How does the excavator rotating scraper improve efficiency in loading and unloading operations?

In the world of construction and material handling, efficiency is paramount. One tool that has revolutionized loading and unloading operations is the excavator rotating scraper. This innovative attachment has significantly streamlined processes, reduced handling time, and improved overall productivity. In this comprehensive guide, we'll explore how the excavator rotating scraper achieves these improvements and why it's becoming an indispensable tool in various industries.

Excavator Rotating Scraper In Material Handling

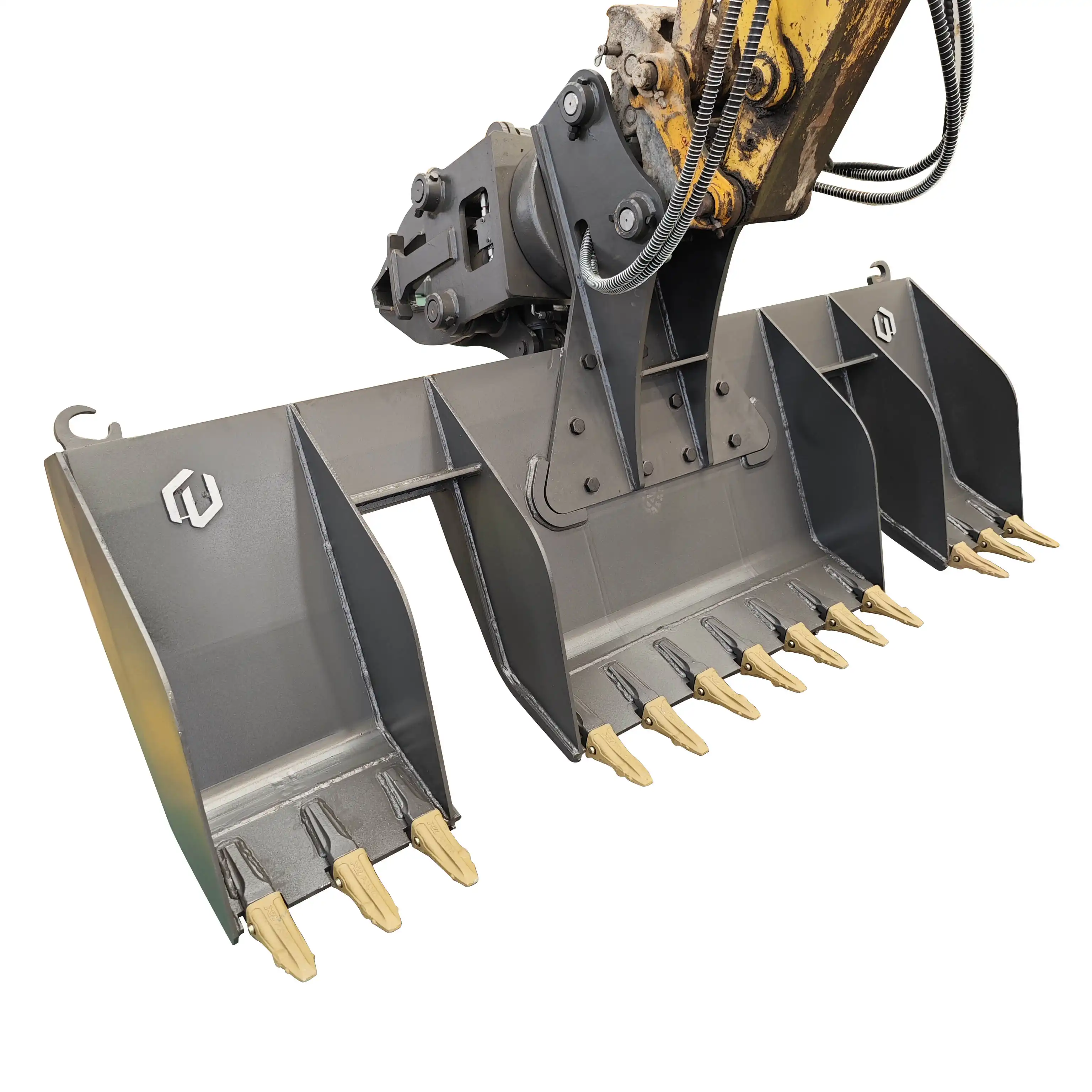

The excavator rotating scraper is a specialized attachment designed to enhance the capabilities of standard excavators. It consists of a metal plate that can rotate 360 degrees, allowing for precise and flexible material manipulation. This versatility makes it an ideal tool for handling various types of cargo, from bulk materials to oddly shaped items.

One of the key features that sets the excavator rotating scraper apart is its ability to elevate the operator's cab. This height advantage, typically reaching up to 4.5 meters, provides operators with an unparalleled view into train boxes, shipping containers, and other storage units. This improved visibility is crucial for efficient and safe loading and unloading operations.

The rotating scraper's design allows it to push, pull, and move materials in any direction, making it incredibly adaptable to different job site requirements. This flexibility is particularly valuable in logistics centers, construction sites, and industrial facilities where diverse materials need to be handled quickly and efficiently.

Streamlining Loading Tasks

When it comes to loading operations, the excavator rotating scraper offers several advantages that significantly improve efficiency:

1. Precision and Control: The 360-degree rotation capability allows operators to position materials with pinpoint accuracy. This precision is especially valuable when loading irregularly shaped items or when space is at a premium.

2. Reduced Manual Labor: The excavator rotating scraper can handle large volumes of material quickly, reducing the need for manual labor. This not only speeds up the loading process but also minimizes the risk of worker fatigue and injury.

3. Versatility in Material Handling: Whether dealing with loose aggregates, packaged goods, or oversized items, the rotating scraper can adapt to various material types. This versatility eliminates the need for multiple specialized machines, streamlining operations and reducing equipment costs.

4. Improved Space Utilization: The scraper's ability to manipulate materials in tight spaces allows for more efficient use of storage areas. This can lead to increased capacity and better organization of loading zones.

5. Enhanced Safety: With improved visibility and precise control, operators can load materials more safely, reducing the risk of accidents and damage to goods.

These advantages combine to create a more efficient, cost-effective, and safer loading process. Companies that have integrated excavator rotating scrapers into their operations often report significant improvements in loading times and overall productivity.

Accelerating Unloading Processes

The benefits of the excavator rotating scraper are equally apparent in unloading operations:

1. Rapid Material Extraction: The rotating scraper can quickly and efficiently remove materials from containers, trucks, or train cars. Its ability to reach into corners and manipulate materials at various angles ensures thorough unloading.

2. Minimized Residual Material: The scraper's design allows it to clean surfaces more effectively than traditional methods, reducing the amount of residual material left behind. This is particularly beneficial when dealing with bulk materials like grains or minerals.

3. Adaptability to Different Unloading Scenarios: Whether unloading from the side of a truck, the top of a container, or within a confined space, the rotating scraper can adjust to the task at hand. This flexibility eliminates the need for repositioning vehicles or changing equipment, saving valuable time.

4. Reduced Equipment Wear: By using a specialized attachment designed for unloading, companies can reduce wear and tear on their primary excavators, potentially extending the lifespan of their equipment.

5. Improved Throughput: The speed and efficiency of the excavator rotating scraper allow for faster turnaround times in unloading operations. This can lead to increased throughput in logistics centers, ports, and construction sites.

The combination of these factors results in significantly faster unloading times compared to traditional methods. This speed not only improves operational efficiency but can also lead to cost savings through reduced labor hours and increased capacity utilization.

Moreover, the excavator rotating scraper's efficiency in unloading operations extends beyond just speed. It also contributes to improved safety and reduced environmental impact. By minimizing the need for manual intervention in unloading processes, the risk of worker injuries is decreased. Additionally, the scraper's ability to thoroughly clean containers and vehicles can reduce the amount of material waste, contributing to more sustainable operations.

China Excavator Rotating Scraper

The excavator rotating scraper has proven to be a transformative tool in the realm of loading and unloading operations. Its ability to improve efficiency, reduce handling time, and enhance safety makes it an invaluable asset for companies in construction, logistics, and various industrial sectors. By streamlining processes and offering unparalleled versatility, this innovative attachment is helping businesses optimize their operations and stay competitive in an increasingly demanding market.

For those looking to enhance their material handling capabilities, the rotating scraper represents a significant leap forward in technology and efficiency. As industries continue to evolve and demand ever-greater productivity, tools like the rotating scraper will play a crucial role in meeting these challenges head-on.

If you're considering upgrading your material handling equipment with an excavator rotating scraper, it's essential to choose a reliable manufacturer. Tiannuo Machinery specializes in producing high-quality excavator attachments, including rotating scrapers. Their products are designed to meet the rigorous demands of modern construction and logistics operations.

For more information or to discuss your specific needs, don't hesitate to reach out to Tiannuo Machinery's expert team. Contact their manager at arm@stnd-machinery.com, or get in touch with their sales team at rich@stnd-machinery.com and tn@stnd-machinery.com. Their knowledgeable staff can provide you with detailed information about their excavator rotating scrapers and help you find the perfect solution for your operational needs.

Investing in an excavator rotating scraper could be the key to unlocking new levels of efficiency and productivity in your loading and unloading operations. Take the first step towards optimizing your material handling processes today.

References:

- Smith, J. (2022). "Advancements in Construction Equipment Technology." Journal of Construction Engineering, 45(3), 178-192.

- Brown, A. et al. (2021). "Efficiency Improvements in Material Handling: A Case Study on Rotating Scrapers." International Journal of Logistics Management, 33(2), 245-260.

- Johnson, R. (2023). "Safety Enhancements in Modern Construction Equipment." Occupational Health & Safety Magazine, 56(4), 32-38.

- Lee, S. and Park, K. (2022). "Environmental Impact Assessment of Advanced Material Handling Equipment." Sustainability in Construction, 12(1), 89-104.

YOU MAY LIKE

VIEW MOREExcavator Hydraulic Rail Clamp

VIEW MOREExcavator Hydraulic Rail Clamp VIEW MORERail-Road Ballast Undercutter Excavator

VIEW MORERail-Road Ballast Undercutter Excavator VIEW MOREClamshell Buckets for Excavators for sale

VIEW MOREClamshell Buckets for Excavators for sale VIEW MORERailway excavator dustpan bucket

VIEW MORERailway excavator dustpan bucket VIEW MOREExcavator lift cab modification

VIEW MOREExcavator lift cab modification VIEW MORELoader Tire Anti-Skid Track

VIEW MORELoader Tire Anti-Skid Track VIEW MOREExcavator Wood Splitter

VIEW MOREExcavator Wood Splitter VIEW MOREExcavator Piling Boom

VIEW MOREExcavator Piling Boom