What are excavator wood clamps used for?

Excavator wood clamps are versatile attachments that have revolutionized the way we handle timber and wood products in various industries. These innovative tools, designed to be fitted onto excavators, provide a secure grip on logs, tree trunks, and other wooden materials, making them indispensable in forestry, logging, wood processing, and landscaping operations. In this comprehensive guide, we'll explore the diverse applications of excavator wood clamps and how they've become essential equipment in multiple sectors.

Forestry and Logging

In the realm of forestry and logging, excavator wood clamps have become indispensable tools that significantly enhance efficiency and safety. These robust attachments are designed to securely grasp and manipulate logs of various sizes, streamlining the entire logging process from felling to transportation.

One of the primary uses of forestry is during the harvesting phase. After trees are felled, these clamps can easily grip and lift logs, allowing for quick and precise positioning. This capability is particularly useful when sorting logs by size or species, a crucial step in many logging operations. The strong grip provided by the clamps ensures that even large, heavy logs can be moved safely, reducing the risk of accidents and improving overall workplace safety.

In addition to harvesting, excavator wood clamps play a vital role in log loading and unloading processes. They can efficiently transfer logs from the forest floor onto waiting trucks or trailers, significantly reducing the time and labor required for this task. The precise control offered by excavator-mounted clamps allows operators to stack logs neatly and securely, maximizing the load capacity of transport vehicles and ensuring safe transportation.

Excavator wood clamps are also invaluable in land clearing operations, particularly when dealing with fallen trees or stumps. The clamps can grip and remove these obstacles with ease, facilitating faster and more efficient land preparation for various purposes, including agriculture, construction, or reforestation efforts.

Moreover, these attachments have proven to be extremely useful in sustainable forestry practices. They allow for selective harvesting, where specific trees can be removed without causing extensive damage to the surrounding vegetation. This precision contributes to better forest management and conservation efforts, aligning with modern sustainable forestry principles.

The versatility extends to other forestry-related tasks as well. They can be used for brush clearing, assisting in the removal of smaller trees and undergrowth. In forest fire prevention efforts, these clamps can help create firebreaks by efficiently removing potential fuel sources.

Overall, the introduction of excavator wood clamps in forestry and logging has led to significant improvements in productivity, safety, and environmental stewardship. As the industry continues to evolve, these attachments are likely to play an even more crucial role in sustainable and efficient forest management practices.

Lumber Mills and Wood Processing Facilities

In lumber mills and wood processing facilities, excavator wood clamps have become integral tools that significantly enhance operational efficiency and material handling capabilities. These robust attachments transform excavators into versatile machines capable of performing a wide range of tasks crucial to the wood processing industry.

One of the primary applications of excavator wood clamps in these facilities is in the initial stages of log processing. As raw logs arrive at the mill, these clamps can efficiently unload them from trucks and transport them to sorting areas. The precise control offered by the excavator allows for careful handling of the logs, minimizing damage and ensuring that each log is placed exactly where it needs to be for further processing.

During the sorting process, wood clamps prove invaluable. They can easily pick up and move logs of various sizes, allowing for quick and accurate sorting based on species, quality, or intended use. This efficiency in sorting contributes significantly to the overall productivity of the mill, ensuring that the right logs are directed to the appropriate processing lines.

In the production area, these clamps assist in feeding logs into various processing equipment such as debarkers, sawmills, and chippers. The ability to precisely position logs ensures smooth operation of these machines, reducing downtime and improving output. For larger logs that require special handling, wood clamps provide the necessary strength and control to maneuver them safely and efficiently.

Waste management is another area where excavator wood clamps excel in wood processing facilities. They can efficiently handle and transport wood waste, such as bark, sawdust, and offcuts, to designated areas for disposal or further processing. This capability not only keeps the work area clean and safe but also facilitates the implementation of waste-to-energy initiatives that many modern mills are adopting.

In lumber yards, these clamps are used for stacking and unstacking processed lumber. Their ability to handle multiple boards at once speeds up the process of creating neat, stable stacks of finished products. When it comes time to load finished lumber onto trucks for distribution, excavator wood clamps can perform this task quickly and efficiently, ensuring that products are loaded securely for transport.

The versatility also extends to maintenance operations within the facility. They can be used to move heavy equipment parts during repairs or replacements, adding an extra layer of utility to the excavator beyond its primary wood-handling duties.

Furthermore, as the wood processing industry moves towards more automated and integrated systems, wood clamps are being incorporated into sophisticated material handling solutions. Some facilities are using excavators equipped with these clamps in conjunction with automated sorting systems and conveyor belts, creating a seamless flow of materials through the entire processing chain.

The adoption of lumber mills and wood processing facilities has led to significant improvements in operational efficiency, worker safety, and material handling capabilities. As the industry continues to evolve and face new challenges, these versatile attachments are likely to play an increasingly important role in maintaining competitive and sustainable operations.

Landscaping and Tree Removal

In the realm of landscaping and tree removal, excavator wood clamps have emerged as invaluable tools that significantly enhance efficiency, safety, and precision. These versatile attachments have transformed the way landscapers and arborists approach their work, particularly when dealing with large trees or extensive landscaping projects.

One of the primary applications of landscaping is in tree removal operations. When a tree needs to be felled, these clamps can securely grip the trunk, providing stability and control during the cutting process. This is particularly crucial when working in confined spaces or near structures where precision is paramount. Once the tree is felled, the clamp can easily lift and move the trunk and larger branches, streamlining the removal process.

For larger landscaping projects that involve clearing land, wood clamps prove incredibly useful. They can efficiently remove brush, small trees, and stumps, preparing the area for new landscaping features or construction. The strong grip and maneuverability of these clamps allow operators to clear areas quickly while minimizing disturbance to the surrounding landscape.

In tree transplanting operations, wood clamps play a crucial role. They can carefully lift and move entire trees, including the root ball, with minimal damage. This capability is especially valuable in urban landscaping projects where mature trees need to be relocated rather than removed. The precise control offered by the excavator, combined with the secure grip of the clamp, ensures that trees can be transplanted safely and successfully.

Excavator wood clamps are also extensively used in pruning and maintenance of large trees. They can hold branches steady during cutting, improving safety for workers and reducing the risk of property damage from falling limbs. For removing dead or diseased branches high up in a tree, these clamps can provide a stable platform for arborists to work from, enhancing both efficiency and safety.

In landscape construction, these clamps assist in the placement of large landscape features such as boulders or large decorative logs. Their ability to grip and maneuver heavy objects with precision makes them ideal for creating natural-looking rock gardens or rustic wooden features in parks and public spaces.

Storm damage cleanup is another area where wood clamps prove their worth in landscaping. After severe weather events, these attachments can quickly clear fallen trees and large branches, helping to restore safety and aesthetics to damaged landscapes. The efficiency in these situations can significantly speed up recovery efforts in affected communities.

For landscapers working on erosion control projects, excavator wood clamps can assist in placing large logs or root wads along waterways or steep slopes. These natural materials help stabilize soil and create habitats, and the precise placement enabled by the clamps ensures that they are positioned for maximum effectiveness.

As sustainable landscaping practices gain popularity, excavator wood clamps are being used to implement techniques like hugelkultur, where logs and organic matter are buried to create raised garden beds. The clamps can easily move and position large logs, making the creation of these permaculture features more efficient.

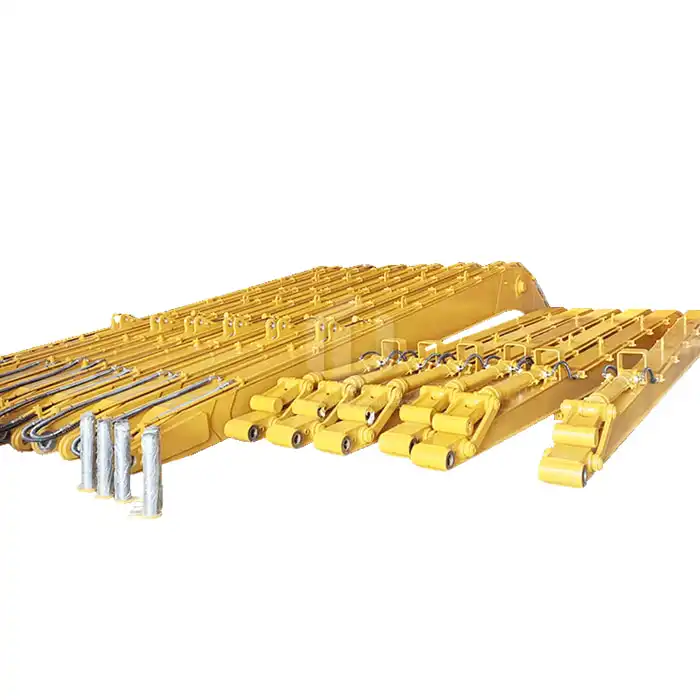

Tiannuo Machinery Excavator Wood Clamps

Excavator wood clamps have proven to be invaluable tools across various industries, from forestry and logging to lumber processing and landscaping. These versatile attachments have significantly enhanced efficiency, safety, and precision in handling wooden materials of all sizes. As technology continues to advance, we can expect to see even more innovative applications for excavator wood clamps, further cementing their importance in these crucial sectors.

Tiannuo offers a range of excavator wood clamps designed to accommodate various excavator sizes and capacities. For 3-5 ton excavators, the clamp provides a 1250mm opening and can handle an unloading weight of up to 500 kg. For 6-10 ton excavators, the opening increases to 1400mm with a capacity of 800KG. The 11-16 ton excavators feature a 1700mm opening and can manage up to 1200 kg. For 17-22 ton excavators, the opening is 1900mm with a capacity of 1800KG. The 23-25 ton excavators have a 2050mm opening and can handle 2300KG. If you are choosing your excavator wood clamps manufacturer, please feel free to reach out to our manager at arm@stnd-machinery.com and the team at rich@stnd-machinery.com and tn@stnd-machinery.com.

References:

- Visser, R., & Stampfer, K. (2015). Expanding Ground-based Harvesting onto Steep Terrain: A Review. Croatian Journal of Forest Engineering, 36(2), 321-331.

- Holm, S., Thees, O., Lemm, R., & Olschewski, R. (2018). Upgrading raw forest biomass: Techno-economic and environmental assessment of processes for central Europe. Biomass and Bioenergy, 119, 390-399.

- Loney, B., & Niemiec, S. S. (2018). Mechanical tree planting in the Pacific Northwest. Journal of Forestry, 116(5), 429-435.