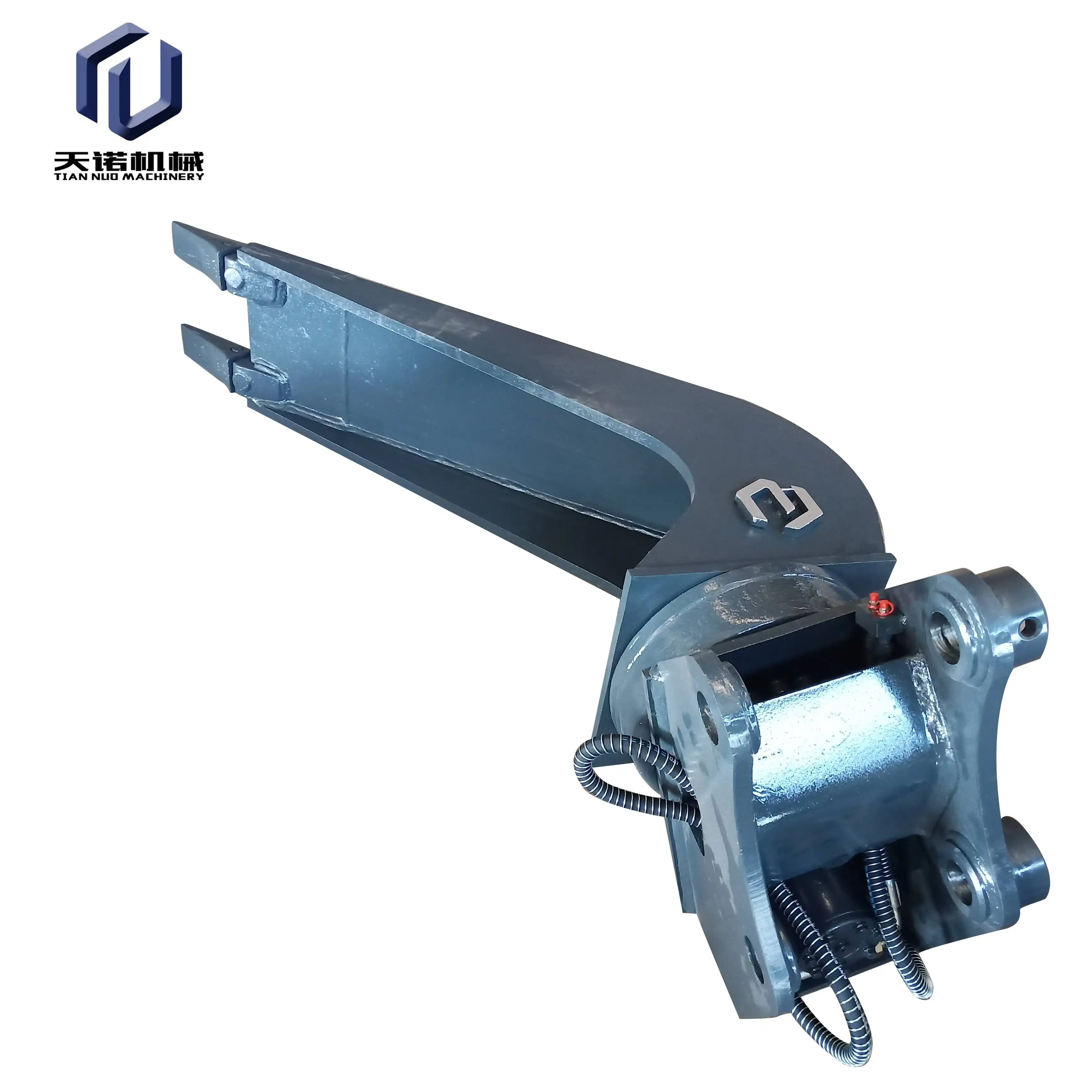

Excavator ballast cleaning hopper

2. Clean the ballast between the sleepers, which can quickly clean the ballast at the bottom of the steel rail slab"

- Product Description

1. About Tiannuo Machinery

Tiannuo Machinery is your reliable manufacturer and supplier of high-performance railway excavator attachments, with over 10 years of industry expertise. We specialize in providing Excavator Ballast Cleaning Hoppers designed to streamline ballast collection, separation, and re-distribution for railway construction and maintenance projects.

Whether you’re in construction, mining, waste management, or transport logistics, our ballast hoppers are engineered to handle large volumes, reduce manual labor, and support sustainable infrastructure development.

Why Choose Tiannuo?

- 🔧 OEM & Design Customization Available

- ⏱️ Fast Delivery, Even for Bulk Orders

- 📦 Export-Grade, Damage-Resistant Packaging

- 🏗️ Tailored Solutions for Specialized Rail Excavators

- 🌐 Global Support & Multilingual Service

2. What is an Excavator Ballast Cleaning Hopper?

An Excavator Ballast Cleaning Hopper is a specialized attachment designed for efficient screening, collection, and discharge of railway ballast (crushed stone or gravel that supports railway tracks).

Attached to a rail-capable excavator, this hopper enables:

- 🚄 On-track cleaning of contaminated or fouled ballast

- ♻️ Recycling of reusable ballast material

- ⛏️ Easy removal of fine particles, dust, and debris

This equipment enhances productivity on railway maintenance jobs by reducing the need for manual collection and eliminating the need for separate dump or loader trucks.

Ideal for:

- Railway engineering contractors

- Municipal rail maintenance divisions

- Infrastructure companies in need of high-volume material handling

3. Product Specifications

| Specification | Details |

|---|---|

| Product Name | Excavator Ballast Cleaning Hopper |

| Material | Wear-resistant steel with reinforced structure |

| Mounting System | Quick-coupler compatible with most rail excavators |

| Ballast Output Size | Adjustable via internal screen (varies by model) |

| Discharge Mechanism | Hydraulic or gravity discharge (optional gate control) |

| Screen Type | Removable mesh or rotating shaft design |

| Operating Method | Hydraulic control (integrated or separate line) |

| Power Source | Excavator hydraulic system |

| Compatibility | Rail-wheel excavators or dual-mode machines |

| Custom Design Support | Yes |

| Surface Treatment | Anti-corrosion & weatherproof coating |

| Lead Time | 10–25 working days (depending on volume & customization) |

4. Key Features

🔄 Efficient Material Separation

Built-in screen or shaker mechanism separates usable ballast from debris and fines.

🚚 Large Volume Hopper

High-capacity design enables fewer trips, faster project completion, and reduced idle time.

🛠️ Customizable Discharge Options

Choose from hydraulic-controlled chutes or manual gates to suit your work style.

🔧 Universal Excavator Fit

Works with all major excavator brands; adapters and couplers available for unique requirements.

🌀 Low Maintenance Design

Easy access to wear parts and minimal downtime between cleaning cycles.

🌍 Eco-Friendly Ballast Handling

Supports sustainability goals by reducing waste and reusing clean ballast on-site.

5. How It Works

Operating the ballast cleaning hopper is simple and efficient:

- Attach Hopper to your rail or dual-mode excavator using the quick-coupler system.

- Scoop or Load Ballast using the excavator arm or an external loader.

- Internal Screen Separates fine materials and debris as the hopper fills.

- Discharge Clean Ballast back onto the trackbed or into a container, truck, or side of the track via hydraulic or gravity-fed outlet.

- Repeat Cycle as needed. Operators can monitor the screening and discharge process in real-time.

This process reduces labor costs and eliminates the need for manual sorting and hauling, making it ideal for both small project crews and large-scale rail contractors.

6. Workshop Display

🏭 Inside Tiannuo’s modern facility, each hopper is:

- Laser-cut and precision-welded for strength and durability

- Tested under full load to ensure structural integrity

- Fitted with modular components for quick part replacement

- Inspected by ISO-certified quality control personnel

- Tailored to client rail gauges and excavator specs

Our workshop handles low-volume custom jobs as well as high-volume production runs with equal precision and care.

7. Testimonials

“This hopper saved us hours on every ballast clearing job. Minimal breakdowns and easy maintenance—just what our railway division needed.”

— Operations Supervisor, National Railway Authority (Germany)

“We used Tiannuo’s ballast hopper in a remote mining track project. Even after months of rugged use, the system worked like day one.”

— Project Manager, Mineral Transport Company (Chile)

“We asked for a special design to fit our narrow-gauge excavator. The custom solution delivered faster than expected—and worked perfectly.”

— Logistics Engineer, Regional Rail Systems (India)

8. FAQ

Q1: Is the hopper compatible with all excavators?

We design for standard and custom configurations. Simply share your machine model, and we’ll provide the appropriate mount or adapter.

Q2: What’s the screen size and can it be changed?

Yes, we offer removable or replaceable screens with different mesh sizes depending on your ballast size preference.

Q3: Can it be used in non-rail projects (e.g., road or mining)?

Yes, it’s suitable for any loose stone or gravel handling, including quarry and infrastructure projects.

Q4: What about spare parts and maintenance?

We stock common wear parts and offer fast replacements. Maintenance is minimal with easy-to-replace components.

Q5: Do you support on-site setup or training?

We provide setup guides, video tutorials, and remote tech support. On-site assistance is available upon request.

9. Why Tiannuo’s Ballast Cleaning Hopper Is Ideal for Your Project

No matter your industry—construction, railway, mining, or logistics—our Excavator Ballast Cleaning Hopper helps you:

- ✅ Boost project efficiency with faster ballast cleaning

- ✅ Reduce labor costs and improve safety

- ✅ Meet environmental and operational standards

- ✅ Get long-term value with rugged, low-maintenance design

- ✅ Work confidently with OEM support and expert service

Whether you’re a project-based buyer or a long-term equipment planner, Tiannuo delivers reliable, efficient, and customizable solutions that align with your operational goals.

Get a Quote or Design Consultation Today!

📩 Email us at:

_1742800072173.webp)

_1740558626327.webp)