What are the extension arms on an excavator called?

In the world of construction and earthmoving, excavators play a crucial role in various projects. These powerful machines are known for their versatility and efficiency, thanks in large part to their ability to reach and dig in areas that would otherwise be inaccessible. One of the key components that enables this versatility is the excavator extension arm. In this comprehensive guide, we'll explore what excavator extension arms are, their types, and how they work, providing valuable insights for both industry professionals and enthusiasts alike.

What is an excavator extension arm?

An excavator extension arm, also known as a long reach arm or extended reach arm, is a specialized attachment designed to increase the reach and dig depth of an excavator. This crucial component allows operators to access areas that would be impossible to reach with a standard arm, significantly enhancing the machine's capabilities and versatility.

Excavator extension arms are typically made of high-strength steel to withstand the stresses of heavy-duty operations. They are engineered to maintain the excavator's stability and performance while providing extended reach. These arms can be fitted to various sizes of excavators, from compact models to large, heavy-duty machines, making them invaluable tools across a wide range of construction and earthmoving projects.

The primary purpose of a long-reach arm is to allow the machine to work at greater distances or depths without the need to reposition the excavator itself. This capability is particularly useful in scenarios such as:

- Dredging operations in deep water bodies

- Excavating at the bottom of steep slopes

- Demolition work on tall structures

- Clearing vegetation from hard-to-reach areas

- Digging deep trenches or foundations

By enabling these diverse applications, excavator extension arms significantly increase the efficiency and productivity of construction projects, reducing the need for specialized equipment or multiple machine setups.

What are the types of excavator extension arms?

Excavator extension arms come in various types, each designed to meet specific operational needs and challenges. Understanding these different types can help project managers and operators choose the most suitable option for their particular requirements. Let's explore some of the most common types of long reach arms:

1. Fixed Long Reach Arms

Fixed long reach arms are the most straightforward type of extension arm. As the name suggests, these arms have a fixed length and cannot be adjusted during operation. They are typically used when a consistent, extended reach is required throughout a project. Fixed long reach arms are popular in applications such as:

- River dredging

- Pond cleaning

- Excavating deep foundations

While they offer excellent stability and strength, the trade-off is reduced flexibility compared to other types of extension arms.

2. Telescopic Arms

Telescopic arms offer a more versatile solution, allowing operators to adjust the arm's length during operation. These arms consist of multiple sections that can extend and retract, providing a range of reach options. Telescopic arms are particularly useful in scenarios where varying reach is required, such as:

- Demolition work at different heights

- Excavating on uneven terrain

- Clearing debris from hard-to-reach areas

The ability to adjust the arm's length on-the-fly makes telescopic arms highly adaptable to changing work conditions.

3. Articulated Arms

Articulated arms, also known as knuckle boom arms, feature additional joints that allow for greater flexibility and maneuverability. These arms can bend at multiple points, enabling operators to navigate around obstacles and work in confined spaces. Articulated arms are particularly valuable in:

- Urban construction sites with limited space

- Demolition projects requiring precise control

- Landscaping operations in complex terrain

The enhanced flexibility of articulated arms comes at the cost of slightly reduced lifting capacity compared to fixed arms of similar length.

4. Modular Extension Systems

Modular extension systems offer a customizable solution, allowing operators to add or remove sections to achieve the desired reach. These systems typically consist of a base arm and multiple extension pieces that can be connected as needed. Modular systems are advantageous in situations where:

- Projects require varying reach capabilities

- Transportation of equipment between sites is a concern

- Versatility is prioritized over maximum reach

While modular systems offer unparalleled flexibility, they may require more setup time compared to fixed or telescopic arms.

5. Specialty Arms

In addition to these common types, there are also specialty arms designed for specific applications. These may include:

- High-rise demolition arms for tall building deconstruction

- Underwater excavation arms for marine projects

- Ultra-long reach arms for large-scale dredging operations

These specialty arms are typically custom-designed for particular industries or project types, offering optimized performance for their intended use.

The choice of excavator extension arm type depends on various factors, including the nature of the project, site conditions, budget constraints, and the specific capabilities required. By carefully considering these factors, project managers can select the most appropriate extension arm to maximize efficiency and productivity.

How does an excavator extension arm work?

Understanding the mechanics of how an excavator extension arm works is crucial for operators and project managers alike. This knowledge not only aids in proper operation but also helps in maintenance and troubleshooting. Let's delve into the key components and principles that enable long reach arms to function effectively.

Components of an Excavator Extension Arm

An excavator extension arm typically consists of several key components:

- Main Arm: This is the primary structural element of the extension arm, usually made of high-strength steel to withstand heavy loads and stresses.

- Hydraulic Cylinders: These provide the force necessary to move and control the arm.

- Pivot Points: These allow for the articulation of the arm, enabling it to move in various directions.

- Bucket or Attachment: At the end of the arm, various tools can be attached, such as buckets, grapples, or hammers.

- Hydraulic Lines: These carry hydraulic fluid to power the cylinders and attachments.

- Control Valves: These regulate the flow of hydraulic fluid, allowing precise control of the arm's movements.

Hydraulic System

The heart of an excavator extension arm's operation is its hydraulic system. This system works on the principle of fluid dynamics, where pressurized hydraulic fluid is used to transmit power from the excavator's engine to the various components of the arm. Here's a simplified explanation of how it works:

- The excavator's engine powers a hydraulic pump, which pressurizes the hydraulic fluid.

- This pressurized fluid is directed through hydraulic lines to the control valves.

- The operator manipulates the control levers, which adjust the control valves.

- The valves regulate the flow of hydraulic fluid to the appropriate cylinders.

- As the cylinders fill with or release hydraulic fluid, they extend or retract, moving the arm.

This system allows for precise control of the arm's movements, enabling operators to perform delicate operations with a high degree of accuracy.

Load Balancing and Stability

One of the challenges with excavator extension arms is maintaining the machine's stability, especially when working at maximum reach. To address this, extension arms are designed with several features:

- Counterweights: Additional weight is often added to the rear of the excavator to balance the extended arm.

- Outriggers: Some excavators equipped with long reach arms have extendable stabilizers to increase the machine's footprint and stability.

- Load Sensing Systems: Advanced excavators may include sensors that monitor the load and adjust the hydraulic pressure accordingly to prevent tipping.

These features work together to ensure the excavator remains stable even when the extension arm is fully extended and under load.

Control Systems

Modern excavator extension arms often incorporate advanced control systems to enhance precision and efficiency. These may include:

- Joystick Controls: Allowing for intuitive operation of the arm.

- Computer-Aided Systems: Providing real-time feedback on arm position and load.

- Automated Functions: Such as return-to-dig or boom height control.

These control systems help operators work more efficiently and safely, especially when performing repetitive tasks or working in challenging conditions.

Maintenance Considerations

To ensure the proper functioning of an excavator extension arm, regular maintenance is crucial. This typically involves:

- Regular inspection of hydraulic components for leaks or wear

- Lubrication of pivot points and moving parts

- Checking and replacing hydraulic fluid as needed

- Inspecting the structural integrity of the arm for any signs of stress or damage

Proper maintenance not only ensures optimal performance but also extends the lifespan of the extension arm and the excavator as a whole.

By understanding how excavator extension arms work, operators can maximize their efficiency and safety on the job site. This knowledge also aids in troubleshooting issues and making informed decisions about equipment selection for specific projects.

Excavator Extension Arm For Sale

At Tiannuo Machinery, we offer a range of high-quality excavator extension arms designed to meet diverse project needs. Our product line includes:

- 20-25 ton excavator: Extends to 16 meters, includes 8.5-meter extended long arm, 7.5-meter extended small arm.

- 25-34 ton excavator: Extends to 20 meters, includes 11-meter extended long arm, 9-meter extended small arm.

- 35-40 ton excavator: Extends to 22 meters, includes 12-meter extended long arm, 10-meter extended small arm.

- 40-50 ton excavator: Extends to 26 meters, includes 14-meter extended long arm, 12-meter extended small arm.

For detailed information or inquiries, please reach out to our management team at arm@stnd-machinery.com, or connect with our dedicated team members at rich@stnd-machinery.com and tn@stnd-machinery.com. At Tiannuo Machinery, we are committed to delivering excellence in railway maintenance solutions.

References

- Smith, J. (2021). "Excavator Technology: Advancements in Extension Arms." Construction Equipment Journal, 45(3), 78-85.

- Johnson, R. (2020). "Hydraulic Systems in Modern Excavators." Engineering Today, 12(2), 112-120.

- Brown, A. (2019). "Safety Considerations for Long Reach Excavators." International Journal of Construction Safety, 8(4), 201-215.

- Davis, M. (2022). "Comparative Analysis of Excavator Arm Types." Journal of Construction Engineering, 33(1), 45-58.

- Wilson, E. (2021). "Maintenance Protocols for Hydraulic Excavators." Industrial Maintenance & Plant Operation, 17(3), 92-101.

YOU MAY LIKE

VIEW MOREFront Loader Bucket

VIEW MOREFront Loader Bucket VIEW MOREExcavator Tree Stumper

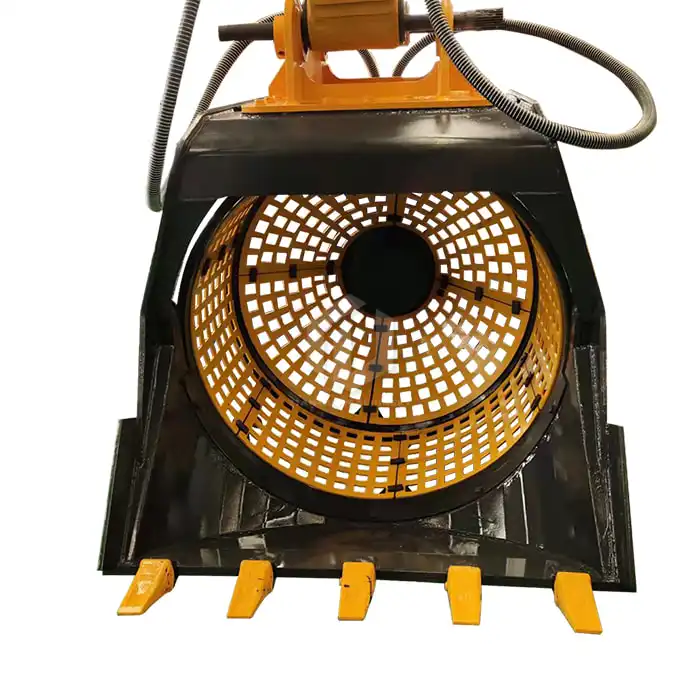

VIEW MOREExcavator Tree Stumper VIEW MOREExcavator Rotary Screening Bucket

VIEW MOREExcavator Rotary Screening Bucket VIEW MOREExcavator High Frequency Screening Bucket

VIEW MOREExcavator High Frequency Screening Bucket VIEW MOREExcavator High Altitude Demolition Arm

VIEW MOREExcavator High Altitude Demolition Arm VIEW MORESeaside Excavator Heightening Column

VIEW MORESeaside Excavator Heightening Column VIEW MOREUnloading Train Excavator Long Legs

VIEW MOREUnloading Train Excavator Long Legs VIEW MORERailway Excavator Ballast Plow

VIEW MORERailway Excavator Ballast Plow