How does the 360° rotation feature benefit the operation of the railway sleeper changer?

The railway sleeper changer is an essential piece of equipment in the maintenance and construction of railway tracks. This specialized machine is designed to remove and replace railway sleepers efficiently, ensuring the safety and stability of rail networks. One of the most innovative features is the 360° rotation capability, which has revolutionized the way these machines operate. In this article, we'll explore how this feature significantly enhances its functionality and efficiency, focusing on three key areas: enhanced maneuverability, improved operational efficiency, and precise placement of sleepers.

Enhanced Maneuverability

The 360° rotation feature of modern railway sleeper changers has dramatically improved their maneuverability, making them more versatile and adaptable to various working environments. This enhanced flexibility allows operators to navigate complex track layouts and overcome obstacles with ease, ultimately leading to more efficient and effective sleeper replacement operations.

One of the primary benefits of the 360° rotation feature is the ability to access hard-to-reach areas along the railway track. Traditional sleeper changers often struggled with tight spaces or areas with limited access, but the full rotation capability allows operators to position the machine optimally, regardless of the surrounding terrain or obstacles. This means that even in challenging locations, such as curves, switches, or areas near platforms, the railway sleeper changer can perform its tasks without compromising on efficiency or safety.

Moreover, the improved maneuverability reduces the need for multiple machine repositioning during operations. In the past, operators would often need to move the entire machine to adjust its position or to work on different sections of the track. With the 360° rotation feature, the machine can remain stationary while the working arm rotates to reach different areas, saving valuable time and reducing the risk of accidents associated with frequent machine movements.

The enhanced maneuverability also contributes to better workspace organization. By allowing the machine to rotate fully, operators can position support vehicles, tools, and materials more strategically around the work area. This optimized layout not only improves efficiency but also enhances safety by reducing the likelihood of accidents caused by cluttered or poorly organized work sites.

Improved Operational Efficiency

The 360° rotation feature of railway sleeper changers has significantly improved operational efficiency in several ways. By enabling smoother and more continuous operations, this innovative design has reduced downtime and increased the overall productivity of sleeper replacement projects.

One of the most notable improvements in operational efficiency is the reduction in setup time. Traditional sleeper changers often required extensive positioning and repositioning to work on different sections of the track. With the 360° rotation capability, operators can quickly adjust the machine's working arm to target different areas without moving the entire unit. This drastically cuts down on the time spent on setup and repositioning, allowing more time for actual sleeper replacement work.

The continuous operation facilitated by the 360° rotation also leads to a more consistent work pace. Operators can smoothly transition from one sleeper to the next without interrupting the workflow to reposition the machine. This uninterrupted operation not only increases the number of sleepers that can be replaced in a given time frame but also helps maintain a steady rhythm, which can reduce operator fatigue and improve overall work quality.

Furthermore, the 360° rotation feature allows for better coordination between the sleeper changer and other maintenance vehicles or equipment on site. The ability to rotate the working arm means that the sleeper changer can more easily interact with material supply vehicles, waste removal trucks, or other support equipment without requiring these vehicles to constantly reposition themselves. This improved coordination streamlines the entire operation, reducing delays and enhancing overall project efficiency.

The increased efficiency also translates to cost savings. By completing sleeper replacement tasks more quickly and with less downtime, railway maintenance teams can reduce labor costs and minimize the duration of track closures. This is particularly crucial in busy rail networks where every minute of track downtime can have significant economic implications.

Precise Placement of Sleepers

The 360° rotation feature of modern railway sleeper changers has revolutionized the precision with which sleepers can be placed. This enhanced accuracy is crucial for ensuring the long-term stability and safety of railway tracks, as well as minimizing the need for future adjustments or repairs.

One of the primary advantages of the 360° rotation capability is the improved control it offers operators during the sleeper placement process. The ability to rotate the working arm allows for fine adjustments in positioning, ensuring that each sleeper is placed exactly where it needs to be. This level of precision is particularly important when dealing with complex track geometries, such as curves or gradients, where even small misalignments can have significant impacts on track performance and safety.

The enhanced precision also contributes to better quality control during the sleeper replacement process. With the ability to rotate and position the sleeper changer's arm exactly as needed, operators can more easily perform visual inspections and measurements to ensure that each sleeper is placed correctly. This attention to detail helps maintain consistent track gauge and alignment, which are critical factors in ensuring smooth and safe rail operations.

Moreover, the precise placement capabilities enabled by the 360° rotation feature can lead to improved track longevity. When sleepers are positioned accurately, they distribute the load from passing trains more evenly, reducing wear and tear on both the sleepers themselves and the surrounding track infrastructure. This can extend the lifespan of the track and decrease the frequency of required maintenance, leading to long-term cost savings for railway operators.

The precision offered by the 360° rotation feature is particularly valuable when working with modern concrete sleepers, which often have more stringent placement requirements than traditional wooden sleepers. The ability to make minute adjustments ensures that these sleepers are installed to the exact specifications required, maximizing their performance and durability.

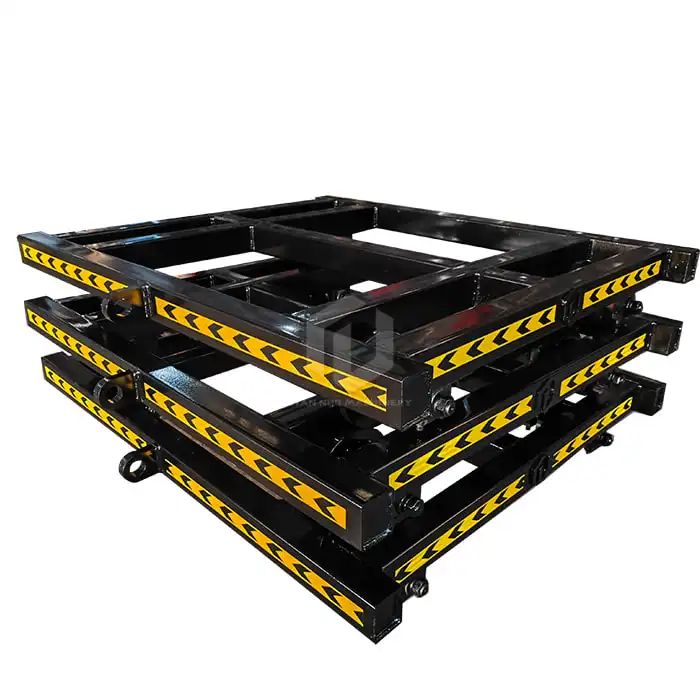

Railway Sleeper Changer For Sale

The 360° rotation feature has undoubtedly revolutionized the operation of sleeper changers, offering significant benefits in terms of maneuverability, operational efficiency, and precise sleeper placement. These improvements not only enhance the speed and quality of track maintenance but also contribute to the overall safety and longevity of railway networks.

For those in the market for a state-of-the-art railway sleeper changer, Tiannuo Machinery offers cutting-edge solutions designed to meet the demanding requirements of modern railway maintenance. Our products feature advanced technology, including the versatile walking modes that enhance operational flexibility and efficiency.

The walking modes of Tiannuo Machinery's sleeper changer include two primary configurations: Two-Wheel Drive and Positioning Mode. In the Two-Wheel Drive mode, the chassis is equipped with track wheels, allowing the machine to achieve speeds of up to 15 km/h, which significantly enhances operational efficiency. In the Positioning Mode, the chassis is fitted with track limit wheels to prevent the machine from derailing, ensuring stability and safety during operation.

Our machines are designed to be compatible with standard track gauges of 1435/1520 mm, meeting the requirements of various railway networks worldwide. Equipped with two drive wheels, our railway sleeper changers not only provide sufficient power but also enhance mobility and traversability. These design features ensure that our machines maintain high operational efficiency while guaranteeing the safety and flexibility of operations.

If you're looking for a reliable and efficient railway sleeper changer manufacturer, we invite you to explore what Tiannuo Machinery has to offer. For more information or to discuss your specific needs, please don't hesitate to contact our team:

- Manager's email: arm@stnd-machinery.com

- Team emails: rich@stnd-machinery.com and tn@stnd-machinery.com

Experience the difference that advanced technology and expert engineering can make in your railway maintenance operations with Tiannuo Machinery.

References:

- Railway Technology (2021). "Advancements in Railway Maintenance Equipment"

- International Railway Journal (2020). "Improving Efficiency in Track Maintenance"

- Safety Science (2019). "Workplace Safety in Railway Maintenance Operations"

- Journal of Rail Transport Planning & Management (2018). "Optimizing Railway Maintenance Procedures"

- Ergonomics (2020). "Human Factors in Railway Maintenance Equipment Design"

_1740558626327.webp)