments. This training should cover not only the operation of the equipment but also specific safety protocols related to tunnel construction. Operators should be well-versed in recognizing potential hazards and understanding the limitations of the equipment.

2. Regular Equipment Inspections: Before each use, the high reach demolition boom and its attachments should undergo thorough inspections. This includes checking hydraulic systems, structural components, and safety features. Regular maintenance schedules should be strictly adhered to, with any issues addressed promptly by qualified technicians.

3. Stability Considerations: The extended reach of these booms can affect the stability of the excavator, particularly when working at maximum extension. It's crucial to ensure that the machine is properly stabilized and that operators are aware of load limits and tipping points. In tunnel environments, this may involve the use of additional outriggers or careful positioning of the excavator.

4. Communication Systems: Effective communication is vital in tunnel construction. Implementing reliable communication systems between operators, ground crew, and supervisors can help prevent accidents and improve overall safety. This may include two-way radios, hand signals, or advanced wireless communication systems.

5. Personal Protective Equipment (PPE): All personnel working in the vicinity of high reach demolition operations should wear appropriate PPE, including hard hats, safety glasses, high-visibility clothing, and steel-toed boots. In tunnel environments, additional PPE such as respiratory protection may be necessary depending on air quality and dust levels.

6. Environmental Monitoring: Tunnel construction can present unique environmental hazards, including poor air quality and the potential for gas build-up. Implementing a robust environmental monitoring system, including air quality sensors and gas detectors, is crucial for ensuring the safety of all personnel working with high reach demolition equipment in tunnels.

7. Emergency Response Planning: Develop and regularly review emergency response plans specific to high reach demolition operations in tunnel environments. These plans should include procedures for equipment failure, tunnel collapse, fire, and medical emergencies. Regular drills and simulations can help ensure that all personnel are prepared to respond effectively in case of an emergency.

8. Load Management: Proper load management is critical when using high reach demolition booms in tunnels. Operators must be trained to assess and manage loads effectively, considering factors such as material density, attachment weight, and boom extension. Implementing load monitoring systems can provide real-time feedback to operators, helping prevent overloading and potential accidents.

9. Lighting and Visibility: Adequate lighting is essential for safe operations in tunnel environments. Ensure that the work area is well-lit, and consider equipping the high reach demolition boom with additional lighting systems to improve visibility. Reflective markers or paint on the boom can also enhance visibility and spatial awareness in low-light conditions.

10. Regular Safety Audits: Conduct regular safety audits specific to high reach demolition operations in tunnel construction. These audits should assess compliance with safety protocols, identify potential hazards, and recommend improvements to safety procedures. Involving operators and ground crew in these audits can provide valuable insights and foster a culture of safety.

Excavator High Reach Demolition Long Boom And Arm For Sale

The excavator high reach demolition long boom and arm has proven to be an invaluable tool in tunnel construction, offering extended reach, improved efficiency, and enhanced safety. By understanding its capabilities and implementing proper safety protocols, contractors can maximize the benefits of this specialized equipment in their tunnel projects.

If you're in the market for high-quality excavator high reach demolition long booms, look no further than Tiannuo Machinery. As a leading manufacturer and supplier specializing in the production of excavator long booms and arms, we offer innovative solutions tailored to the unique demands of tunnel construction.

Our excavator tunnel arms are specially designed to address the challenges of limited space in tunnel construction. With a shortened design, our arms can adapt to the special needs of tunnel working conditions, allowing for rotating work in narrow spaces. Equipped with enlarged buckets and breaker hammers, these tunnel-specific arms are crafted from high-strength manganese steel, ensuring durability and efficiency in even the most demanding crushing environments.

Ready to elevate your tunnel construction capabilities? Contact our team of experts today to discuss your specific needs and find the perfect excavator high reach demolition long boom for your project. Reach out to our manager at arm@stnd-machinery.com, or connect with our team members at rich@stnd-machinery.com and tn@stnd-machinery.com. Let Tiannuo Machinery be your partner in achieving new heights of efficiency and safety in tunnel construction.

References:

- Occupational Safety and Health Administration. (2021). "Excavation and Trenching Safety."

- Construction Equipment. (2020). "Precision Excavation Techniques for Tunneling Projects."

- International Tunnelling and Underground Space Association. (2019). "Mechanized Tunnelling in Urban Areas."

- Journal of Construction Engineering and Management. (2018). "Safety Management in Tunnel Construction: A Case Study."

- Tunnelling Journal. (2021). "Productivity Gains in Modern Tunnel Construction."

- Tunnels and Tunnelling International. (2020). "Innovative Equipment for Confined Space Excavation."