What industries do China's excavator rock arm suppliers serve?

Excavator rock arms, also known as rock breaker booms or hydraulic breaker booms, are essential attachments for various industries that require heavy-duty demolition, excavation, and material handling. These versatile tools, provided by China excavator rock arm suppliers, have revolutionized operations across multiple sectors. In this comprehensive article, we'll explore the diverse industries served by these suppliers and delve into the specific applications and benefits of excavator rock arms in different fields.

The Mining Industry: Enhancing Operational Efficiency with Excavator Rock Arms

The mining industry is one of the primary beneficiaries of excavator rock arms supplied by Chinese manufacturers. These robust attachments play a crucial role in improving operational efficiency and productivity in mining operations. Here's how the mining sector utilizes excavator rock arms:

Oversize Rock Breaking: In open-pit mines, excavator rock arms are used to break down oversized boulders that are too large for primary crushers. This process, known as secondary breaking, helps maintain a consistent flow of material through the crushing circuit, reducing downtime and increasing overall productivity.

Tunnel Development: In underground mining operations, excavator rock arms assist in tunnel development by breaking through hard rock formations. This application is particularly useful in areas where drilling and blasting may not be feasible or cost-effective.

Scaling and Rock Stabilization: Mining safety is paramount, and excavator rock arms play a vital role in scaling loose rocks from tunnel walls and ceilings. This process helps prevent rock falls and ensures a safer working environment for miners.

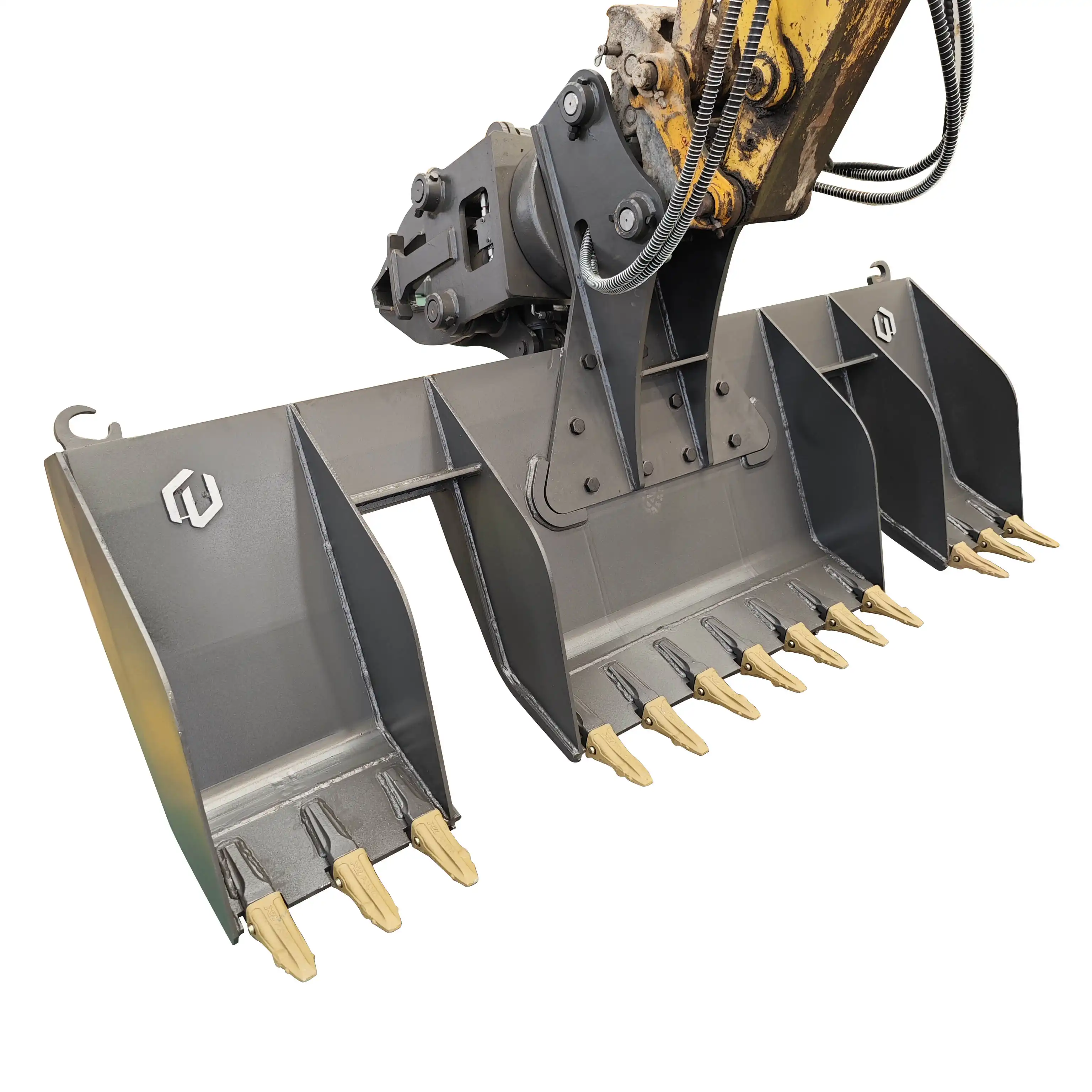

Material Handling: Some excavator rock arms are equipped with grapples or buckets, allowing them to handle and sort various materials in the mining process. This versatility contributes to more efficient material management on-site.

By incorporating excavator rock arms into their operations, mining companies can significantly improve their operational efficiency. These attachments allow for faster rock breaking, reduced manual labor, and enhanced safety measures. Additionally, the precision and reach of excavator rock arms enable miners to access difficult areas, increasing the overall extraction potential of a site.

Infrastructure Projects: The Role of Excavator Rock Arms in Construction

Infrastructure development is another key sector where China excavator rock arm suppliers make a significant impact. From road construction to urban renewal projects, these versatile attachments play multiple roles:

Road Construction: In road building projects, especially in mountainous or rocky terrain, excavator rock arms are used to clear obstructions and create level surfaces. They're particularly useful in cutting through rock formations to establish road beds.

Bridge Building: During bridge construction, excavator rock arms assist in foundation preparation by breaking up bedrock and clearing debris. They're also used in demolition phases when older structures need to be removed.

Tunnel Construction: Similar to their application in mining, excavator rock arms are crucial in tunnel construction for infrastructure projects. They're used to excavate rock, create precise profiles, and assist in support installation.

Urban Renewal: In urban areas, excavator rock arms are employed in demolition work, helping to clear old structures and prepare sites for new development. Their precision allows for selective demolition, preserving adjacent structures when necessary.

Utility Installation: When laying pipelines or cables in rocky terrain, excavator rock arms can efficiently create trenches and clear obstacles, speeding up the installation process.

The role of excavator rock arms in infrastructure projects is multi-faceted. They not only accelerate the construction process but also enhance precision and safety. By allowing operators to work from a distance, these attachments reduce the risks associated with manual rock breaking and demolition. Moreover, the ability to switch between different attachments on the same excavator base machine provides flexibility and cost-efficiency for construction companies.

Rock Crushing Operations: Maximizing Efficiency with Excavator Rock Arms

The quarrying and aggregate production industry is another sector that greatly benefits from the capabilities of excavator rock arms. China excavator rock arm suppliers provide solutions that streamline various aspects of rock crushing operations:

Primary Breaking: Before rocks enter the primary crusher, excavator rock arms are used to break down oversized boulders. This pre-crushing step helps prevent blockages in the crusher and ensures a more consistent feed size.

Clearing Crusher Blockages: When crushers become jammed with oversized or oddly shaped rocks, excavator rock arms can safely and efficiently clear these blockages without the need for manual intervention.

Selective Material Extraction: In quarries with varying rock qualities, excavator rock arms allow operators to selectively extract and sort materials based on their characteristics. This precision improves the overall quality of the final product.

Secondary Breaking: After primary crushing, some rocks may still be too large for secondary crushers. Excavator rock arms are used for this secondary breaking process, further reducing the size of rocks and improving crusher efficiency.

Site Preparation and Maintenance: Excavator rock arms assist in preparing and maintaining quarry sites, including scaling quarry faces, creating access roads, and managing overburden.

The benefits of using excavator rock arms in rock crushing operations are numerous. They significantly reduce the need for explosives, which can be costly and require special permits. The precision of these attachments also allows for better control over the size of broken material, leading to more efficient crushing and less wear on primary crushers. Furthermore, the ability to operate from a safe distance improves worker safety in what can be a hazardous environment.

Excavator rock arms have also proven valuable in recycling operations, particularly in the processing of construction and demolition waste. They can be used to break down large concrete pieces, separate rebar, and sort materials, contributing to more efficient recycling processes and supporting sustainability initiatives in the construction industry.

China Excavator Rock Arm Suppliers

China's excavator rock arm suppliers have become integral to various industries worldwide, providing essential tools for mining, infrastructure development, and rock crushing operations. These versatile attachments enhance operational efficiency, improve safety, and contribute to more sustainable practices across sectors.

As technology continues to advance, we can expect to see further innovations in excavator rock arm design and capabilities. These may include improved energy efficiency, enhanced precision through AI and machine learning integration, and the development of more specialized attachments for niche applications.

For businesses operating in these industries, partnering with reliable China excavator rock arm suppliers can provide a significant competitive advantage. By leveraging the power and versatility of these attachments, companies can improve their operational efficiency, reduce costs, and tackle challenging projects with greater confidence.

If you are choosing your excavator rock arm supplier, please feel free to reach out to our manager at arm@stnd-machinery.com and the team at rich@stnd-machinery.com and tn@stnd-machinery.com.

References

- Mining Technology. (2021). "The Role of Rock Breakers in Modern Mining Operations."

- International Journal of Mining Science and Technology. (2019). "Advancements in Tunnel Development Techniques."

- Safety Science. (2020). "Risk Management in Underground Mining: The Importance of Scaling."

- Journal of Cleaner Production. (2018). "Efficient Material Handling in Mining: A Review of Current Practices."

- Construction and Building Materials. (2017). "Innovative Techniques in Road Construction on Rocky Terrain."

- Structure and Infrastructure Engineering. (2019). "Modern Methods in Bridge Construction and Demolition."

YOU MAY LIKE

VIEW MOREExcavator Railway Slope Cleaning Machine

VIEW MOREExcavator Railway Slope Cleaning Machine VIEW MOREHigh-vibration hydraulic ballast tamping machine

VIEW MOREHigh-vibration hydraulic ballast tamping machine VIEW MOREExcavator Hydraulic Rail Clamp

VIEW MOREExcavator Hydraulic Rail Clamp VIEW MOREDump truck anti-skid tracks

VIEW MOREDump truck anti-skid tracks VIEW MORERailway excavator dustpan bucket

VIEW MORERailway excavator dustpan bucket VIEW MORETruck Anti-Skid Track

VIEW MORETruck Anti-Skid Track VIEW MOREExcavator Tree Stumper

VIEW MOREExcavator Tree Stumper VIEW MOREClamshell Bucket

VIEW MOREClamshell Bucket