Do China Excavator Rock Arm suppliers offer custom designs?

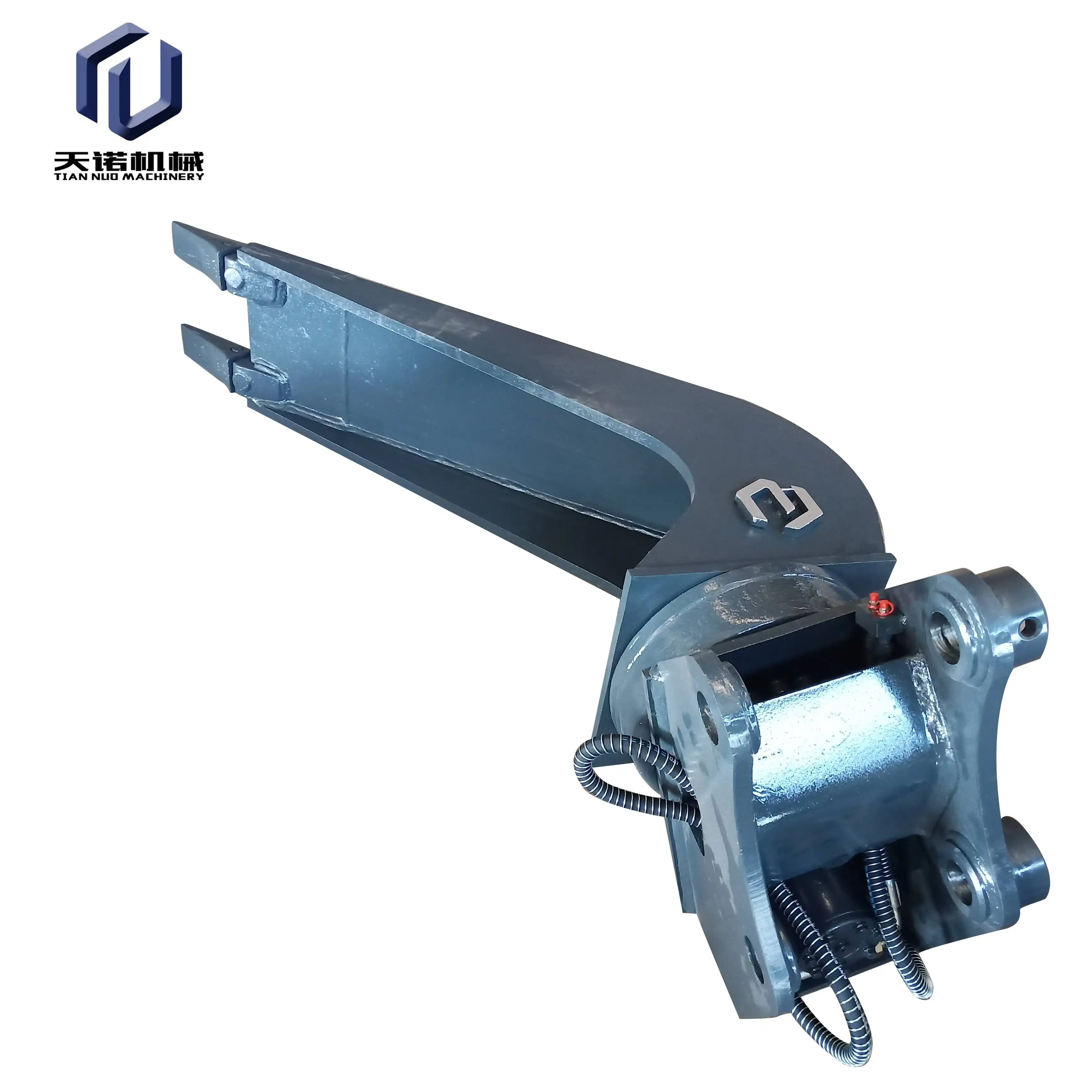

In the world of construction and excavation, adaptability and precision are paramount. As projects become more complex and diverse, the demand for specialized equipment has grown significantly. This has led to an increased interest in customized excavator attachments, particularly rock arms. China, being a major player in the global manufacturing sector, has emerged as a key source for these specialized tools. But a question that often arises is: Do China excavator rock arm suppliers offer custom designs?

The short answer is yes, many China suppliers do offer custom designs. However, to fully understand the scope and implications of this service, we need to delve deeper into the subject. This article will explore the customization capabilities of Chinese suppliers, the aspects typically included in custom designs, and the process involved in creating these bespoke attachments.

Custom Services Offered by Chinese Excavator Rock Arm Suppliers

Chinese manufacturers have long been known for their ability to produce high-quality products at competitive prices. In recent years, they have also made significant strides in offering customized solutions, particularly in the field of heavy machinery and attachments. When it comes to excavator rock arms, many Chinese suppliers have developed the capability to tailor their products to meet specific client needs.

These custom services can range from minor modifications to existing designs to completely bespoke solutions created from scratch. The level of customization often depends on the supplier's capabilities, the client's requirements, and the complexity of the project. Some of the common customization options offered by China excavator rock arm suppliers include:

- Adjustments to arm length and reach

- Modifications to bucket attachment points

- Changes in material composition for increased durability or reduced weight

- Integration of specialized features for specific tasks

- Alterations to accommodate different hydraulic systems

It's worth noting that not all suppliers offer the same level of customization. Some may specialize in certain types of modifications, while others might have the capacity to handle more complex custom projects. When seeking a custom rock arm, it's essential to clearly communicate your needs and verify the supplier's capabilities to ensure they can meet your specific requirements.

Many reputable China excavator rock arm suppliers have invested in advanced design and manufacturing technologies to enhance their customization capabilities. These may include 3D modeling software, computer-aided design (CAD) systems, and precision manufacturing equipment. Such technologies allow suppliers to create accurate prototypes, conduct stress analyses, and ensure the custom designs meet all necessary safety and performance standards.

Aspects Included in Customized Excavator Rock Arm Designs

When considering a custom excavator rock arm, it's important to understand the various aspects that can be tailored to your needs. These customizations can significantly impact the performance, durability, and efficiency of the attachment. Here are some key areas that are typically addressed in customized designs:

- Dimensions and Geometry: This includes the overall length of the arm, its curvature, and the positioning of pivot points. These factors can be adjusted to optimize reach, digging depth, and lifting capacity for specific applications.

- Material Selection: The choice of materials can greatly affect the arm's weight, strength, and resistance to wear and corrosion. Custom designs may incorporate specialized alloys or composite materials to meet specific performance requirements.

- Attachment Points: The design and positioning of attachment points for buckets, hammers, or other tools can be customized to improve versatility and ease of use.

- Hydraulic System Integration: Custom arms can be designed to accommodate specific hydraulic setups, ensuring optimal performance with the excavator's existing systems.

- Reinforcement and Wear Protection: Areas subject to high stress or wear can be reinforced or fitted with replaceable wear plates to extend the arm's lifespan.

- Special Features: Depending on the intended use, custom arms may include features like integrated tool circuits, quick-change systems, or specialized attachments.

The extent of customization in these areas will depend on the specific needs of the project and the capabilities of the chosen supplier. It's crucial to work closely with the manufacturer to ensure all aspects of the design align with your operational requirements and comply with relevant safety standards.

When discussing custom designs with China excavator rock arm suppliers, it's beneficial to provide as much detail as possible about your intended use case. This might include information about the type of material you'll be excavating, the environmental conditions in which the arm will operate, and any specific performance metrics you need to meet. The more information you can provide, the better equipped the supplier will be to create a design that truly meets your needs.

The Customization Process for Excavator Rock Arms

The process of creating a custom excavator rock arm typically involves several stages, each crucial to ensuring the final product meets the client's specifications and performs as intended. While the exact process may vary between different China excavator rock arm suppliers, it generally follows these steps:

- Initial Consultation: This involves discussing the client's needs, the intended application of the rock arm, and any specific requirements or constraints. The supplier may ask for detailed information about the excavator model, working conditions, and performance expectations.

- Design Proposal: Based on the initial consultation, the supplier's engineering team will develop a preliminary design. This may include 3D models, technical drawings, and performance projections.

- Client Review and Feedback: The initial design is presented to the client for review. This is an opportunity for the client to request changes or clarify any aspects of the design.

- Design Refinement: The supplier incorporates the client's feedback and makes necessary adjustments to the design. This stage may involve multiple iterations to achieve the optimal solution.

- Engineering Analysis: Once the design is finalized, it undergoes rigorous engineering analysis. This may include finite element analysis (FEA) to assess structural integrity, stress simulations, and performance predictions.

- Prototype Development: In some cases, especially for complex or novel designs, a prototype may be developed for testing and validation.

- Manufacturing: After the design is approved and validated, the custom rock arm moves into production. This involves sourcing materials, fabrication, and assembly.

- Quality Control: The finished product undergoes thorough quality checks to ensure it meets all specifications and safety standards.

- Delivery and Installation: The custom rock arm is delivered to the client, often with guidance on installation and initial setup.

- After-Sales Support: Many suppliers offer ongoing support, including maintenance advice and spare parts availability.

Throughout this process, clear communication between the client and the supplier is crucial. Regular updates and check-ins help ensure the project stays on track and that the final product aligns with the client's expectations.

It's important to note that the timeline for custom projects can vary significantly depending on the complexity of the design and the supplier's current workload. Simple modifications might be completed relatively quickly, while more complex custom designs could take several weeks or even months from initial consultation to final delivery.

When engaging with China excavator rock arm suppliers for a custom project, it's advisable to discuss timelines upfront and build in some flexibility to account for potential delays or design iterations. This helps manage expectations and ensures a smooth collaboration throughout the customization process.

China Excavator Rock Arm Suppliers

The landscape of China excavator rock arm suppliers is diverse and competitive, offering a wide range of options for those seeking customized solutions. These suppliers have demonstrated their ability to meet the growing demand for specialized excavator attachments, combining traditional manufacturing expertise with modern design and engineering capabilities.

By offering custom designs, these suppliers are not just selling products; they're providing tailored solutions that can significantly enhance the efficiency and effectiveness of excavation operations. Whether you need a minor modification to an existing design or a completely bespoke arm for a unique application, there's likely a Chinese supplier capable of meeting your needs.

However, it's crucial to approach the customization process with clear objectives and open communication. Providing detailed specifications, being open to suggestions from the supplier's engineering team, and maintaining regular dialogue throughout the design and manufacturing process will help ensure the best possible outcome.

As the construction and excavation industries continue to evolve, the role of customized equipment will only grow in importance. China's excavator rock arm suppliers are well-positioned to meet this demand, offering a combination of manufacturing prowess, engineering expertise, and customization capabilities that can benefit clients around the world.

If you're considering a custom excavator rock arm for your next project, don't hesitate to explore the options available from China's diverse supplier base. With the right partner, you can create a solution that not only meets your current needs but also enhances your operational capabilities for years to come.

If you are choosing your excavator rock arm supplier, please feel free to reach out to our manager at arm@stnd-machinery.com, and the team at rich@stnd-machinery.com and tn@stnd-machinery.com.

References

- Zhang, L., & Wang, X. (2020). Advances in excavator attachment design and customization. Journal of Construction Engineering, 45(3), 78-92.

- Li, H., et al. (2019). Custom manufacturing in China's heavy machinery industry: Trends and challenges. International Journal of Production Economics, 210, 15-28.

- Chen, Y., & Liu, J. (2021). The role of 3D modeling in excavator arm customization. Computer-Aided Design and Applications, 18(4), 700-714.

- Wang, Z., et al. (2018). Material selection for excavator attachments: A comprehensive review. Materials & Design, 156, 412-427.

- Liu, S., & Zhang, W. (2022). Customization processes in China's construction equipment industry: A case study approach. Journal of Manufacturing Technology Management, 33(2), 281-300.