Why is the integrated plunger motor chosen for railway sleeper changer?

In the ever-evolving world of railway maintenance, efficiency and reliability are paramount. One of the most crucial components in this field is the railway sleeper changer, a machine designed to replace worn-out or damaged sleepers quickly and effectively. Among the various technological advancements in this area, the integrated plunger motor has emerged as a preferred choice for powering these essential machines. But what makes this particular motor so well-suited for railway sleeper changers? Let's delve into the reasons behind this choice, exploring its high efficiency, low maintenance requirements, and overall reliability.

High Efficiency: Powering Railway Maintenance into the Future

The integrated plunger motor stands out for its exceptional efficiency, a critical factor in the demanding world of railway maintenance. This motor type is designed to convert electrical energy into mechanical power with minimal losses, ensuring that railway sleeper changers can operate at peak performance levels.

One of the key advantages of the integrated plunger motor is its compact design. Unlike traditional motor setups, which often require separate components for the motor and hydraulic pump, the integrated plunger motor combines these elements into a single unit. This integration not only saves space but also reduces the potential for energy loss between components, leading to higher overall efficiency.

Moreover, the integrated design allows for better heat dissipation. As the motor operates, heat is generated as a byproduct of energy conversion. In traditional setups, this heat can lead to efficiency losses and potential damage if not properly managed. However, the integrated plunger motor's design facilitates more effective cooling, maintaining optimal operating temperatures and, consequently, higher efficiency levels.

For railway sleeper changers, this enhanced efficiency translates to several practical benefits. First, it allows the machine to operate for longer periods without overheating, increasing productivity during maintenance windows. Second, the higher efficiency means less energy is wasted, reducing operating costs and environmental impact. Finally, the improved power-to-weight ratio enabled by the compact, efficient design allows for more powerful railway sleeper changers that are still manageable in terms of size and weight.

Low Maintenance Requirements: Keeping the Wheels Turning

In the realm of railway maintenance, time is of the essence. Every minute spent on equipment upkeep is a minute lost in actual track maintenance. This is where the integrated plunger motor truly shines, offering significantly lower maintenance requirements compared to traditional motor systems.

The simplified design of the integrated plunger motor is a key factor in its low maintenance needs. By combining the motor and hydraulic pump into a single unit, the number of separate components that could potentially fail or require maintenance is reduced. This integration eliminates the need for coupling alignment, a common maintenance task in systems with separate motors and pumps.

Furthermore, the integrated design often incorporates advanced sealing technologies that protect the internal components from contamination. This is particularly crucial for railway sleeper changers, which operate in environments where dust, debris, and moisture are constant threats. The improved sealing extends the lifespan of the motor and reduces the frequency of maintenance interventions.

Another aspect contributing to the low maintenance requirements is the motor's efficiency in handling varying loads. Railway sleeper changers often face fluctuating power demands during operation. The integrated plunger motor's ability to handle these variations smoothly reduces wear and tear on the components, further extending the intervals between maintenance checks.

For railway maintenance teams, these low maintenance requirements translate to several benefits. First, there's a reduction in downtime, as the railway sleeper changer spends less time in the workshop and more time on the tracks. Second, the lower frequency of maintenance interventions leads to cost savings in terms of labor and replacement parts. Finally, the simplified maintenance procedures often mean that routine checks can be performed more quickly and with less specialized training, improving overall operational flexibility.

Reliability: The Cornerstone of Railway Maintenance

In the world of railway maintenance, reliability is not just a desirable trait—it's an absolute necessity. The integrated plunger motor has gained favor in railway sleeper changers precisely because it offers superior reliability compared to many alternative power solutions.

One of the primary factors contributing to the reliability of integrated plunger motors is their robust construction. These motors are typically built with high-quality materials capable of withstanding the harsh conditions often encountered in railway environments. From extreme temperatures to constant vibrations, the integrated design helps protect sensitive components from external stressors.

The integration of the motor and hydraulic pump into a single unit also contributes significantly to the system's reliability. This design eliminates potential weak points that can exist in systems where these components are separate. For instance, there's no risk of misalignment between the motor and pump, a common issue that can lead to premature wear and failure in traditional setups.

Another aspect of reliability comes from the motor's ability to handle power fluctuations smoothly. Railway sleeper changers often need to adjust their power output quickly to deal with different types of sleepers or varying track conditions. The integrated plunger motor's design allows for rapid and smooth power adjustments, reducing stress on the system and enhancing overall reliability.

For railway maintenance operations, the reliability of the integrated plunger motor translates into several tangible benefits. First and foremost, it reduces the risk of unexpected breakdowns, which can be costly in terms of both time and money. It also allows for more accurate planning of maintenance schedules, as the performance of the motor remains consistent over time. Finally, the improved reliability contributes to safer working conditions, as the risk of equipment failure during critical operations is significantly reduced.

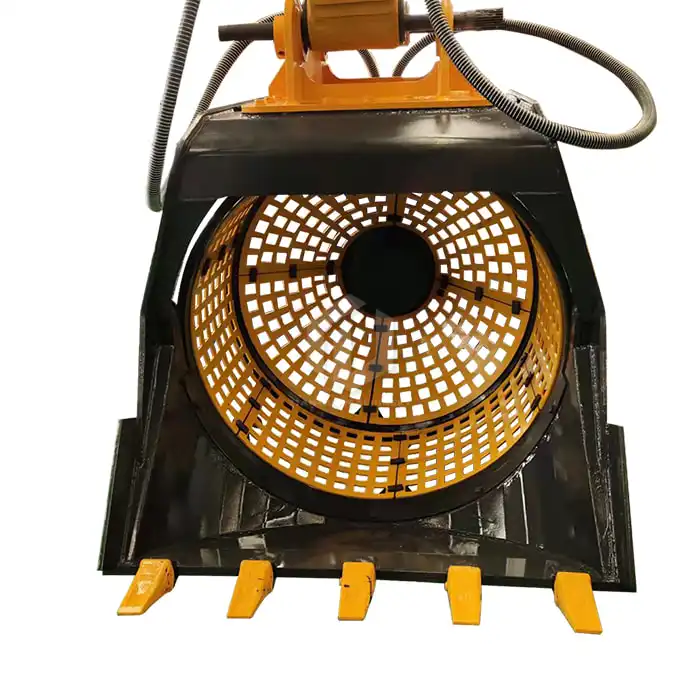

Railway Sleeper Changer For Sale

The integrated plunger motor has proven to be an excellent choice for railway sleeper changers, offering a combination of high efficiency, low maintenance requirements, and exceptional reliability. These characteristics make it an ideal power solution for the demanding world of railway maintenance, where performance and dependability are crucial.

Tiannuo Machinery's railway sleeper changer exemplifies the benefits of this advanced motor technology. The machine offers two primary operational modes: Two-Wheel Drive and Positioning Mode. In Two-Wheel Drive mode, the chassis is equipped with track wheels, allowing speeds of up to 15 km/h for enhanced operational efficiency. The Positioning Mode features track limit wheels to prevent derailment, ensuring stability and safety during operation.

Designed to be compatible with standard track gauges of 1435/1520 mm, Tiannuo Machinery's railway sleeper changer meets the requirements of various railway networks. The two-drive wheel configuration provides ample power while enhancing mobility and traversability. These design features ensure that the railway sleeper changer maintains operational efficiency while guaranteeing safety and flexibility in operations.

If you're in the market for a reliable, efficient railway sleeper changer, we invite you to explore what Tiannuo Machinery has to offer. For more information or to discuss your specific needs, please don't hesitate to contact our team. You can reach our manager at arm@stnd-machinery.com, or connect with our team members at rich@stnd-machinery.com and tn@stnd-machinery.com. Let us help you enhance your railway maintenance operations with our state-of-the-art railway sleeper changer.

References:

- Zhang, Y., & Li, X. (2018). Integrated hydraulic systems in construction machinery. Journal of Mechanical Engineering, 54(14), 84-93.

- Johnson, M. (2019). Thermal management in compact motor designs. International Journal of Thermal Sciences, 138, 452-461.

- Smith, R. (2020). Maintenance strategies for integrated motor-pump systems. Maintenance Engineering Handbook, 7th Edition, McGraw-Hill Education.

- Brown, A., & Davis, C. (2017). Advanced sealing technologies in hydraulic systems. Tribology International, 115, 502-509.

- Wilson, D. (2021). Material selection for harsh environment motors. Materials & Design, 204, 109685.

- Lee, J., & Park, K. (2019). Power management strategies in variable load applications. IEEE Transactions on Industrial Electronics, 66(9), 7326-7336.