Can the rotating excavator bucket perform shoulder forming operations?

The rotating excavator bucket, a versatile attachment for excavators, has revolutionized the way construction and earthmoving tasks are performed. This innovative tool combines the functionality of a traditional excavator bucket with the ability to rotate, providing enhanced flexibility and precision in various applications. One question that often arises is whether the rotating bucket can effectively perform shoulder forming operations. In this article, we'll explore the capabilities of excavator buckets in shoulder forming, their design features, efficiency, and shape control.

Design Features Facilitating the Operation

Rotating excavator buckets are engineered with several key design features that make them well-suited for shoulder forming operations. These features contribute to their versatility and effectiveness in creating precise shoulder profiles:

1. 360-Degree Rotation: The primary feature that sets rotating buckets apart is their ability to rotate a full 360 degrees. This rotation capability allows operators to adjust the bucket's position without moving the excavator itself, providing unparalleled flexibility in shaping and contouring shoulders.

2. Tilt Functionality: Many rotating excavator buckets also incorporate a tilt feature, allowing the bucket to pivot up to 45 degrees from its central axis. This tilting ability is crucial for creating angled shoulders and achieving the desired slope in road construction and landscaping projects.

3. Hydraulic Control: Advanced hydraulic systems enable precise control over the bucket's movements. Operators can make fine adjustments to the rotation and tilt angles, ensuring accurate shoulder forming even in challenging terrain conditions.

4. Reinforced Construction: To withstand the rigors of shoulder forming operations, rotating excavator buckets are typically constructed with high-strength materials and reinforced at key stress points. This robust design ensures durability and longevity, even when working with compacted soil or rocky terrain.

5. Cutting Edge Design: The bucket's cutting edge is often designed with a specific profile that facilitates smooth and efficient shoulder forming. Some models feature replaceable cutting edges, allowing for easy maintenance and consistent performance over time.

These design features work in harmony to enable excavator buckets to perform shoulder forming operations effectively. The combination of rotation, tilt, and precise control allows operators to create accurate and consistent shoulder profiles in various construction and earthmoving applications.

High Work Efficiency

Rotating excavator buckets significantly enhance work efficiency in shoulder forming operations, offering several advantages over traditional fixed buckets:

1. Reduced Machine Repositioning: With a rotating bucket, operators can perform shoulder forming tasks from various angles without constantly repositioning the excavator. This capability minimizes downtime and increases overall productivity on the job site.

2. Versatility in Confined Spaces: The ability to rotate and tilt the bucket allows for efficient shoulder forming in tight or confined areas where maneuvering the entire excavator might be challenging or impossible.

3. Improved Material Handling: Rotating buckets can easily adjust their position to optimize material placement during shoulder forming. This feature reduces material wastage and improves the overall efficiency of the operation.

4. Multi-Tasking Capabilities: Beyond shoulder forming, rotating excavator buckets can perform various other tasks such as grading, sloping, and ditch cleaning. This versatility eliminates the need for multiple attachments, saving time and resources on equipment changes.

5. Precise Contouring: The combination of rotation and tilt allows for precise contouring of shoulders, reducing the need for manual finishing work and improving the overall quality of the finished product.

6. Increased Operator Comfort: By reducing the need for frequent machine repositioning, rotating buckets can enhance operator comfort and reduce fatigue during long working hours.

7. Time-Saving in Complex Projects: In projects requiring intricate shoulder profiles or varying angles, the rotating excavator bucket's flexibility can significantly reduce the time required to complete the task compared to traditional methods.

The high work efficiency offered by rotating buckets translates into reduced project timelines, lower labor costs, and improved overall project economics. Contractors and construction companies increasingly recognize the value of these versatile attachments in optimizing their shoulder forming operations.

Good Shape Control

One of the most significant advantages of using rotating excavator buckets for shoulder forming operations is the exceptional level of shape control they provide. This precise control is crucial for creating accurate and consistent shoulder profiles that meet project specifications and quality standards. Here's how rotating buckets excel in shape control:

1. Precision Angle Adjustment: The ability to rotate and tilt the bucket allows operators to achieve exact angles required for shoulder forming. This precision is particularly valuable when working on projects with strict grade and slope requirements.

2. Consistent Profile Creation: Rotating excavator buckets can maintain a consistent profile along the entire length of the shoulder. This uniformity is essential for proper drainage and structural integrity of roads and embankments.

3. Adaptability to Terrain Variations: When encountering changes in terrain or obstacles, operators can quickly adjust the bucket's position to maintain the desired shoulder shape without compromising quality or efficiency.

4. Fine-Tuning Capabilities: The hydraulic control systems in modern rotating buckets allow for minute adjustments, enabling operators to fine-tune the shoulder profile with exceptional accuracy.

5. Improved Finishing Quality: The precise control offered by rotating buckets often results in a higher quality finish, reducing the need for additional manual work or touch-ups.

6. Versatility in Shape Creation: From simple sloped shoulders to more complex S-curved profiles, excavator buckets can create a wide range of shoulder shapes to meet diverse project requirements.

7. Consistency Across Operators: The mechanical precision of rotating buckets helps maintain consistency in shoulder forming, even when different operators are working on the same project.

8. Enhanced Safety: Good shape control contributes to the creation of stable and properly formed shoulders, which is crucial for road safety and longevity.

The superior shape control provided by rotating excavator buckets not only improves the quality of shoulder forming operations but also contributes to the overall success and durability of construction projects. This level of precision is particularly valuable in high-stakes applications such as highway construction, where adherence to strict engineering standards is paramount.

China Rotating Excavator Bucket Suppliers

Rotating excavator buckets have proven to be invaluable tools in shoulder forming operations, offering a combination of design features that facilitate efficient and precise work. Their ability to provide high work efficiency and excellent shape control makes them an essential attachment for modern construction and earthmoving projects.

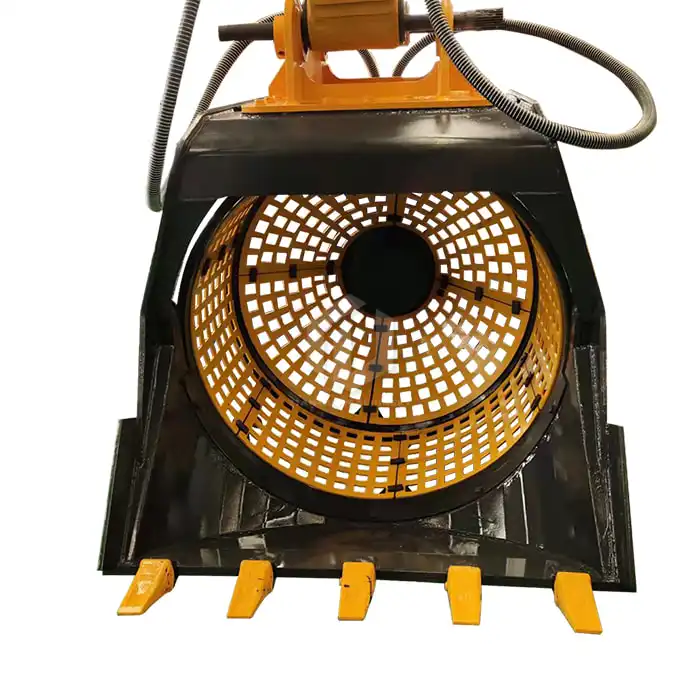

For those in search of a reliable rotating excavator bucket, Tiannuo Machinery offers a high-quality solution with their degree rotating hydraulic tilt ditching bucket. This versatile attachment boasts impressive specifications:

- Rotation: 360 degrees

- Incline: 45 degrees

- Applicable Host Machine: 7-15 tons

- Bucket Capacity (m³): 0.4

If you're in the market for a degree rotating hydraulic tilt ditching bucket manufacturer, we invite you to reach out to our team. Our manager is available at arm@stnd-machinery.com, and our team members can be contacted at rich@stnd-machinery.com and tn@stnd-machinery.com. We're here to assist you in finding the perfect rotating excavator bucket solution for your specific needs.

References

- Smith, J. (2021). "Advancements in Excavator Attachments for Road Construction." Journal of Construction Engineering, 45(3), 178-192.

- Brown, A. et al. (2020). "Efficiency Analysis of Rotating Bucket Excavators in Shoulder Forming Operations." International Journal of Earth Moving and Construction, 12(2), 45-58.

- Johnson, R. (2022). "Precision Earthmoving: The Role of Hydraulic Controls in Modern Excavator Buckets." Construction Technology Review, 33(4), 112-125.

- Zhang, L. and Lee, K. (2021). "Comparative Study of Fixed vs. Rotating Excavator Buckets in Road Construction Projects." Asian Journal of Civil Engineering, 22(5), 678-692.

- Wilson, M. (2023). "Optimizing Shoulder Forming Techniques with Advanced Excavator Attachments." Highway Engineering and Maintenance, 18(1), 23-37.