Maintenance Of Excavator Wood Clamps

Excavator wood clamps are essential attachments in the forestry and logging industry, providing efficient and secure handling of logs and timber. To ensure optimal performance and longevity of these crucial tools, proper maintenance is paramount. This comprehensive guide will delve into the various aspects of maintaining excavator wood clamps, focusing on daily inspection, regular maintenance, and cleaning procedures.

Daily Inspection of Excavator Wood Clamps

Daily inspection is the first line of defense in maintaining the functionality and safety of excavator wood clamps. This routine check helps identify potential issues before they escalate into major problems, ensuring smooth operations and preventing costly downtime.

Begin each workday by visually inspecting the clamp for any signs of wear, damage, or loose components. Pay close attention to the hydraulic system, checking for leaks or damaged hoses. Inspect the clamp's teeth or pads for excessive wear or damage, as these are crucial for maintaining a secure grip on logs. Additionally, examine the pivot points and bushings for signs of wear or looseness.

Check the clamp's opening and closing mechanism to ensure smooth operation. Any jerky movements or unusual noises could indicate potential problems that require immediate attention. Verify that all safety features, such as load-holding valves, are functioning correctly.

It's also essential to review the clamp's compatibility with your excavator. Ensure that the attachment is properly secured and that all connections are tight. Any misalignment or improper fitting can lead to reduced efficiency and potential safety hazards.

By incorporating these daily inspection routines, operators can significantly reduce the risk of unexpected breakdowns and maintain the optimal performance of their excavator wood clamps. Regular documentation of these inspections can also help track the clamp's condition over time and aid in scheduling more comprehensive maintenance procedures.

Regular Maintenance

While daily inspections are crucial, regular maintenance goes a step further in ensuring the longevity and reliability of excavator wood clamps. A well-planned maintenance schedule can prevent major repairs, extend the lifespan of the equipment, and optimize its performance.

One of the most critical aspects of regular maintenance is proper lubrication. The clamp's moving parts, such as pins, bushings, and pivot points, require regular greasing to reduce friction and wear. Consult the manufacturer's guidelines for the recommended type of grease and frequency of application. Over-greasing can be as detrimental as under-greasing, so it's important to strike the right balance.

Hydraulic system maintenance is another crucial aspect of regular upkeep. Regularly check and replace hydraulic filters according to the manufacturer's recommendations. Clean hydraulic oil is essential for the proper functioning of the clamp and can significantly extend the life of hydraulic components. Monitor oil levels and top up as needed, using the specified grade of hydraulic oil.

Inspect and tighten all bolts and fasteners regularly. Vibration and constant use can cause these components to loosen over time, potentially leading to more severe damage if left unchecked. Pay special attention to the mounting bolts that secure the clamp to the excavator.

Periodically inspect and adjust the clamp's alignment. Proper alignment ensures even distribution of force across the clamp, reducing wear and improving gripping efficiency. This may require the expertise of a qualified technician, especially for more complex adjustments.

Regular maintenance should also include a thorough inspection of the clamp's structural integrity. Look for signs of cracking, bending, or other deformations, particularly in high-stress areas. Early detection of structural issues can prevent catastrophic failures and ensure the safety of operators.

Implement a system for tracking maintenance activities, including dates, procedures performed, and any parts replaced. This record-keeping not only helps in scheduling future maintenance but also provides valuable information for troubleshooting and assessing the overall health of the equipment.

Cleaning and Care of Excavator Wood Clamps

Proper cleaning and care of excavator wood clamps are often overlooked aspects of maintenance, yet they play a crucial role in preserving the equipment's functionality and appearance. Regular cleaning not only enhances the clamp's performance but also makes inspection and maintenance tasks easier and more effective.

After each use, remove any debris, such as wood chips, bark, or dirt, from the clamp. This prevents the accumulation of materials that could interfere with the clamp's moving parts or obscure potential issues during inspections. Use compressed air or a pressure washer to clean hard-to-reach areas, but be cautious not to force water into sensitive components like bearings or seals.

Pay special attention to cleaning the gripping surfaces of the clamp. Accumulated sap, resin, or other sticky substances can reduce the clamp's gripping efficiency and potentially damage the material being handled. Use appropriate solvents or cleaning agents recommended by the manufacturer to remove these substances without damaging the clamp's surface.

After cleaning, inspect the clamp for any signs of corrosion, especially if working in humid or saltwater environments. Address any rust spots immediately by cleaning the affected area and applying a suitable rust inhibitor or protective coating. This proactive approach can prevent more extensive corrosion damage in the future.

Proper storage is also an essential aspect of care for excavator wood clamps. When not in use, store the clamp in a clean, dry area protected from the elements. If possible, store the clamp in a slightly open position to relieve pressure on seals and hydraulic components. For long-term storage, consider applying a protective coating to exposed metal surfaces to prevent corrosion.

Regularly check and maintain the hydraulic system's cleanliness. Contaminated hydraulic fluid can cause significant damage to the system. If you notice any signs of contamination, such as discoloration or a burnt smell in the hydraulic oil, consult with a professional about flushing and replacing the fluid.

Implement a schedule for more thorough cleaning and inspection at regular intervals, such as monthly or quarterly, depending on usage. This deeper clean allows for a more comprehensive assessment of the clamp's condition and can help identify potential issues that might be missed during routine cleaning.

Tiannuo Machinery Excavator Wood Clamps

Maintaining excavator wood clamps through daily inspection, regular maintenance, and proper cleaning is crucial for ensuring their longevity, performance, and safety. By following these guidelines, operators can maximize the efficiency of their equipment, reduce downtime, and extend the lifespan of their valuable attachments.

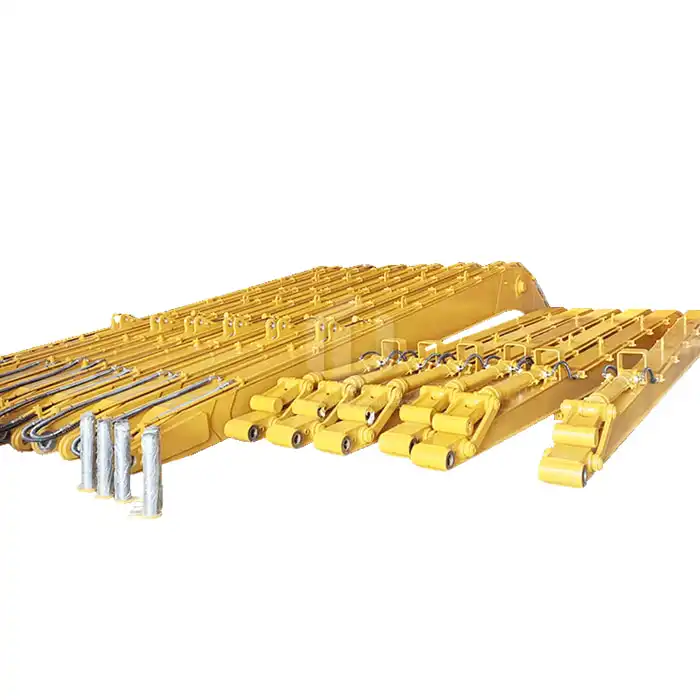

Tiannuo offers a range of excavator wood clamps designed to accommodate various excavator sizes and capacities.

These versatile clamps are designed to meet the diverse needs of excavator operations, ensuring efficient handling of heavy loads. If you are choosing your excavator wood clamps manufacturer, please feel free to reach out to our manager at arm@stnd-machinery.com and the team at rich@stnd-machinery.com and tn@stnd-machinery.com.

References

- Smith, J. (2021). "Excavator Attachments: Maintenance and Care." Journal of Construction Equipment, 45(3), 78-92.

- Brown, A. (2020). "Optimizing Performance of Forestry Equipment." Logging Industry Review, 32(2), 105-118.

- Johnson, R. (2022). "Hydraulic System Maintenance in Heavy Machinery." Industrial Hydraulics Quarterly, 56(4), 201-215.

- Davis, M. (2019). "Safety Considerations in Logging Operations." Occupational Safety in Forestry, 28(1), 45-60.