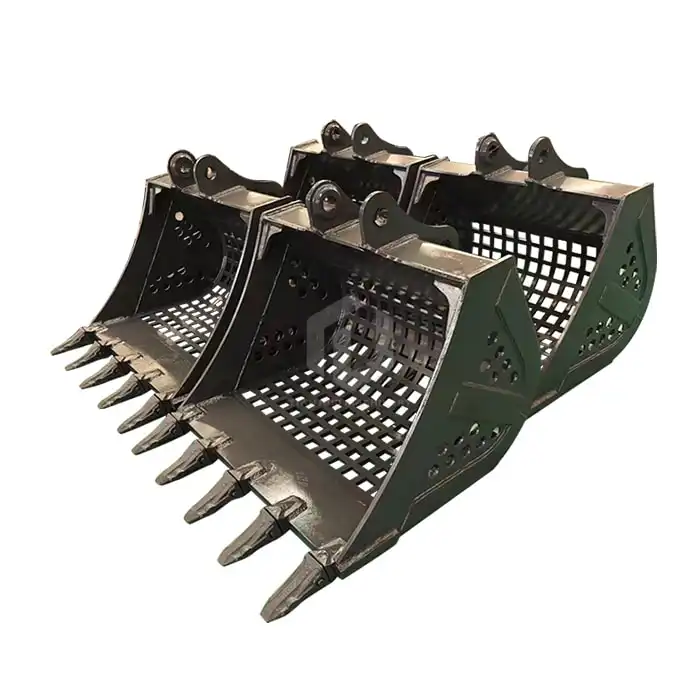

Excavator Screening Bucket

Grid Specifications (mm): 55 x 55

Width (mm): 1000

Height (mm): 620

Depth (mm): 570

Material: Q460 + WH60C

Applicable Working Conditions: Railway ballast screening operations

- Product Description

- Specifications

At Tiannuo Machinery, we specialize in providing high-quality Excavator Screening Buckets designed to meet the demanding needs of the construction, demolition, landscaping, and recycling industries. With over 10 years of experience, we are committed to delivering innovative solutions that enhance efficiency and productivity on job sites.

What is an Excavator Screening Bucket?

The product is a versatile attachment that fits onto excavators, enabling the efficient sorting and separation of materials directly on-site. These buckets are essential for projects that require the precise screening of soil, debris, aggregates, and recyclable materials. By using Excavator Screening Bucket operators can streamline material handling, reduce the need for multiple handling equipment, and improve overall project efficiency.

Excavator Screening Bucket Key Features:

High Durability: Constructed with heavy-duty materials, our buckets are built to withstand the rigors of demanding environments, ensuring long-term use and minimal maintenance.

Versatile Screening Capabilities: Equipped to handle a wide range of materials, including soil, sand, gravel, demolition debris, and more, making them suitable for various applications.

Customizable Options: Our Excavator Screening Bucket can be tailored with adjustable screens to meet specific project requirements, offering flexibility for different material types and sizes.

Efficient Design: Engineered to provide high screening efficiency, reducing downtime and increasing throughput, which translates to cost savings and faster project completion.

Easy Attachment: Designed for quick attachment and detachment from excavators, improving operational efficiency and ease of use.

Benefits of Using Tiannuo Excavator Screening Buckets

Increased Efficiency: By integrating screening capabilities directly into the excavator's workflow, our buckets reduce the need for additional sorting equipment, streamlining the process and saving time.

Cost Savings: Lower transportation costs due to on-site material separation. Less need for off-site processing reduces project expenses.

Enhanced Material Quality: Precision screening ensures that only the required materials are retained, improving the quality of the output and reducing contamination.

Environmental Compliance: Our screening buckets help manage waste more effectively, promoting recycling and reducing the environmental impact of construction and demolition activities.

Versatility: Adaptable to various projects, from landscaping to heavy-duty demolition, making them a valuable asset for contractors.

How It Works

Excavator Screening Bucket is attached to the arm of an excavator, utilizing the machine's hydraulic system for operation. As the excavator moves, the bucket scoops up the material, which is then agitated and screened through interchangeable meshes or screens. This process effectively separates fine material from larger aggregates, allowing for immediate reuse or easy disposal of the screened material. The screening action is controlled by the excavator's operator, ensuring precise and efficient handling.

Workshop Display

At Tiannuo Machinery, our production facilities are equipped with state-of-the-art technology and adhere to strict quality control measures. We ensure each product is manufactured to the highest standards, delivering exceptional performance and durability. Visit our workshop gallery to see our production process and commitment to excellence firsthand.

Testimonials

“Tiannuo’s productions have transformed our material handling process. The efficiency and precision of these buckets are unparalleled, reducing our project completion times and costs.” – John D., Construction Project Manager

“We’ve been using Tiannuo’s screening buckets for our demolition projects, and they have made a significant difference in separating materials efficiently. Highly recommend!” – Lisa M., Demolition Contractor

FAQ

Q1: Can the product handle different types of materials?

A: Yes, Tiannuo Excavator Screening Buckets are designed to handle a variety of materials, including soil, gravel, sand, demolition debris, and recyclable materials.

Q2: Are there customization options available for the screening bucket?

A: Absolutely. We offer customizable options, including adjustable screens to accommodate different material types and sizes, ensuring the bucket meets your specific project needs.

Q3: What maintenance is required for these buckets?

A: Regular inspection and cleaning of the screening bucket will help maintain its performance. Our buckets are designed for durability, requiring minimal maintenance under normal operating conditions.

Q4: Do you provide after-sales support?

A: Yes, Tiannuo Machinery offers comprehensive after-sales support, including training, maintenance services, and easy access to replacement parts.

Q5: What excavator sizes are compatible with your screening buckets?

A: Our screening buckets are compatible with excavators ranging from 10 to 40 tons, providing flexibility for different project requirements.

Contact Us

Ready to enhance your material handling efficiency with our products? Contact us today at rich@stnd-machinery.com or arm@stnd-machinery.com to learn more about our products and services. Our team of experts is here to provide you with the best solutions tailored to your specific needs.

| Dourong (M3) | 0.4 (customizable) |

| Grid specification (mm) | 55*55 |

| Width (mm) | 1000 |

| Height (mm) | 620 |

| Depth (mm) | 570 |

| material quality | Q460+WH60C |

| Applicable working conditions | Railway ballast screening operation |

YOU MAY LIKE

VIEW MORERailway Sleeper Changer

VIEW MORERailway Sleeper Changer VIEW MOREBallast Blaster Undercutter

VIEW MOREBallast Blaster Undercutter VIEW MOREExcavator Railway Slope Cleaning Machine

VIEW MOREExcavator Railway Slope Cleaning Machine VIEW MOREHigh-vibration hydraulic ballast tamping machine

VIEW MOREHigh-vibration hydraulic ballast tamping machine VIEW MOREExcavator rock single hook

VIEW MOREExcavator rock single hook VIEW MOREExcavator Sleeper Clamp

VIEW MOREExcavator Sleeper Clamp VIEW MOREBallast Plow

VIEW MOREBallast Plow VIEW MORERailway Excavator Ballast Plow

VIEW MORERailway Excavator Ballast Plow