Rail-Road Ballast Undercutter Excavator

- Product Description

About Tiannuo Machinery

At Tiannuo Machinery, we bring over 10 years of manufacturing experience to the railway maintenance equipment industry. Our expertise lies in designing and producing Rail-Road Ballast Undercutter Excavators that meet the evolving demands of modern railway systems.

With a customer base across construction, mining, environmental management, and logistics, we’ve built our reputation on:

- Customized Solutions for specific track conditions

- OEM Support for branding and specifications

- Fast Delivery & Strict Packaging

- End-to-End Design and Technical Support

2. What Is a Rail-Road Ballast Undercutter Excavator?

A Rail-Road Ballast Undercutter Excavator is a specialized piece of maintenance equipment used in railway operations to remove, clean, and redistribute ballast—the crushed stone beneath railway tracks. Over time, ballast becomes compacted or contaminated, affecting track stability and drainage.

Our undercutters are mounted on rail-compatible excavators, offering high-efficiency ballast excavation without dismantling the rail line. Perfect for on-site maintenance, track extension projects, and railway rehabilitation, these machines help optimize track integrity and safety.

3. Product Specifications

| Specification | Detail |

|---|---|

| Product Name | Rail-Road Ballast Undercutter Excavator |

| Base Machine Compatibility | Rail-road excavators (customizable) |

| Undercutting Depth | Up to 800mm |

| Undercutting Width | 500mm – 1200mm |

| Working Speed | 0.5 – 1.2 km/h (adjustable) |

| Rail Gauge Compatibility | 1435mm (standard) or custom |

| Material | High-strength steel & wear-resistant alloys |

| Hydraulic System | Integrated with excavator (customizable) |

| Control Type | Manual or automatic (optional upgrade) |

| OEM Support | Available |

| Delivery Time | 10–20 business days |

| Packaging | Export-grade wooden crates + film wrap |

4. Key Features

✅ High-Precision Ballast Cleaning

Removes compacted and contaminated ballast beneath sleepers without disturbing the rail line.

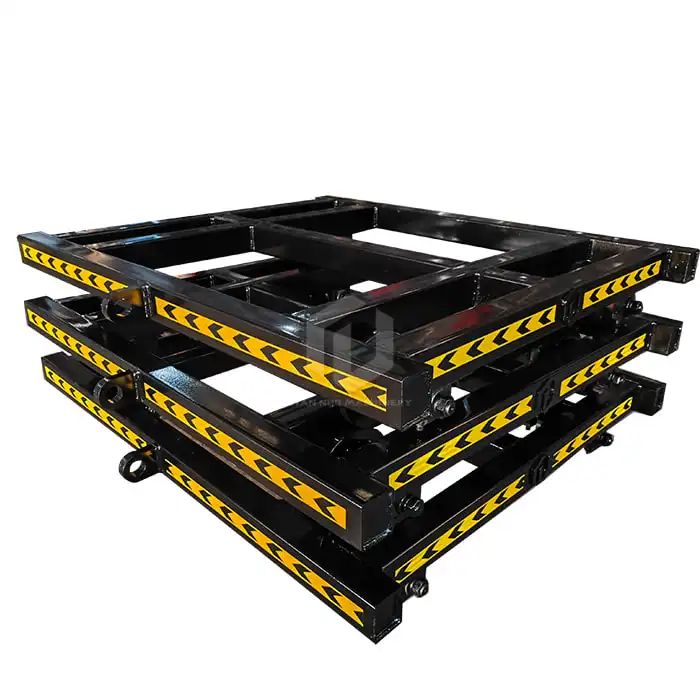

✅ Dual-Mode Mobility

Designed for railway and ground use, the undercutter adapts seamlessly between transport and operation modes.

✅ Built for Tough Conditions

Made from abrasion-resistant alloys, the tool withstands long-term use in demanding environments like quarries or wet regions.

✅ Custom-Fit for Global Tracks

Whether you're operating in Europe, North America, or Asia, we tailor the design to match rail gauge, working height, and machine compatibility.

✅ Eco-Friendly Design

Reduces the need for full ballast replacement, supporting sustainable rail maintenance practices.

5. How It Works

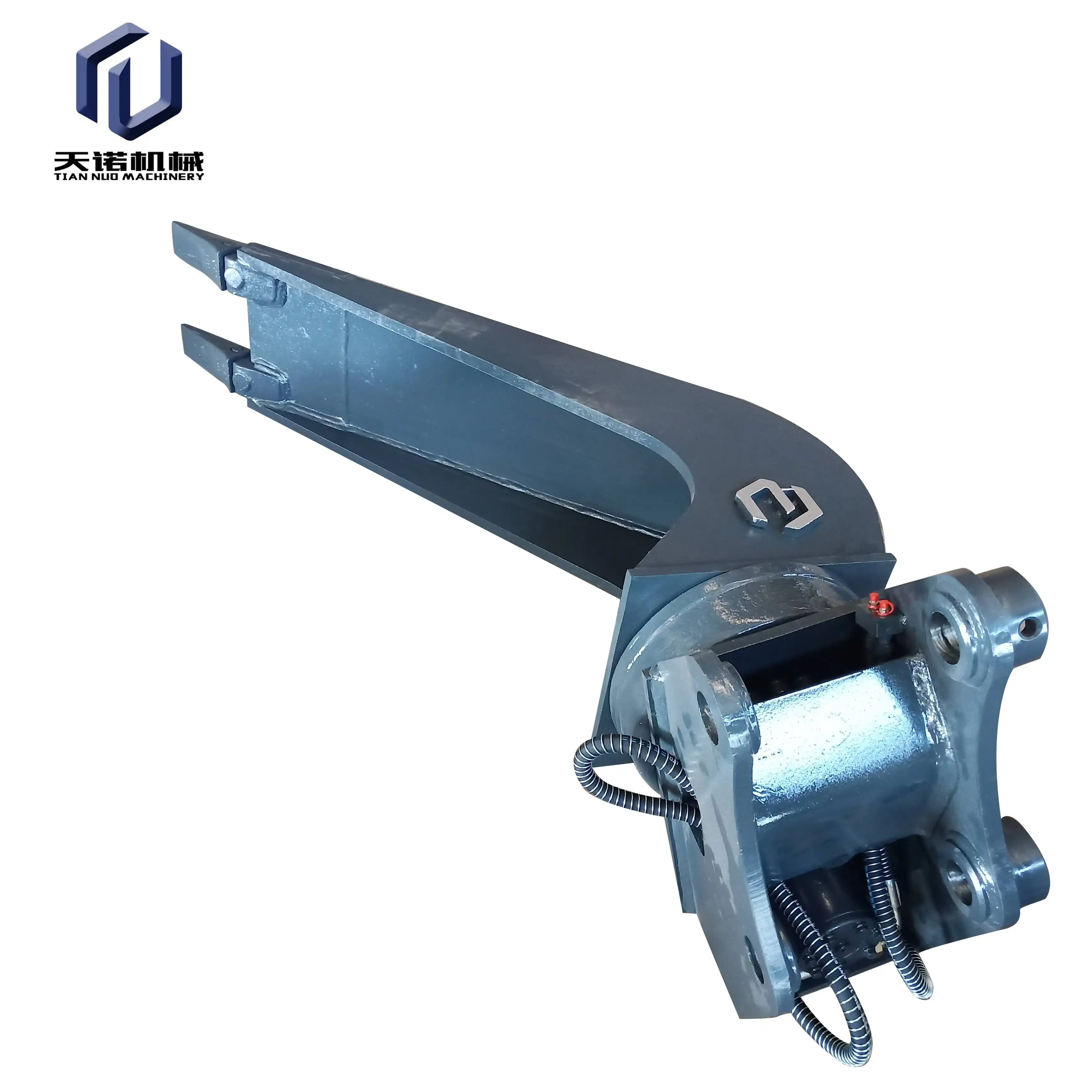

The Rail-Road Ballast Undercutter Excavator uses a hydraulically powered cutting chain or blade system that slides beneath the sleepers to excavate and clear fouled ballast.

Here’s how it improves your maintenance workflow:

- Mounting: Attach to rail-road excavator using quick coupling.

- Positioning: Lower the undercutter beneath the rail ties/sleepers.

- Operation: The undercutting system slices through compacted ballast, pushing it out for cleaning or replacement.

- Backfilling: Cleaned ballast is either returned to the track or replaced with new material.

With precise depth control, the system ensures minimal disruption to sleepers and track geometry.

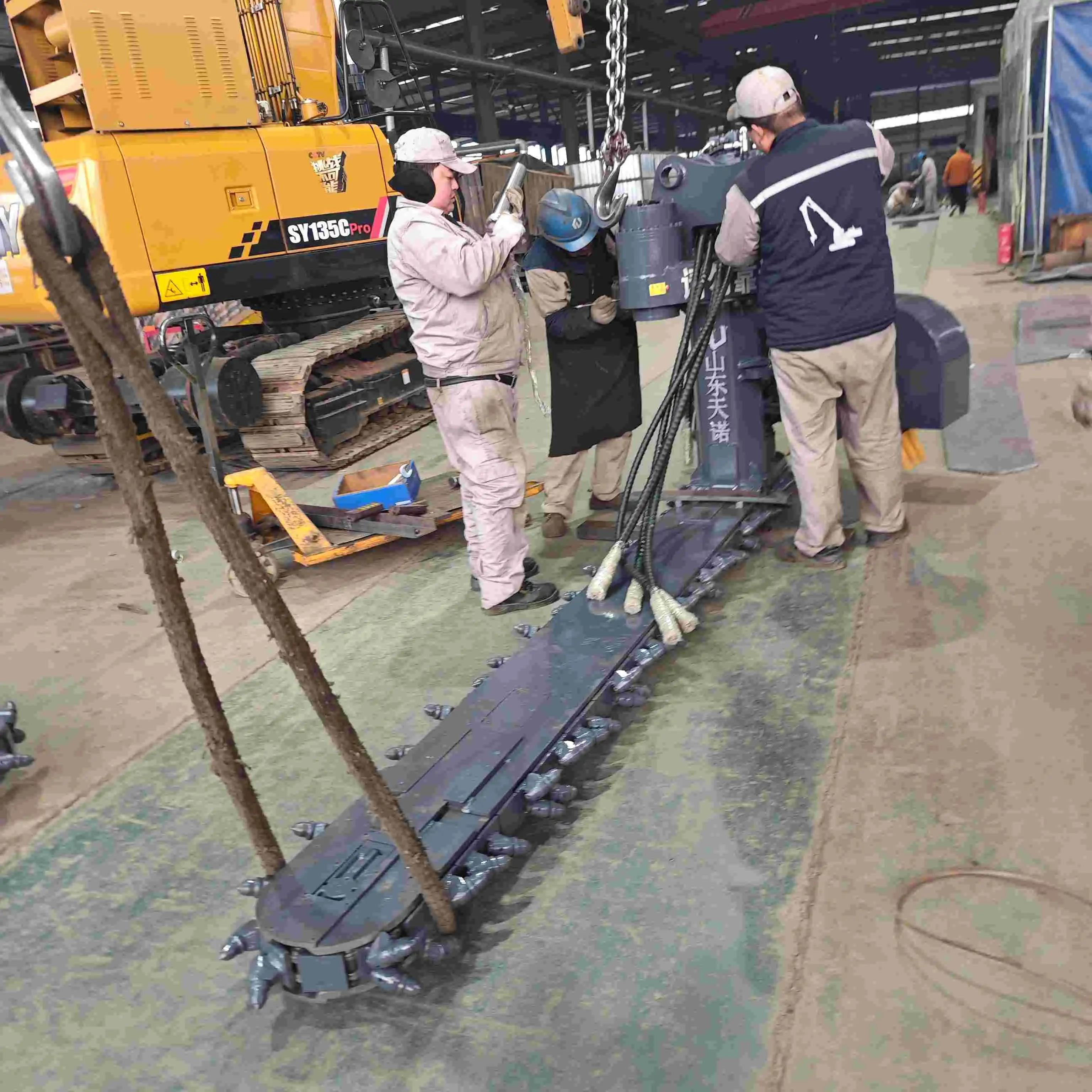

6. Workshop Display

🏭 At Tiannuo’s workshop, our production line includes:

- CNC Machining Centers for high-precision cutting head fabrication

- Welding Robots to ensure frame strength and consistency

- Quality Control Labs with hydraulic pressure and endurance testing

- On-site Rail Compatibility Testing Area

Every machine is thoroughly tested before shipment to guarantee performance and safety.

7. Customer Testimonials

“Reliable and efficient. Tiannuo’s ballast undercutter halved our rail line maintenance time. Highly recommended for any serious rail operator.”

— Maintenance Manager, Rail Infrastructure Company (Germany)

“We needed a custom unit for our narrow gauge tracks. Tiannuo delivered exactly what we needed—on time and within budget.”

— Procurement Lead, National Rail Service (India)

“The equipment is sturdy, easy to operate, and our technicians loved how quickly it integrated into our existing machines.”

— Construction Contractor, Infrastructure Project (Canada)

8. FAQ

Q1: Can this machine fit our existing rail-road excavators?

Yes. We support full customization to match your excavator’s specs, including hydraulic flow, rail wheel spacing, and attachment type.

Q2: What’s the typical delivery timeline?

Standard models ship in 10–20 business days. Custom models may take slightly longer, depending on complexity.

Q3: Is on-site installation or training provided?

Yes, we offer remote training support, manuals, and on-site service upon request.

Q4: How often does the equipment require maintenance?

Minimal maintenance is needed. Regular hydraulic checks and lubrication are sufficient for long-term use.

Q5: What certifications do your products meet?

We follow ISO 9001:2015 standards and can meet CE, ROHS, or other regional compliance requirements as needed.

9. Why Tiannuo Is the Right Choice for Your Project

Our Rail-Road Ballast Undercutter Excavator is designed with your business needs in mind:

🎯 For construction companies, we deliver time-saving maintenance solutions that reduce costly track shutdowns.

⛏️ For mining and logistics companies, we offer rugged reliability for remote and heavy-use applications.

🌱 For environmental and public agencies, our equipment supports sustainable rail infrastructure management.

Whether you're working on project-based procurement or planning annual equipment budgets, Tiannuo offers:

- Transparent pricing and fast quotations

- Dedicated after-sales service

- Scalable production for both small and large orders

- Long-term supplier partnership opportunities

Ready to Upgrade Your Rail Maintenance Equipment?

📧 Reach out today for a free consultation or quotation:

YOU MAY LIKE

VIEW MOREExcavator Railway Slope Cleaning Machine

VIEW MOREExcavator Railway Slope Cleaning Machine VIEW MOREExcavator Sleeper Clamp

VIEW MOREExcavator Sleeper Clamp VIEW MOREExcavator Hydraulic Rail Clamp

VIEW MOREExcavator Hydraulic Rail Clamp VIEW MOREDegree Rotating Hydraulic Tilt Ditching Bucket

VIEW MOREDegree Rotating Hydraulic Tilt Ditching Bucket VIEW MOREExcavator ballast cleaning hopper

VIEW MOREExcavator ballast cleaning hopper VIEW MOREExcavator rail clamp

VIEW MOREExcavator rail clamp VIEW MORERail Track Trolley

VIEW MORERail Track Trolley VIEW MORERailway Excavator Cleaning Bucket

VIEW MORERailway Excavator Cleaning Bucket