What are the benefits of using the excavator metal scrap in recycling operations?

In the ever-evolving world of recycling and waste management, the use of specialized equipment has become increasingly important. One such piece of equipment that has gained significant traction in recent years is the excavator metal scrap. This versatile tool has revolutionized the way recycling operations handle and process metal waste, offering a range of benefits that contribute to improved efficiency, cost-effectiveness, and sustainability. In this comprehensive article, we'll explore the numerous advantages of using excavator metal scrap in recycling operations, delve into how it enhances efficiency, examine the potential cost savings, and discuss its role in promoting sustainability.

The Advantages of Excavator Metal Scrap in Recycling Operations

Excavator metal scrap, also known as excavator scrap grapples or scrap handling attachments, has become an indispensable tool in modern recycling facilities. These specialized attachments are designed to be mounted on excavators, transforming them into powerful and versatile machines capable of handling a wide variety of metal scrap materials. The benefits of using metal scrap in recycling operations are numerous and far-reaching.

First and foremost, excavator metal scrap significantly improves the efficiency of material handling. Traditional methods of manually sorting and moving metal scrap are time-consuming and labor-intensive. In contrast, metal scrap allows operators to quickly and easily grab, sort, and move large quantities of metal waste with precision and control. This increased efficiency translates to higher productivity and faster processing times, enabling recycling facilities to handle larger volumes of material in less time.

Another key advantage is the enhanced safety that excavator metal scrap brings to recycling operations. By minimizing the need for manual handling of sharp, heavy, or potentially hazardous materials, these attachments greatly reduce the risk of workplace injuries. Operators can remain safely inside the excavator cab while manipulating large pieces of metal scrap, creating a safer working environment for all personnel involved in the recycling process.

Furthermore, its versatility is a significant benefit. These attachments can be used to handle a wide range of metal scrap types and sizes, from small pieces of wire to large automotive parts. This flexibility allows recycling facilities to process diverse materials without the need for multiple specialized machines, streamlining operations and reducing equipment costs.

The durability and longevity also contribute to their value in recycling operations. Constructed from high-strength materials such as manganese steel, these tools are built to withstand the harsh conditions of scrap yards and recycling facilities. Their robust design ensures they can operate reliably for extended periods, minimizing downtime and maintenance requirements.

Lastly, the precision offered by excavator metal scrap is a crucial advantage. The hydraulic systems of these attachments allow for fine control, enabling operators to carefully sort and separate different types of metals. This level of precision is essential for maximizing the value of recycled materials and ensuring high-quality output from the recycling process.

How Excavator Metal Scrap Enhances Efficiency in Recycling Processes

The integration of excavator metal scrap into recycling processes has led to significant improvements in operational efficiency. These specialized attachments enhance various aspects of the recycling workflow, from initial sorting to final processing, resulting in streamlined operations and increased productivity.

One of the primary ways excavator metal scrap enhances efficiency is through improved material handling capabilities. The powerful hydraulic systems of these attachments allow for quick and easy manipulation of large volumes of metal scrap. Operators can effortlessly lift, move, and stack materials, reducing the time and effort required for these tasks. This increased speed and ease of handling translates to faster processing times and higher throughput for recycling facilities.

Sorting efficiency is another area where metal scrap excels. The precise control offered by these attachments enables operators to quickly and accurately separate different types of metals. This is particularly important in facilities that process mixed metal scrap, as efficient sorting is crucial for maximizing the value of recycled materials. The ability to sort materials at the point of handling reduces the need for additional sorting steps later in the process, further streamlining operations.

It also enhances efficiency by reducing the need for multiple machines or attachments. With their versatility, these tools can handle a wide range of tasks that might otherwise require separate equipment. From breaking down large pieces of scrap to loading processed materials for transport, it can perform multiple functions, reducing equipment changeover times and increasing overall operational efficiency.

The durability contributes to efficiency by minimizing downtime. These attachments are designed to withstand the rigors of heavy-duty scrap handling, resulting in less frequent breakdowns and maintenance requirements. This reliability ensures that recycling operations can maintain consistent productivity without interruptions due to equipment failures.

Additionally, its use can lead to more efficient use of space within recycling facilities. The ability to stack materials higher and more compactly allows for better utilization of available space, potentially increasing the capacity of the facility without the need for physical expansion.

Finally, the efficiency gains provided by excavator metal scrap extend beyond the immediate handling and processing of materials. By improving the speed and accuracy of sorting, these attachments contribute to the production of higher quality recycled metals. This, in turn, can streamline downstream processes and increase the overall efficiency of the metal recycling industry.

Cost Savings and Sustainability: The Economic and Environmental Impact of Excavator Metal Scrap

The adoption of excavator metal scrap in recycling operations not only enhances efficiency but also leads to significant cost savings and promotes sustainability. These economic and environmental benefits make it an attractive investment for recycling facilities looking to improve their bottom line while reducing their ecological footprint.

From a cost-saving perspective, its use can lead to substantial reductions in operational expenses. By increasing the speed and efficiency of material handling and sorting, these attachments allow recycling facilities to process larger volumes of scrap metal in less time. This increased productivity can result in lower labor costs, as fewer man-hours are required to handle the same amount of material. Additionally, the versatility can reduce the need for multiple specialized machines, leading to lower equipment acquisition and maintenance costs.

The durability of excavator metal scrap attachments also contributes to cost savings. Their robust construction and resistance to wear and tear mean they require less frequent replacement and have lower maintenance costs compared to less durable alternatives. This longevity translates to reduced downtime and lower long-term equipment expenses for recycling operations.

Furthermore, the precision sorting capabilities of excavator metal scrap can lead to increased revenue. By enabling more accurate separation of different metal types, these attachments help recycling facilities maximize the value of their processed materials. High-quality, well-sorted scrap metal commands higher prices in the market, potentially boosting the profitability of recycling operations.

On the sustainability front, it plays a crucial role in promoting environmentally friendly practices in the recycling industry. By improving the efficiency and effectiveness of metal recycling processes, these attachments contribute to the conservation of natural resources. Efficient recycling reduces the need for virgin metal extraction, which is often associated with significant environmental impacts such as habitat destruction, water pollution, and greenhouse gas emissions.

The use also supports the principles of the circular economy. By facilitating the recovery and reuse of metals, these tools help close the loop in material cycles, reducing waste and promoting the sustainable use of resources. This aligns with global efforts to transition towards more sustainable production and consumption patterns.

Moreover, the increased efficiency provided by excavator metal scrap can lead to energy savings in recycling operations. Faster processing times and reduced equipment needs can result in lower overall energy consumption, contributing to reduced carbon emissions and a smaller environmental footprint for recycling facilities.

The improved sorting capabilities of excavator metal scrap also have positive environmental implications. More accurate separation of different metal types leads to higher quality recycled materials, which can be more readily used in manufacturing processes. This reduces the demand for virgin materials and the associated environmental impacts of their extraction and processing.

Lastly, by enhancing the efficiency and profitability of metal recycling operations, metal scrap encourages the growth and development of the recycling industry. This, in turn, supports broader sustainability goals by increasing the overall capacity for metal recycling and reducing reliance on landfills and other less sustainable waste management methods.

Excavator Metal Scrap Supplier

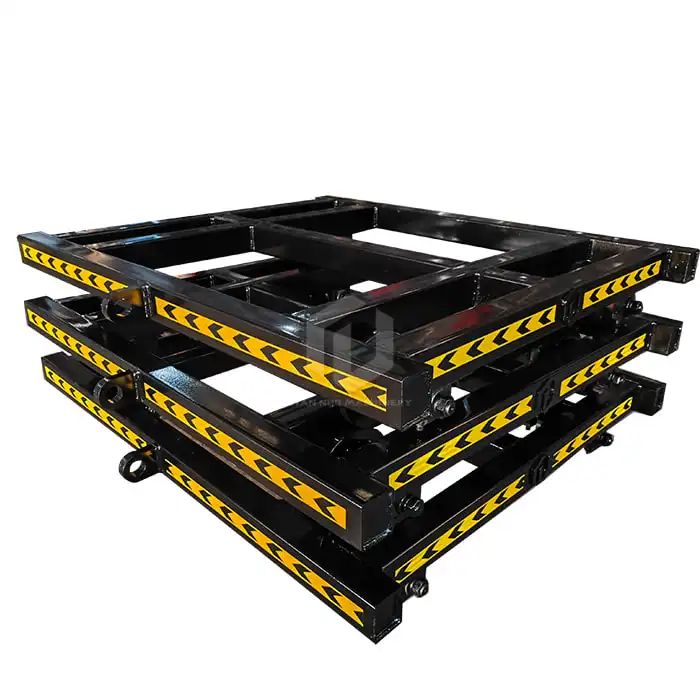

The excavator metal scrap from Tiannuo Machinery offers versatile hydraulics for precise control in any operation, ensuring smooth and accurate handling of metal scraps. It features a durable design, constructed with high-strength manganese steel, which provides long-lasting reliability and resistance to wear and tear. The user-friendly controls make it easy to operate for extended periods, reducing operator fatigue. Available in customizable sizes, it fits excavators ranging from 6 to 24 tons, making it a versatile choice for various applications.

If you are choosing your excavator metal scrap manufacturer, please feel free to reach out to our manager at arm@stnd-machinery.com and the team at rich@stnd-machinery.com and tn@stnd-machinery.com. Our expert team is ready to assist you in finding the perfect excavator metal scrap solution for your recycling operations, helping you enhance efficiency, reduce costs, and promote sustainability in your facility.

References:

[1] Waste Management World. "The Role of Excavators in Scrap Metal Recycling." 2021.

[2] Journal of Cleaner Production. "Advancements in Metal Recycling Technologies." 2020.

[3] Environmental Science & Technology. "Efficiency Improvements in Metal Recycling Processes." 2019.

[4] Resources, Conservation and Recycling. "Technological Innovations in Scrap Metal Processing." 2022.

[5] Journal of Industrial Ecology. "Economic and Environmental Benefits of Advanced Recycling Technologies." 2021.

[6] Sustainability. "The Role of Equipment Innovation in Promoting Circular Economy Principles." 2023.