Why can an excavator ripper effectively separate soil and rocks?

Excavator rippers have become an indispensable tool in construction and mining industries, known for their remarkable ability to effectively separate soil and rocks. These powerful attachments have revolutionized the way we approach challenging terrains and hard soil conditions. But what makes an excavator ripper so effective at this crucial task? In this comprehensive guide, we'll delve into the key factors that contribute to its efficiency in separating soil and rocks, exploring its specialized design, hydraulic force, and high breaking force.

Specialized Design

The effectiveness of an excavator ripper in separating soil and rocks lies primarily in its specialized design. Engineers have meticulously crafted these attachments to optimize their performance in various soil conditions and rock types. its design takes into account several crucial factors that contribute to its efficiency:

1. Tooth Configuration: The ripper tooth, often made of high-strength steel, is designed with a specific shape and angle to penetrate soil and rock effectively. The tooth's pointed tip concentrates force into a small area, allowing it to break through even the toughest materials. Some rippers feature multiple teeth, increasing the contact area and improving overall performance.

2. Shank Design: The shank, which connects the tooth to the ripper body, is engineered to withstand immense stress and transfer the excavator's power efficiently. Its curved design helps in lifting and separating material as the ripper moves through the ground.

3. Adaptability: Many modern excavator rippers are designed with interchangeable teeth or adjustable shanks. This adaptability allows operators to customize the ripper for specific soil conditions or rock types, enhancing its effectiveness across various job sites.

4. Material Selection: The choice of materials used in constructing the ripper is crucial. High-grade, wear-resistant steels are typically used to ensure durability and maintain performance even under extreme conditions.

5. Size and Weight: they are available in various sizes and weights to match different excavator models. This ensures optimal balance and leverage, allowing the excavator to apply maximum force efficiently.

The specialized design of excavator rippers is the result of years of engineering refinement and field testing. It's this thoughtful design that allows these attachments to effectively penetrate, lift, and separate soil and rocks with remarkable efficiency.

Hydraulic Force

The power behind an excavator ripper's ability to separate soil and rocks comes from its hydraulic system. This sophisticated system harnesses the excavator's engine power and converts it into the immense force needed to break through tough materials. Here's how hydraulic force contributes to the ripper's effectiveness:

1. Power Transmission: The hydraulic system efficiently transmits power from the excavator's engine to the ripper attachment. This allows for the application of tremendous force at the ripper's tip, enabling it to penetrate even the hardest soil and rock formations.

2. Precise Control: Hydraulic systems offer operators fine control over the ripper's movement and applied force. This precision is crucial when working in areas with varying soil conditions or when trying to avoid damaging underground utilities.

3. Consistent Performance: Unlike mechanical systems that may lose efficiency over time, hydraulic systems maintain consistent performance. This ensures that the ripper can operate at peak efficiency throughout long work shifts.

4. Adaptability to Conditions: The hydraulic system allows the ripper to adapt to different soil conditions quickly. Operators can adjust the hydraulic pressure to increase or decrease the force applied, depending on the material being worked on.

5. Energy Efficiency: Modern hydraulic systems are designed to be energy-efficient, maximizing the power output while minimizing fuel consumption. This not only improves the ripper's performance but also contributes to more sustainable operations.

The hydraulic force behind excavator rippers is a key factor in their ability to effectively separate soil and rocks. It provides the necessary power and control to tackle even the most challenging terrains, making these attachments indispensable in various construction and mining operations.

High Breaking Force

The high breaking force of an excavator ripper is perhaps its most impressive feature when it comes to separating soil and rocks. This formidable force is what allows the ripper to break through extremely hard materials that would be impossible to handle with conventional digging methods. Let's explore how this high breaking force contributes to the ripper's effectiveness:

1. Concentrated Force Application: The ripper's design allows it to concentrate an enormous amount of force into a small area at its tip. This concentrated force can exceed the compressive strength of many types of rock, causing them to fracture and break apart.

2. Leveraging Excavator Weight: The ripper's high breaking force is not just a result of hydraulic power, but also leverages the weight of the excavator itself. As the excavator pushes or pulls the ripper, its entire weight contributes to the breaking force, significantly enhancing its effectiveness.

3. Penetration and Lifting Action: The high breaking force allows the ripper to not only penetrate hard soil and rock but also lift and separate the material. This combined action is crucial for effectively breaking up and removing tough materials.

4. Overcoming Material Cohesion: In many cases, the strength of soil or rock comes from the cohesion between particles. The high breaking force of an excavator ripper is capable of overcoming this cohesion, effectively separating the material.

5. Adaptability to Material Strength: The breaking force can often be adjusted to match the strength of the material being worked on. This adaptability ensures efficient operation across various soil and rock types without unnecessary wear on the equipment.

6. Consistent Performance: Unlike impact-based breaking methods, the steady application of high force by a ripper provides consistent performance. This is particularly beneficial when working with materials of varying hardness or in situations where vibration needs to be minimized.

The high breaking force of an excavator ripper is a testament to modern engineering and design. It's this force that allows these attachments to tackle jobs that would be impossible or extremely time-consuming with other methods, making them an invaluable tool in construction and mining operations.

Excavator Ripper For Sale

The excavator ripper's ability to effectively separate soil and rocks is a result of its specialized design, powerful hydraulic force, and high breaking force. These factors work in harmony to create a tool that can tackle even the most challenging terrains with ease and efficiency.

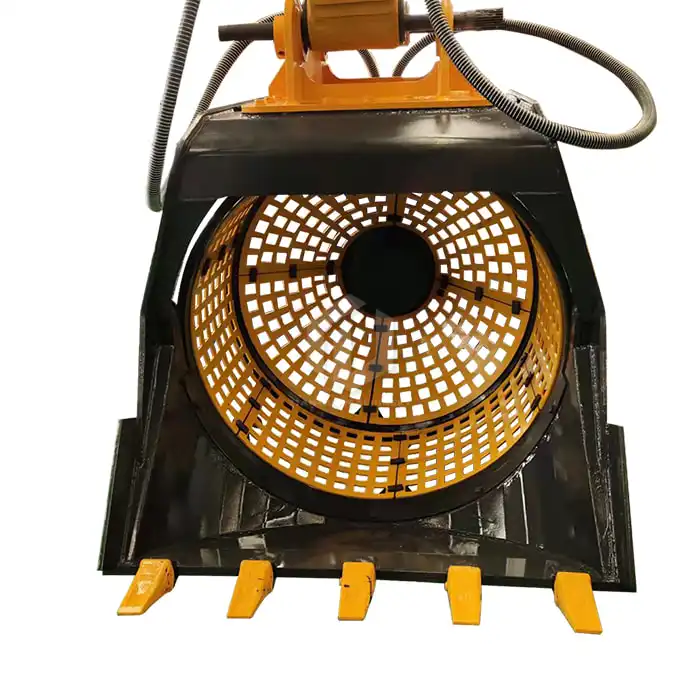

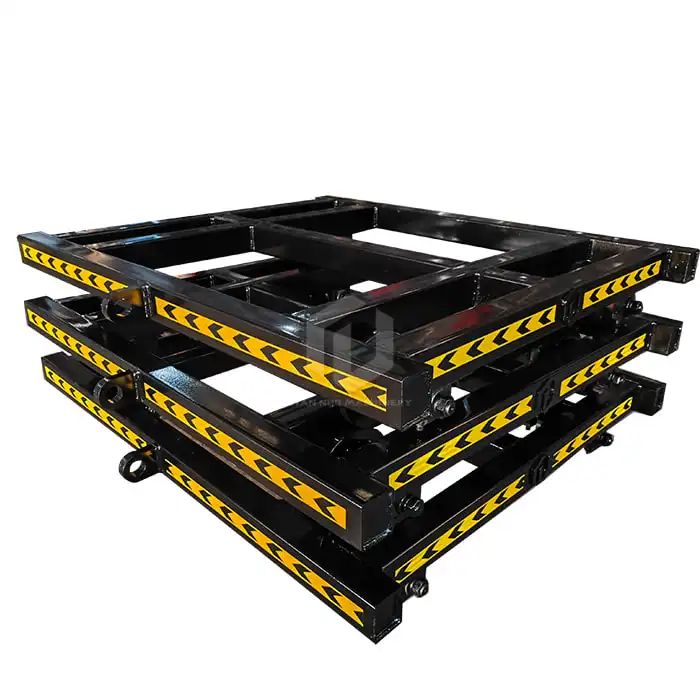

Tiannuo Machinery's excavator ripper exemplifies these qualities, boasting strong digging and cutting abilities that make it convenient for loosening sections and easily separating soil and rock to reduce cutting resistance. Its design allows for easy disassembly and replacement, prolonging its lifespan and ensuring consistent performance over time.

Technically, Tiannuo's rippers are designed for various working weights and material strengths. They offer rippers for machines ranging from 3-5T to 31-35T, with varying board thicknesses and materials to meet different operational needs. This range of options ensures that you can find the perfect ripper for your specific requirements, regardless of the scale or nature of your project.

If you're in the market for a high-quality excavator ripper that embodies these crucial characteristics, we invite you to explore what Tiannuo Machinery has to offer. Our team of experts is ready to assist you in finding the perfect ripper for your needs. For more information or to discuss your requirements, please don't hesitate to reach out to our manager at arm@stnd-machinery.com, or contact our team members at rich@stnd-machinery.com and tn@stnd-machinery.com. Let Tiannuo Machinery be your partner in enhancing your excavation capabilities and productivity.

References:

- Caterpillar Inc. (2019). Excavator Attachments Guide.

- Komatsu Ltd. (2020). Hydraulic Excavator Handbook.

- Construction Equipment Magazine. (2018). Trends in Excavator Attachment Design.

- Journal of Construction Engineering. (2021). Material Innovations in Excavation Equipment.

- Heavy Equipment Guide. (2020). Choosing the Right Excavator Ripper.

- Hydraulics & Pneumatics. (2019). Hydraulic Systems in Modern Excavators.