Comparison of the advantages of excavator high reach demolition long boom and other equipment at work

In the world of construction and demolition, efficiency and safety are paramount. As urban development continues to evolve, the need for specialized equipment capable of handling complex demolition projects has grown significantly. Enter the excavator high reach demolition long boom – a game-changing tool that has revolutionized the demolition industry. This article will explore how this innovative equipment compares to traditional demolition methods and why it's becoming the preferred choice for many contractors.

How does a high reach demolition long boom compare to standard excavator arms?

Standard excavator arms have been a staple in construction and demolition for decades. However, the excavator high reach demolition long boom offers several distinct advantages that set it apart from its conventional counterpart.

Firstly, the most obvious difference is in the name itself – the reach. High reach demolition long booms can extend significantly further than standard excavator arms, allowing operators to access heights that were previously challenging or impossible. This extended reach is particularly crucial when dealing with tall structures or buildings in confined urban spaces where traditional demolition methods may be impractical or unsafe.

Secondly, the design of high reach demolition long booms incorporates advanced hydraulic systems and reinforced structures. This allows for greater precision and control during demolition operations. Operators can manipulate the boom with a high degree of accuracy, ensuring that debris falls in predetermined areas, thereby enhancing safety and reducing the risk of collateral damage.

Another key advantage is versatility. While standard excavator arms are limited in their range of motion and attachment options, high reach demolition long booms can be equipped with a variety of tools. From hydraulic shears and crusher buckets to pulverizers and grapples, these attachments can be easily swapped out to tackle different aspects of a demolition project efficiently.

Moreover, the use of high reach demolition long booms often results in a more streamlined workflow. By allowing operators to work from a safe distance, these booms reduce the need for scaffolding or other temporary structures that are often required when using standard excavator arms for tall demolitions. This not only saves time but also significantly reduces labor costs and potential safety risks associated with working at heights.

What are the key advantages of high reach demolition long booms over wrecking balls?

Wrecking balls have long been synonymous with demolition work, often depicted in movies and television as the go-to method for bringing down buildings. However, the excavator high reach demolition long boom offers several advantages that make it a superior choice in many scenarios.

First and foremost is the issue of control. Wrecking balls rely on the momentum of a swinging mass to deliver destructive force, which can be unpredictable and difficult to direct precisely. In contrast, high reach demolition long booms offer operators a high degree of control. The hydraulic systems allow for precise movements, enabling operators to target specific areas of a structure with accuracy. This level of control is particularly valuable in urban environments where surrounding buildings need to be protected from collateral damage.

Safety is another crucial factor where high reach demolition long booms excel. Wrecking balls create significant amounts of dust and debris that can spread over a wide area, potentially endangering workers and bystanders. High reach demolition booms, on the other hand, allow for a more controlled demolition process. Operators can systematically dismantle structures from the top down, reducing the spread of debris and dust. This method also allows for better sorting of materials during demolition, facilitating recycling efforts.

Efficiency is yet another area where high reach demolition long booms outperform wrecking balls. While a wrecking ball might be effective for bringing down a structure quickly, it leaves behind a chaotic pile of mixed debris that requires significant time and effort to sort and remove. High reach demolition booms, with their various attachments, can sort materials as the demolition progresses, greatly streamlining the clean-up process.

Lastly, high reach demolition long booms are far more versatile than wrecking balls. While a wrecking ball is limited to swinging and impacting, a high reach boom can be fitted with different attachments to handle various aspects of demolition. From cutting steel beams to crushing concrete, these booms can adapt to the specific requirements of each project phase.

Is a high reach demolition long boom more efficient than hydraulic hammers?

Hydraulic hammers, also known as breakers, have been a popular tool in the demolition industry for many years. They are effective at breaking up concrete and other hard materials. However, when compared to the excavator high reach demolition long boom, there are several areas where the latter proves to be more efficient.

One of the primary advantages of high reach demolition long booms is their ability to work at greater heights. While hydraulic hammers are limited by the reach of the excavator arm they're attached to, high reach booms can extend much further. This means that operators can safely demolish tall structures without the need for additional equipment or putting workers at risk by working at heights.

In terms of versatility, high reach demolition long booms have a clear edge. While hydraulic hammers are specialized tools designed primarily for breaking, high reach booms can be equipped with a variety of attachments. This means that a single machine can perform multiple functions – from cutting steel beams to crushing concrete and sorting debris. This versatility not only increases efficiency but also reduces the number of machines needed on a job site, leading to cost savings.

Noise pollution is another factor to consider. Hydraulic hammers are notorious for their loud, repetitive impacts, which can be a significant issue in urban environments. High reach demolition long booms, especially when equipped with crusher or shear attachments, operate much more quietly. This makes them more suitable for use in noise-sensitive areas or during times when noise restrictions are in place.

When it comes to precision, high reach demolition long booms again have the upper hand. The hydraulic systems in these booms allow for very precise control, enabling operators to target specific areas of a structure. This level of precision is particularly valuable when working on partial demolitions or in situations where surrounding structures need to be preserved.

Lastly, the efficiency of high reach demolition long booms extends to the clean-up process. By allowing for a more controlled demolition from the top down, these booms can significantly reduce the amount of debris that needs to be sorted and removed from the site. This can lead to substantial time and cost savings in the overall project timeline.

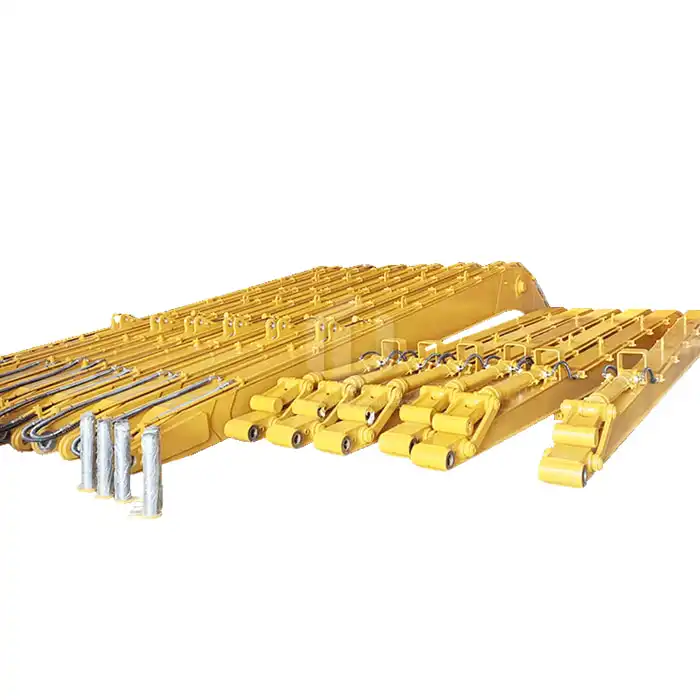

Excavator High Reach Demolition Long Boom And Arm For Sale

The excavator high reach demolition long boom represents a significant advancement in demolition technology. Its superior reach, precision, versatility, and efficiency make it an invaluable tool for modern demolition projects, especially in urban environments where safety and control are paramount.

Tiannuo Machinery is a leading manufacturer and supplier specializing in the production of excavator high reach demolition long boom. We understand the unique challenges of demolition work and have designed our products to meet these demanding requirements. Our excavator tunnel arm is a specialized attachment designed specifically for tunnel construction, featuring a shortened design to adapt to the limited space in tunnel working conditions.

Our tunnel-specific shortened arm can be equipped with an enlarged bucket and breaker hammer to meet the special needs of tunnel construction. Made from high-strength manganese steel, it's built to withstand severe crushing environments while providing superior efficiency.

If you're in the market for an excavator high reach demolition long boom or specialized tunnel arm, we invite you to reach out to us. Our team of experts is ready to assist you in finding the perfect solution for your project needs. Contact our manager at arm@stnd-machinery.com, or reach out to our team members at rich@stnd-machinery.com and tn@stnd-machinery.com. Let Tiannuo Machinery be your partner in efficient, safe, and productive demolition work.

References:

- Occupational Safety and Health Administration. (2021). Demolition: Construction in Reverse, with Additional Hazards.

- Diven, R. J., & Shaurette, M. (2010). Demolition: Practices, Technology, and Management.

- Kourmpanis, B., et al. (2008). Preliminary study for the management of construction and demolition waste. Waste Management & Research, 26(3), 267-275.

- Lingard, H., & Rowlinson, S. (2005). Occupational Health and Safety in Construction Project Management.

- Byles, J. (2005). Rubble: Unearthing the History of Demolition.