How to design the ballast cleaner machine body?

Ballast cleaner machines are essential to the long-term viability and safety of the rail infrastructure when it comes to track maintenance. These strong machines are intended to eliminate sullied counterweight and supplant it with clean material, keeping up with appropriate waste and track solidness. The design of a ballast cleaner machine's body, particularly the shape of the bucket, is one of its most important parts. The intricacies of designing a body for a ballast cleaner machine will be the focus of this article, with a focus on the popular crescent bucket design and its benefits.

Importance Of Bucket Design In Ballast Cleaner Machines

A ballast cleaner machine's primary component that comes into direct contact with the ballast material is the bucket. The machine's efficiency, effectiveness, and overall performance are significantly impacted by its design. Engineers must take into account the capacity of the ballast cleaner machine, the kind of ballast being cleaned, and the particular requirements of the railway maintenance project when designing the machine's body.

The crescent shape is one of the most well-liked and efficient bucket designs for ballast cleaner machines. Since this one-of-a-kind arrangement has proven to be very effective at removing and cleaning ballast, many contractors and railway maintenance companies favor it.

Why Choose a Crescent Bucket Design?

There are a number of advantages to the crescent bucket design that make it a good choice for ballast cleaner machines:

Enhanced Scooping Performance: The crescent bucket's curved design makes scooping easier and more natural. The machine can collect more ballast material in a single pass thanks to this design, increasing overall efficiency and reducing cleaning time.

A better flow of material: The bucket's crescent shape makes it easier for materials to flow through it. The ballast naturally follows the bucket's curve as the machine moves, decreasing the likelihood of material becoming stuck or compacted.

Better segregation: The crescent bucket's unique curvature makes it easier to separate larger debris from smaller ballast particles in the beginning. Pre-sorting can improve the cleaning process as a whole and lessen the strain on the screening parts of the machine.

Enhanced Resilience: The shape of the crescent disperses the forces that are applied to the bucket more evenly, which reduces wear and tear at specific points. Over time, this design feature may help the bucket last longer and save money on maintenance.

Due to these advantages, manufacturers of ballast cleaner machines like Shandong Tiannuo Machinery favor the crescent bucket design. Their dedication to research and development has resulted in the development of highly effective machines like the TNQZD75 model, which combines cutting-edge design features to enhance performance and dependability.

Advantages Of Crescent Bucket Design In Gravel Cleaning

The crescent bucket design has a few distinct advantages for cleaning gravel:

Enhanced Permeation: The bucket's curved shape makes it easier to get into the ballast bed. The machine can reach deeper layers of contaminated gravel thanks to this design feature, ensuring a more thorough cleaning procedure.

Reduced Loss of Material: During the process of scooping and lifting, the shape of the crescent helps keep the gravel contained within the bucket. Material spillage is reduced and more ballast is processed through the cleaning system thanks to this containment.

Enhanced Efficiency of Screening: A preliminary screening process is performed on the gravel as it moves along the bucket's curved surface. This initial separation may boost the effectiveness of subsequent cleaning steps, resulting in cleaner ballast of higher quality.

Ability to adapt to a variety of ballast conditions: The crescent bucket design is adaptable and capable of effectively handling various sizes and types of gravel. Because of its adaptability, it is suitable for a wide range of ballast conditions and railway maintenance projects.

Ballast cleaner machines with crescent buckets are favored by many railway maintenance operations due to their overall efficiency and effectiveness thanks to these benefits.

Alternative Bucket Shapes For Ballast Cleaner Machines

For ballast cleaner machines, there are other bucket shapes available, each with its own set of advantages, despite the crescent bucket design's widespread popularity:

Straight Container: The sides and bottom of this traditional design are straight. While it may not offer a similar liquid scooping movement as the sickle pail, it very well may be viable in specific circumstances, especially while managing compacted counterweight.

Bucket in a V shape: The V-shaped cross-section of this design makes it possible to channel material toward the bucket's center. When working with ballast that is either loose or easily scattered, this shape can be especially helpful.

Bucket for Combination: Buckets made by some manufacturers combine elements of various designs. A bucket, for instance, might have straight sides and a bottom that is shaped like a crescent to combine the benefits of several designs.

Bucket with holes: The surface of the bucket has small slots or holes in it, allowing for the screening and drainage of excess water prior to scooping. When the ballast is wet or clogged with water, this feature can be especially helpful.

The specific requirements of the railway maintenance project, the kind of ballast being cleaned, and the operating conditions ultimately determine the bucket shape. Various bucket designs are available from numerous manufacturers, including Shandong Tiannuo Machinery, to meet a variety of requirements and preferences.

Conclusion

In conclusion, the performance and effectiveness of ballast cleaner machines are significantly affected by the body design, particularly the bucket shape. Scooping efficiency, material flow, and overall cleaning performance are all advantages of the crescent bucket design, which has proven to be highly effective in numerous applications. However, there are alternative bucket shapes that may be more appropriate for particular circumstances. In order to find the ideal ballast cleaner machine for your railway maintenance requirements, it is essential to take the bucket design into consideration.

Shandong Tiannuo Machinery can be contacted at tiannuojixie@railwayexcavatorattachments.com if you are interested in learning more about cutting-edge ballast cleaner machines and the designs that go along with them. Their team of experts can give you useful advice and assist you in selecting the appropriate machine for your needs.

References

1. Railway Track Engineering by J.S. Mundrey

2. Handbook of Railway Vehicle Dynamics by Simon Iwnicki

3. Track Geotechnology and Substructure Management by Ernest T. Selig and John M. Waters

4. Railway Maintenance Equipment: The Art of Track Maintenance by Frank J. Ackerman

YOU MAY LIKE

VIEW MOREUnloading Arm Steel Grabbing Machine

VIEW MOREUnloading Arm Steel Grabbing Machine VIEW MOREExcavator Grab Arm

VIEW MOREExcavator Grab Arm VIEW MORERail-Road Ballast Undercutter Excavator

VIEW MORERail-Road Ballast Undercutter Excavator VIEW MOREUnloading Train Excavator Long Legs

VIEW MOREUnloading Train Excavator Long Legs VIEW MORETruck Anti-Skid Track

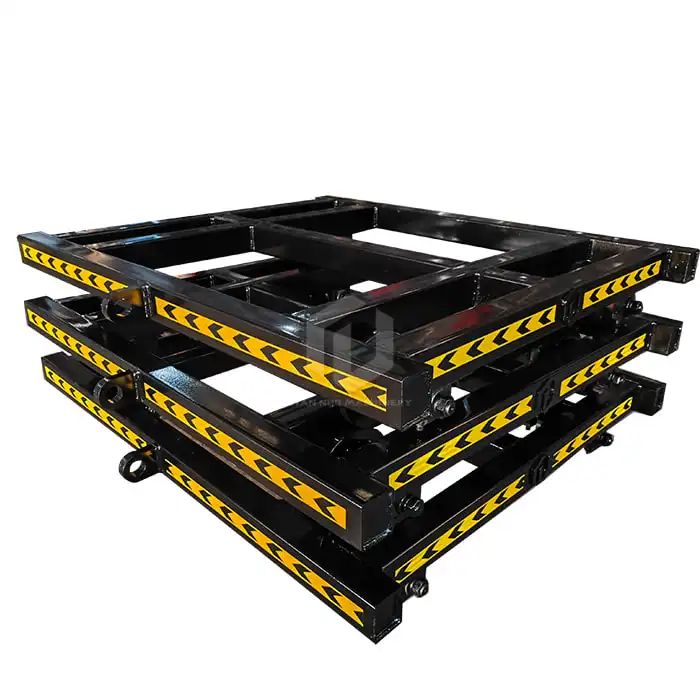

VIEW MORETruck Anti-Skid Track VIEW MOREExcavator Special-Shaped Bucket

VIEW MOREExcavator Special-Shaped Bucket VIEW MORERail Track Trolley

VIEW MORERail Track Trolley VIEW MOREExcavator Hydraulic Rail Clamp

VIEW MOREExcavator Hydraulic Rail Clamp