Excavator Rail Clamp Replacement

The excavator rail clamp is a crucial component in ensuring both safety and efficiency in the construction and maintenance of railways. These clamps are a crucial part of attachments for railway excavators and are designed to securely grasp and manipulate rail tracks during a variety of tasks. However, because rail clamps, like all mechanical equipment, are subject to wear and tear, replacing them is an essential part of railway maintenance. We will discuss the significance of rail clamps, the need for prompt replacement, and helpful advice for a hassle-free replacement procedure in this comprehensive guide.

Importance Of Rail Clamps In Railway Operations

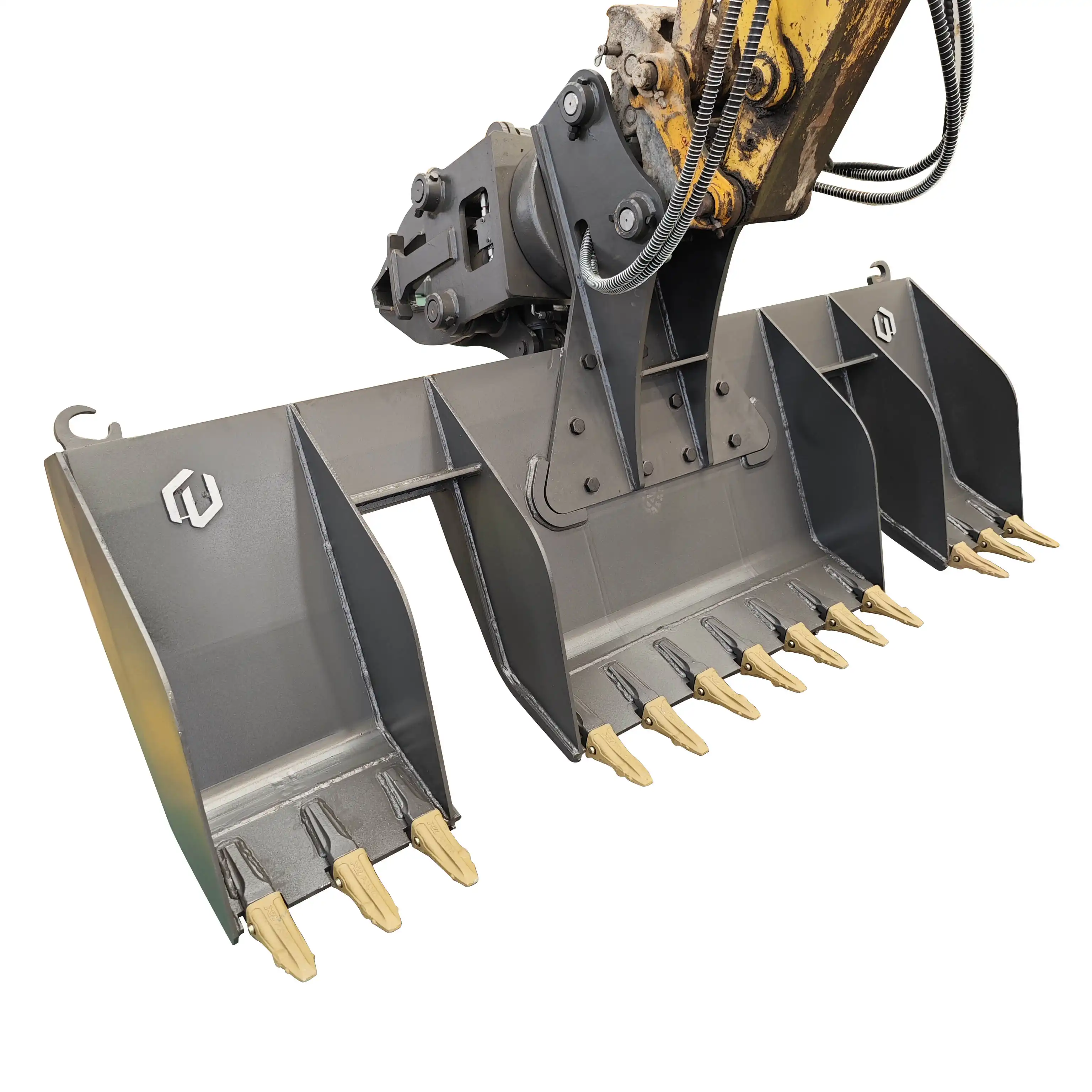

Excavator rail clamps are specialized attachments that enable excavators to handle railway tracks safely and effectively. Operators can lift, move, and position tracks with precision using these robust devices, which are designed to securely grip rails. Rail clamps are crucial to the safety, efficiency, and overall success of track maintenance and construction projects, so their significance in railway operations cannot be overstated.

A stable and secure grip on railway tracks is one of an excavator rail clamp's primary functions. This is critical for different undertakings, including track substitution, realignment, and establishment of new segments. The clamp's ability to hold the rail securely ensures the safety of workers and equipment on the job site by preventing slippage and potential accidents.

Additionally, excavators with rail clamps are more adaptable to working in railway environments. These attachments enable contractors to make the most of the equipment they already have by turning standard excavators into specialized rail handling machines. Companies can use a single machine for multiple tasks without requiring rail-specific equipment, which results in cost savings and increased operational efficiency.

Excavator rail clamps' significance is further bolstered by the precision they provide. Working with railroad tracks can result in significant consequences for even the smallest deviations. Rail clamps make it possible for workers to adjust the spacing and alignment of the tracks with millimeter-level precision. The railway system's integrity and the safety of train operations depend on this level of precision.

Necessity Of Timely Rail Clamp Replacement

Even though excavator rail clamps are designed to withstand the rigors of railroad work, they can still get damaged. These essential attachments can degrade over time due to a variety of factors, making their replacement a necessity rather than an option.

The natural wear that results from regular use is one of the primary reasons to replace rail clamps. Components can wear out as a result of the constant gripping and releasing of rails, exposure to the elements in the environment, and high forces involved in manipulating the track. Reduced gripping force, misalignment of the clamp's jaws, or damage to the clamp's hydraulic system are all signs of this wear.

Rail clamp wear is a significant risk in railway operations, where safety is of the utmost importance. Dropped rails, misaligned tracks, and even more serious accidents could result from a clamp's inability to grip securely. Operators can maintain a high level of safety on the job site and avoid potential incidents that could cause injury or damage to equipment by replacing rail clamps before they reach a critical point of wear.

Additionally, the proper operation of all equipment, including rail clamps, is crucial to the efficiency of railway operations. Adjustments and repairs to clamps may become more frequent as they wear out, increasing downtime and decreasing productivity. Proper replacement ensures that operations continue without incident, that project deadlines are met, and that costs remain low.

Notably, advancements in rail clamp technology have also made replacement a viable option. The gripping force, durability, and compatibility with modern excavator systems that are found in newer models are all common improvements. In terms of performance and durability, upgrading to a more recent rail clamp may offer advantages in the long run.

Steps And Tips For Effective Rail Clamp Replacement

In order to ensure a smooth transition and minimal downtime, replacing an excavator rail clamp necessitates careful planning and execution. The following are some important steps and advice to follow:

Selection and Evaluation: To get started, take a thorough look at your rail clamp's current state and choose the best replacement. Consider factors, for example, similarity with your tractor model, the particular prerequisites of your railroad projects, and any mechanical enhancements that could help your tasks. Talking with respectable producers like Shandong Tiannuo can assist you with settling on an educated choice.

Preparation: Make sure you have all the tools and equipment you need before starting the replacement process. Hydraulic wrenches, lifting equipment, and safety gear are examples of this. The new rail clamp must also be on hand and prepared for installation.

Safety precautions: Ensure your safety at all times during the replacement process. Make certain that the excavator is on firm ground, that the engine is turned off, and that all hydraulic pressure has been released. Utilize the appropriate personal protective equipment (PPE) and adhere to all applicable safety procedures.

Dismantling the Old Clamp: Disconnect the hydraulic lines with care and note their configuration so that they can be reinstalled later. Take out any fasteners or bolts that were holding the old clamp to the arm of the excavator. To safely remove the previous clamp, make use of the appropriate lifting equipment.

Putting in the New Clamp: Carefully place the new rail clamp so that it is properly aligned with the excavator arm. Use the appropriate fasteners to secure it, making sure to tighten them according to the manufacturer's instructions. Reconnect the hydraulic lines in a manner that is consistent with the previous configuration.

Calibration and Evaluation: Test the new rail clamp thoroughly after it has been installed to make sure it works as intended. This includes making sure the door opens and closes smoothly, that the grip is strong, and that there are no leaks in the hydraulic system. Follow the manufacturer's instructions and your particular operational requirements when calibrating the clamp.

Training and Acquaintance: Provide operators with sufficient training if the new rail clamp features any new technologies or operating procedures. They can use the new equipment safely and effectively as a result of this.

When looking for a new rail clamp, you should think about advanced features that can make your work easier. For instance, the rail clamps manufactured by Shandong Tiannuo have a maximum opening of 415 mm, making them adaptable to a variety of rail sizes. You will receive cutting-edge technology that has been developed to meet the stringent requirements of railway contractors, maintenance companies, and government agencies worldwide because of their dedication to research and development.

For your new rail clamp to last as long as possible and perform at its best, it needs to be maintained on a regular basis. Lay out a standard examination and support plan, including customary cleaning, oil of moving parts, and brief tending to any issues that emerge.

Conclusion

In conclusion, maintaining safe and effective railway operations necessitates the replacement of excavator rail clamps. Railway professionals can ensure that their equipment remains in top condition by understanding the significance of these attachments, recognizing the signs of replacement, and carefully replacing them. Don't hesitate to contact Shandong Tiannuo at tiannuojixie@railwayexcavatorattachments.com if you're looking for high-quality rail clamps or expert guidance on replacing them. They are an excellent partner for your rail clamp requirements due to their dedication to technological advancement and expertise in railway sleeper changing machines.

References

1. Railway Technology. (2021). "The importance of rail maintenance in ensuring safety and efficiency."

2. Journal of Rail Transport Planning & Management. (2020). "Advancements in railway maintenance equipment and techniques."

3. International Railway Journal. (2022). "Safety considerations in railway construction and maintenance operations."

4. Construction Equipment Magazine. (2021). "Selecting the right attachments for railway excavators."