Can a rotating excavator bucket tilt 45 degrees?

Excavators are powerful machines that have revolutionized the construction and mining industries. One of the most innovative attachments for these versatile machines is the rotating excavator bucket. This advanced tool has significantly enhanced the capabilities of excavators, allowing for more precise and efficient operations. In this article, we'll explore the tilting capabilities of rotating buckets, focusing on whether they can achieve a 45-degree tilt and the advantages this feature brings to excavation work.

How Does a Rotating Excavator Bucket Achieve Tilting Motion?

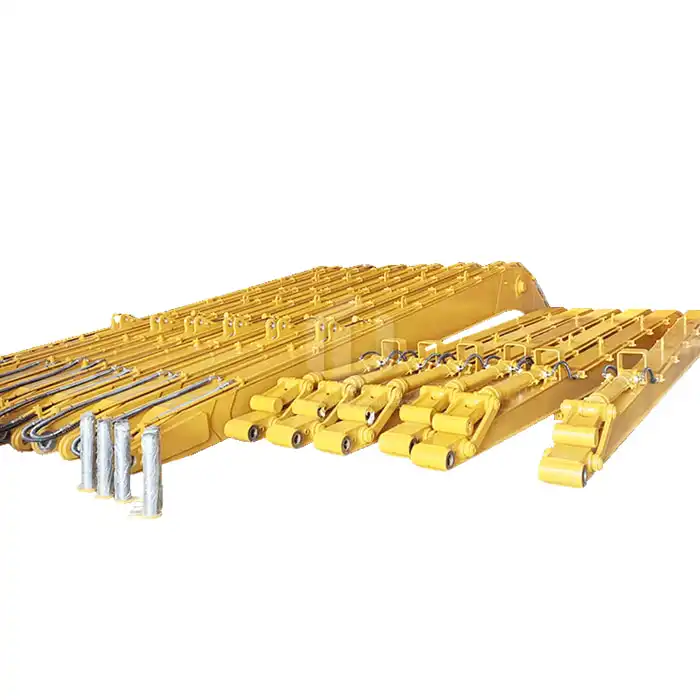

Rotating excavator buckets are engineered to provide enhanced flexibility and maneuverability during excavation tasks. The tilting motion is achieved through a sophisticated hydraulic system that allows the bucket to pivot on its axis. This system typically consists of hydraulic cylinders, rotary actuators, and a series of control valves that work in harmony to provide smooth and precise movements.

The hydraulic system is connected to the excavator's main hydraulic circuit, drawing power from the machine's engine. When the operator activates the tilt function, hydraulic fluid is directed to the appropriate cylinders or actuators, causing the bucket to pivot. The degree of tilt can be finely controlled, allowing for precise adjustments to meet the specific requirements of each task.

Advanced rotating excavator buckets often incorporate sensors and electronic controls that provide feedback to the operator, enabling more accurate positioning and movement. This level of control is particularly beneficial when working in confined spaces or on projects that require high precision, such as grading or landscaping.

Can All Rotating Excavator Buckets Tilt 45 Degrees?

While many rotating excavator buckets are capable of tilting to 45 degrees or more, it's important to note that not all models have this capability. The maximum tilt angle can vary depending on the manufacturer, the specific model, and the intended application of the bucket.

Some rotating buckets are designed with a more limited tilt range, perhaps 30 or 40 degrees, which may be sufficient for certain tasks. Others are engineered to exceed 45 degrees, with some high-end models capable of tilting up to 90 degrees or more. The tilt range is often a balance between functionality, structural integrity, and the hydraulic power available from the host machine.

When selecting a rotating excavator bucket, it's crucial to consider the specific requirements of your projects. For general-purpose excavation and grading, a 45-degree tilt is often more than adequate. However, for specialized applications such as working on steep slopes or in tight urban environments, a bucket with a greater tilt range might be beneficial.

It's also worth noting that the actual usable tilt range may be influenced by factors such as the excavator's arm configuration, the weight of the material being handled, and safety considerations. Always consult the manufacturer's specifications and guidelines to ensure you're using the equipment within its designed parameters.

What Are the Advantages of a 45-Degree Tilt in Excavation Work?

A rotating excavator bucket with a 45-degree tilt capability offers numerous advantages in excavation work, significantly enhancing the efficiency and versatility of the machine. Here are some key benefits:

1. Increased Flexibility: The ability to tilt the bucket up to 45 degrees allows operators to work at various angles without repositioning the entire machine. This flexibility is particularly useful when working on uneven terrain or in confined spaces where maneuverability is limited.

2. Improved Precision: The 45-degree tilt enables more precise control over the excavation process. Operators can easily adjust the bucket angle to achieve the desired grade or slope, resulting in more accurate and consistent results. This precision is especially valuable in projects that require fine grading or contouring.

3. Enhanced Efficiency: With the ability to tilt the bucket, operators can maintain optimal digging angles regardless of the machine's position. This reduces the need for frequent repositioning, saving time and fuel. The increased efficiency can lead to faster project completion and reduced operating costs.

4. Versatility in Applications: A 45-degree tilt expands the range of tasks that can be performed with a single attachment. The same bucket can be used for digging, grading, sloping, and even some specialized tasks like ditch cleaning or landscaping. This versatility reduces the need for multiple attachments, saving time and money.

5. Improved Safety: The ability to tilt the bucket allows operators to maintain better visibility of the work area. This improved line of sight enhances safety on the job site, reducing the risk of accidents or damage to underground utilities.

6. Better Material Handling: The tilting capability allows for more efficient loading and unloading of materials. Operators can adjust the bucket angle to optimize the fill and dump cycles, reducing spillage and increasing productivity.

7. Adaptability to Different Soil Conditions: A 45-degree tilt allows the bucket to adapt to various soil conditions more effectively. Whether dealing with loose sand or compacted clay, the operator can adjust the bucket angle to achieve the best penetration and material retention.

8. Reduced Wear and Tear: By allowing the bucket to work at optimal angles, a 45-degree tilt can reduce stress on the equipment. This can lead to decreased wear and tear on the bucket, teeth, and hydraulic components, potentially extending the life of the equipment and reducing maintenance costs.

9. Enhanced Finishing Capabilities: The precise control offered by a 45-degree tilt is particularly beneficial for finishing work. Operators can achieve smooth, even surfaces with greater ease, whether creating slopes for drainage or preparing foundations for construction.

10. Increased Operator Comfort: The ability to adjust the bucket angle reduces the need for awkward machine positioning. This can lead to improved operator comfort over long work hours, potentially increasing productivity and job satisfaction.

China Rotating Excavator Bucket Suppliers

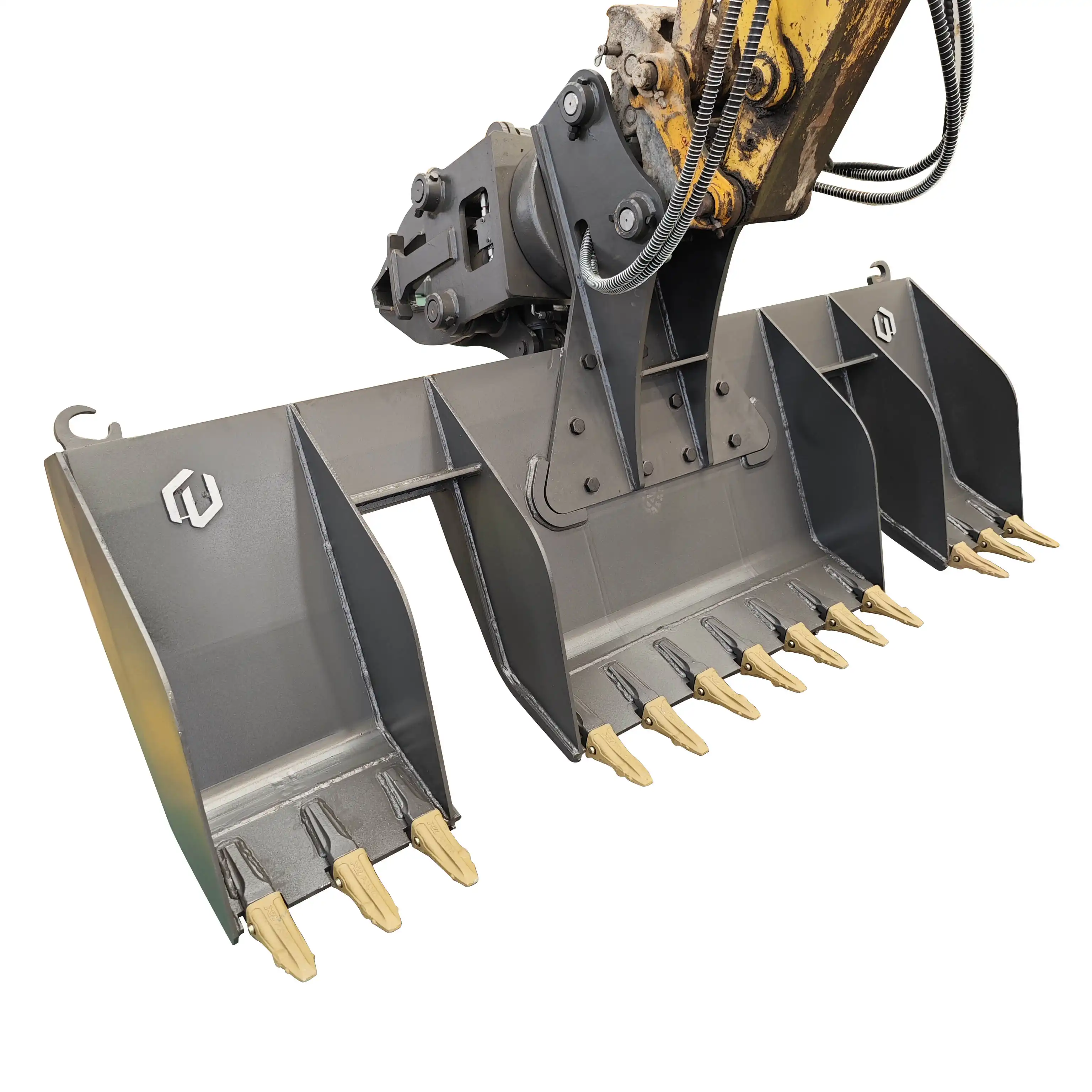

Tiannuo Machinery offers a high-quality degree rotating hydraulic tilt ditching bucket that exemplifies the advantages discussed in this article. With a full 360-degree rotation capability and a 45-degree incline, this bucket provides exceptional versatility and precision for a wide range of excavation tasks. Designed for host machines ranging from 7 to 15 tons and featuring a bucket capacity of 0.4 m³, it's an ideal choice for various construction and earthmoving projects.

If you're in the market for a reliable and efficient degree rotating hydraulic tilt ditching bucket, we invite you to explore what Tiannuo Machinery has to offer. Our team is ready to assist you in finding the perfect solution for your excavation needs. For more information or to discuss your specific requirements, please don't hesitate to contact our manager at arm@stnd-machinery.com. Additionally, our team members are available at rich@stnd-machinery.com and tn@stnd-machinery.com. Let us help you enhance your excavation capabilities with our state-of-the-art rotating excavator buckets.

References

- Haddock, K. (2015). "Modern Earthmoving Machines." Motorbooks International.

- Nichols, H. L., & Day, D. A. (2010). "Moving the Earth: The Workbook of Excavation." McGraw-Hill Professional.

- Peurifoy, R. L., et al. (2018). "Construction Planning, Equipment, and Methods." McGraw-Hill Education.

- Spence, W. P., & Kultermann, E. (2016). "Construction Materials, Methods and Techniques." Cengage Learning.

- Haycraft, W. R. (2011). "Yellow Steel: The Story of the Earthmoving Equipment Industry." University of Illinois Press.

- Nunnally, S. W. (2013). "Construction Methods and Management." Pearson.

- Schaufelberger, J. E., & Migliaccio, G. C. (2019). "Construction Equipment Management." Routledge.