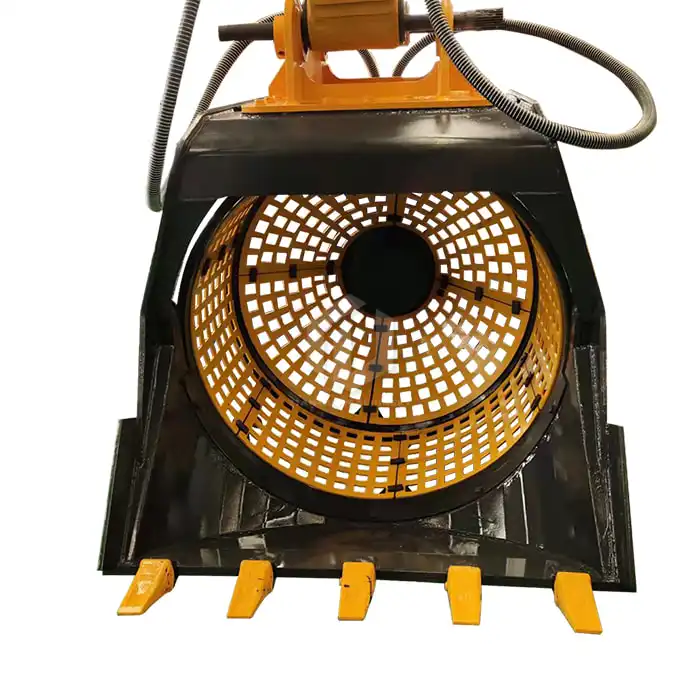

Excavator Gripper

Clamp Body: High-strength steel for durability.

Clamp Teeth: Adjustable for different tasks.

Oil Cylinder: Powers clamping via hydraulic oil.

Pipeline: Connects cylinder to control valve.

Operation: Hydraulic system controls clamp movement through pressure oil.

Applications: Used in excavation, demolition, ore extraction, and slope cleaning.

Maintenance: Regular checks on fasteners, lubrication, and performance ensure longe

- Product Description

- Specifications

What is an Excavator Gripper?

An Excavator Gripper is a powerful attachment designed to enhance the versatility and efficiency of excavators, particularly in handling, sorting, and processing materials like metal scrap, demolition debris, and industrial waste. These grippers are engineered to withstand harsh working conditions and are essential for operations that require precise and heavy-duty material handling.

With over 10 years of experience in the industry, Tiannuo has established itself as a leader in the manufacturing and supply of high-quality excavator gripper. Our commitment to innovation, precision engineering, and customer satisfaction sets us apart in the competitive landscape of construction and recycling equipment.

Excavator Gripper Key Features:

High Durability: Made from high-strength steel, our grippers are built to last, even under the most demanding conditions.

Efficient Material Handling: Capable of gripping and moving large volumes of material quickly and safely.

Versatile Design: Excavator Gripper is suitable for a wide range of applications, including scrap metal recycling, demolition, and waste management.

Low Maintenance: Designed for continuous operation with minimal maintenance requirements, reducing downtime and operational costs.

Customizable Options: We offer customization to meet the specific needs of your operations, from size adjustments to additional features.

How It Works

Our Excavator Grippers are attached to the arm of an excavator, transforming it into a powerful material-handling machine. The gripper is controlled by the hydraulic system of the excavator, allowing for precise and powerful gripping action. Whether you’re sorting metal scrap, handling demolition debris, or managing industrial waste, our grippers ensure that your operations are carried out efficiently and safely.

Workshop Display

At Tiannuo Machinery, our commitment to quality is exemplified by our cutting-edge manufacturing facility. Our workshop is a hub of advanced technology, meticulously designed to enhance every phase of our production process. Here, skilled professionals with extensive expertise oversee the creation of each gripper, adhering to rigorous quality benchmarks throughout.

Testimonials

John D., Operations Manager, XYZ Scrap Metal Recycling:

"Tiannuo’s gripper has transformed our operations. The efficiency and durability are unmatched, reducing our downtime significantly."

Sarah K., Demolition Contractor:

"The gripper’s versatility is incredible. It handles everything we throw at it with precision, making our jobs quicker and safer."

FAQ

Q: What types of materials can the Excavator Gripper?

A: Our grippers are designed to handle a wide range of materials, including metal scrap, demolition debris, and various industrial waste.

Q: Can the grippers be customized?

A: Yes, Tiannuo offers customization options to meet the specific needs of your operation, including size adjustments and additional features.

Q: What kind of maintenance is required?

A: Tiannuo’s grippers are low-maintenance, designed for continuous operation with minimal upkeep. Regular inspections and lubrication are recommended for optimal performance.

Q: How long is the delivery time?

A: Delivery times vary depending on the customization requirements, but we strive to ensure quick and efficient delivery for all our customers.

Contact Us

For more information on our Excavator Grippers or to request a quote, please contact us at rich@stnd-machinery.com orarm@stnd-machinery.com. Our team is ready to assist you with all your machinery needs.

Model | Max Opening Width (mm) | Weight (kg) | Hydraulic Pressure (MPa) | Operating Weight (Ton) |

|---|---|---|---|---|

| TG-200 | 2000 | 500 | 25-30 | 20-25 |

| TG-300 | 3000 | 700 | 25-30 | 25-30 |

| TG-400 | 4000 | 900 | 25-30 | 30-35 |