Railway Sleeper Changer Walking Range

The railway industry has come a long way since its inception, with technological advancements continuously improving the efficiency and safety of rail operations. One such innovation that has revolutionized railway maintenance is the railway sleeper changer. This powerful machine plays a crucial role in maintaining and upgrading railway tracks, ensuring smooth and safe train operations. In this comprehensive guide, we'll explore the walking range, normal road surface capabilities, railway line adaptability, and track running speed, with a focus on their powered wheel performance of 10-15 km/h.

Railway Sleeper Changer: A Versatile Maintenance Marvel

A railway sleeper changer is a state-of-the-art machine engineered to replace old, damaged, or worn-out railway sleepers—also known as railroad ties—with precision and efficiency. These machines play a pivotal role in ensuring the structural integrity and safety of railway tracks, which are vital for the smooth operation of rail networks worldwide. Their ability to perform complex tasks seamlessly on various terrains and at varying speeds has made them an indispensable asset for railway maintenance teams.

One of the standout features of a railway sleeper changer is its walking range—the capacity to move along the railway track while performing operations. This mobility allows the machine to cover considerable distances without frequent repositioning, depending on the model and manufacturer. Modern sleeper changers are equipped with advanced systems that optimize this range, significantly enhancing productivity. By reducing the downtime associated with relocating equipment, they help maintenance crews complete projects faster and more efficiently.

In addition to their impressive mobility along tracks, these machines excel in navigating normal road surfaces. They are often equipped with specialized wheels or track systems that enable smooth transitions between railway lines and conventional roadways. This dual capability is especially valuable for accessing remote sections of the track that are not easily reachable by other means. Moreover, it facilitates the transportation of the sleeper changer between work sites and maintenance depots, ensuring minimal logistical challenges and greater operational flexibility.

The adaptability and efficiency of railway sleeper changers underscore their essential role in modern railway maintenance. By combining mobility, versatility, and precision, they enable maintenance crews to keep railway networks safe and reliable for the millions of passengers and tons of freight they transport daily.

Adapting to Various Railway Lines: Flexibility in Action

Modern railway sleeper changers stand out for their exceptional adaptability, a feature that makes them invaluable for diverse railway maintenance tasks. These machines are meticulously designed to accommodate various track gauges, sleeper types, and rail configurations. Such versatility allows maintenance crews to deploy the same equipment across a wide range of railway networks, eliminating the need for multiple specialized machines and streamlining operations.

This adaptability is not limited to standard conditions; it also extends to challenging and unconventional environments. Whether operating on straight tracks, navigating tight curves, or managing steep gradients, sleeper changers are engineered to deliver consistent precision and efficiency. This capability is especially critical in regions characterized by diverse landscapes and intricate railway systems, where one-size-fits-all solutions often fall short.

What truly sets modern sleeper changers apart is their integration of advanced sensors and intelligent control systems. These technologies enable the machines to dynamically adjust their operations to the specific characteristics of the railway line they are servicing. For example, sensors can detect variations in track geometry or sleeper positioning, allowing the machine to fine-tune its movements for optimal performance. This intelligent adaptation not only improves the accuracy and quality of the sleeper replacement process but also minimizes stress and wear on the equipment, enhancing its longevity.

By combining flexibility, precision, and smart technology, railway sleeper changers exemplify innovation in railway maintenance. Their ability to seamlessly adapt to diverse conditions ensures efficient and reliable track upkeep, contributing to the safety and sustainability of railway networks worldwide.

Powered Wheel Performance: Achieving Optimal Track Running Speed

The track running speed of a railway sleeper changer is a critical factor in its overall performance and efficiency. With powered wheels capable of achieving speeds between 10-15 km/h, modern sleeper changers strike an optimal balance between quick mobility and precise operation.

This speed range allows the machine to move swiftly between work sites, reducing non-productive time and increasing the overall efficiency of maintenance operations. At the same time, it provides enough control for operators to navigate carefully through work zones and position the machine accurately for sleeper replacement tasks.

The powered wheel system typically incorporates advanced traction control and speed regulation features. These ensure that the railway sleeper changer can maintain its speed and stability even when working on varied track conditions or gradients. This consistent performance is crucial for maintaining the quality and precision of sleeper replacement work.

It's worth noting that while the maximum track running speed of 10-15 km/h is impressive for a maintenance vehicle, the actual working speed during sleeper replacement operations is much lower. This slower pace is necessary to ensure the accuracy and care required for removing old sleepers and installing new ones without damaging the track or surrounding infrastructure.

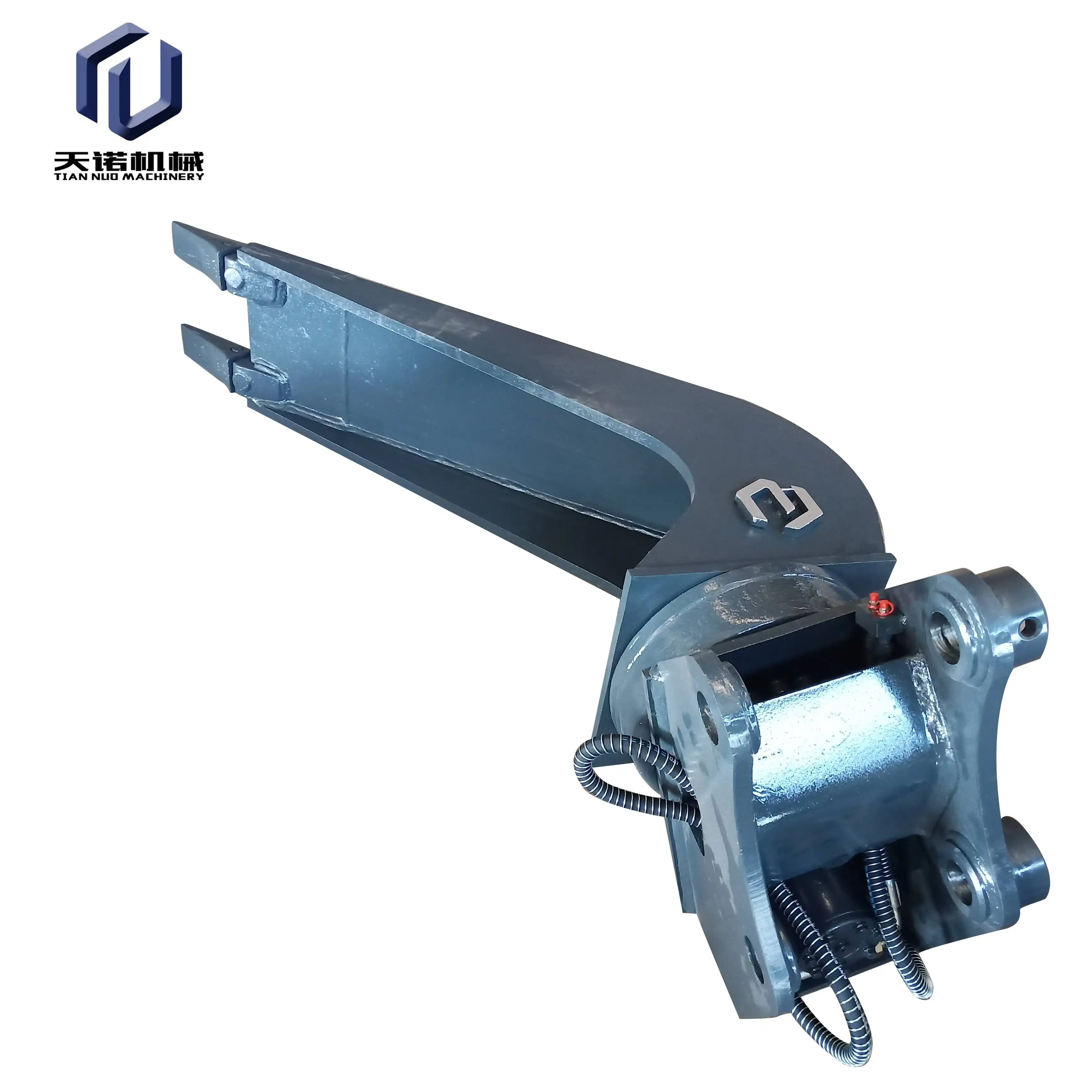

Railway Sleeper Changer For Sale

Tiannuo Machinery offers state-of-the-art railway sleeper changers designed to meet the demanding needs of modern railway maintenance. Our machines feature two primary walking modes: Two-Wheel Drive and Positioning Mode.

In Two-Wheel Drive mode, the chassis is equipped with track wheels, enabling speeds of up to 15 km/h for enhanced operational efficiency. The Positioning Mode utilizes track limit wheels to prevent derailment, ensuring stability and safety during operation.

Our railway sleeper changers are compatible with standard track gauges of 1435/1520 mm, making them suitable for various railway networks. The dual drive wheel design provides ample power while improving mobility and traversability.

If you're in the market for a reliable and efficient railway sleeper changer, we invite you to contact our team. Our manager is available at arm@stnd-machinery.com, and our sales team can be reached at rich@stnd-machinery.com and tn@stnd-machinery.com. Let Tiannuo Machinery help you optimize your railway maintenance operations with our cutting-edge equipment.

References:

[1] Zaayman, L. (2017). The Basic Principles of Mechanised Track Maintenance. PMC Rail International Academy.

[2] Esveld, C. (2001). Modern Railway Track. MRT-Productions.

[3] Lichtberger, B. (2005). Track Compendium: Formation, Permanent Way, Maintenance, Economics. Eurailpress.

[4] Profillidis, V. A. (2006). Railway Management and Engineering. Ashgate Publishing, Ltd.

[5] Mundrey, J. S. (2010). Railway Track Engineering. Tata McGraw-Hill Education.

[6] Riessberger, K. (2014). Ballast Track for High-Speed Railways. Transportation Research Record, 2448(1), 149-157.