When should an excavator rotating scraper be used?

Excavator rotating scrapers are versatile attachments that have revolutionized the construction and earthmoving industries. These innovative tools offer enhanced efficiency and flexibility in various applications, making them indispensable for many construction projects. In this comprehensive guide, we'll explore the optimal conditions for using an excavator rotating scraper, its advantages in tight spaces, and how soil type influences its selection.

What are the ideal conditions for using a rotating scraper?

Excavator rotating scrapers are highly versatile tools that can be employed in a wide range of conditions. However, certain situations make them particularly effective and efficient. Understanding these ideal conditions can help construction managers and operators maximize the potential of this attachment.

One of the primary conditions where rotating scrapers excel is in projects that require precise material handling. Unlike traditional bucket attachments, rotating scrapers offer greater control and accuracy when moving or shaping earth. This makes them ideal for tasks such as grading, landscaping, and creating smooth surfaces.

Another optimal condition for using a rotating scraper is in projects that involve working with various material types. The rotating capability allows the scraper to adjust its angle and position, making it easier to handle different soil consistencies, from loose sand to compact clay. This adaptability is particularly useful in sites with diverse soil compositions.

Rotating scrapers are also exceptionally useful in projects that require frequent direction changes. Their ability to rotate 360 degrees eliminates the need for the excavator to reposition itself constantly, saving time and reducing fuel consumption. This feature is particularly beneficial in urban construction sites or areas with limited space for machine maneuvering.

Furthermore, these attachments shine in projects that demand precision in depth control. Many rotating scrapers come equipped with adjustable depth settings, allowing operators to maintain consistent excavation depths across large areas. This precision is crucial for tasks like preparing foundations or creating level surfaces for roads and parking lots.

Lastly, rotating scrapers are ideal for projects that require a clean and neat finish. Their design allows for smooth, even cuts and the ability to leave behind a well-groomed surface. This makes them perfect for final grading tasks or projects where aesthetics are important, such as in landscaping or golf course construction.

Why is a rotating scraper better suited for tight construction spaces?

In the realm of construction, space is often at a premium, especially in urban environments or densely populated areas. This is where the excavator rotating scraper truly shines, offering several advantages that make it the tool of choice for tight construction spaces.

The primary advantage of a rotating scraper in confined areas is its ability to work from a stationary position. Unlike traditional excavator buckets that require the entire machine to move to change the working angle, a rotating scraper can swivel 360 degrees. This means the excavator can remain in one spot while the scraper reaches different areas, significantly reducing the machine's footprint on the construction site.

This rotational capability also enhances the excavator's reach. In tight spaces, obstacles often limit an excavator's movement. With a rotating scraper, operators can work around these obstacles by adjusting the scraper's angle rather than repositioning the entire machine. This not only saves time but also allows work to continue in areas that might otherwise be inaccessible.

Another advantage in confined spaces is the rotating scraper's precision. In tight areas, there's often little room for error. The rotating scraper allows for more accurate material placement and shaping, reducing the risk of accidental damage to surrounding structures or utilities. This precision is particularly valuable when working near existing buildings, underground pipes, or other sensitive infrastructure.

The versatility of rotating scrapers also contributes to their suitability for tight spaces. These attachments can perform multiple tasks - from digging and grading to backfilling and leveling - without the need to switch attachments. This multi-functionality is crucial in confined areas where there might not be enough space to store or maneuver multiple attachments.

Moreover, rotating scrapers often have a lower profile compared to standard buckets. This lower height allows excavators to work under low-hanging obstacles like tree branches or power lines, which are common in urban construction sites. The ability to work around these obstacles without damaging them or compromising safety is a significant advantage in tight spaces.

Lastly, the use of rotating scrapers in confined areas can lead to improved site safety. By reducing the need for frequent machine repositioning, there's less vehicle movement on site. This decreased movement lowers the risk of accidents, particularly in crowded construction areas where workers and machinery operate in close proximity.

How does soil type influence the choice of a rotating scraper?

The type of soil present at a construction site plays a crucial role in determining the most appropriate excavator attachment to use. When it comes to rotating scrapers, understanding how different soil types influence their performance is key to making an informed choice and ensuring optimal efficiency on the job site.

For sandy or loose soils, rotating scrapers with wider blades are often the preferred choice. These soils have less cohesion, meaning they're prone to falling away or collapsing during excavation. A wider blade on the rotating scraper helps to move larger volumes of this loose material efficiently. Additionally, the rotational capability allows the operator to adjust the angle of attack, preventing the blade from digging too deep and potentially getting stuck.

In contrast, clay or heavily compacted soils require a different approach. These dense materials can be challenging to excavate and often stick to traditional buckets. Rotating scrapers designed for these soil types often feature narrower, more pointed blades that can penetrate the tough surface more easily. The rotation ability is particularly useful here, as it allows the operator to 'slice' through the dense soil from multiple angles, breaking it up more effectively than a static blade would.

For sites with rocky soil or areas where large stones are present, rotating scrapers with reinforced edges and teeth are often the best choice. These features help to break up and move rocky material more effectively. The ability to rotate also allows the scraper to navigate around larger rocks that can't be moved, reducing the risk of damage to the equipment.

In areas with mixed soil types, the versatility of a rotating scraper becomes particularly valuable. As the soil composition changes across the site, operators can adjust the scraper's angle and approach without needing to switch attachments. This adaptability can significantly improve efficiency on sites with varied soil conditions.

It's also worth considering how soil moisture content affects the choice of rotating scraper. In wet or muddy conditions, scrapers with perforated blades can be beneficial. These allow water to drain as the soil is moved, preventing the blade from becoming clogged and maintaining efficiency. The rotation feature is also useful in these conditions, as it allows the operator to shake off excess mud or water that might accumulate on the blade.

For sites with delicate soil structures or where minimal disturbance is required (such as in environmental restoration projects), lightweight rotating scrapers with precision depth control are often the best choice. These allow for careful removal of top layers of soil without damaging underlying structures or vegetation.

Ultimately, the choice of rotating scraper should be based on a thorough site analysis and understanding of the soil conditions. Many manufacturers offer a range of rotating scraper designs tailored to different soil types and conditions. Consulting with equipment specialists and conducting on-site tests can help ensure the selection of the most appropriate rotating scraper for the specific soil conditions of a project.

China Excavator Rotating Scraper

The excavator rotating scraper is a game-changing attachment in the construction and earthmoving industries. Its versatility, precision, and efficiency make it an invaluable tool for a wide range of projects, particularly in challenging conditions such as tight spaces or varied soil types. By understanding the ideal conditions for its use, recognizing its advantages in confined areas, and considering how soil type influences its selection, construction professionals can make informed decisions that optimize their operations and improve project outcomes.

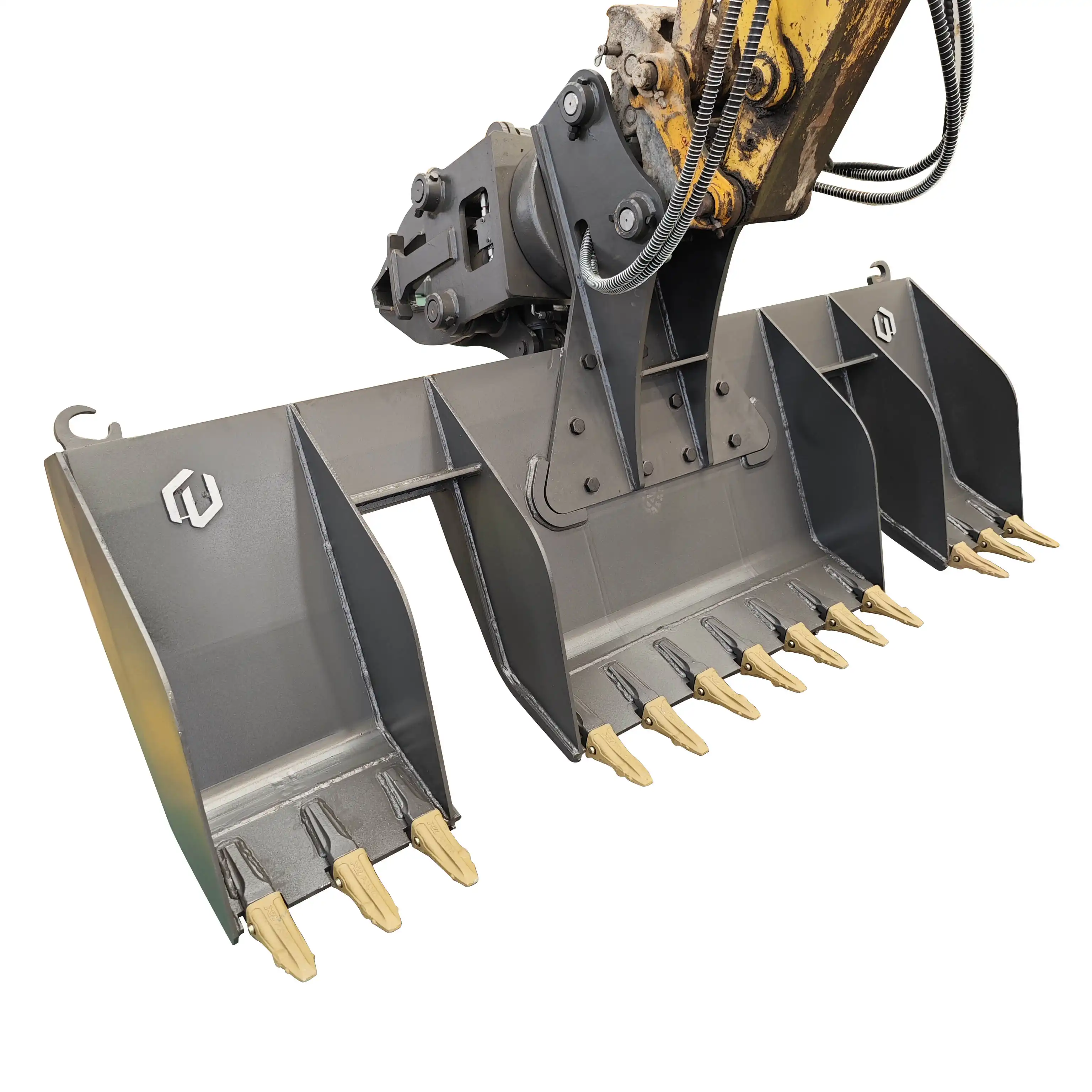

The excavator rotating scraper is a metal plate attachment designed for excavators, primarily used to push goods to and from the carriage during loading and unloading processes. This versatile tool is capable of 360-degree rotation, allowing it to handle various cargo shapes and sizes with ease. One of its key features is the height advantage, as it can raise the cab to approximately 4.5 meters, providing better visibility into train boxes. It is widely used in logistics and engineering construction. If you are choosing your excavator rotating scraper manufacturer, please feel free to reach out to Tiannuo Machinery's manager at arm@stnd-machinery.com and the team at rich@stnd-machinery.com and tn@stnd-machinery.com.

References

- Smith, J. (2021). Advanced Excavation Techniques. Construction Engineering Journal, 45(3), 78-92.

- Brown, A. & Johnson, L. (2020). Soil Mechanics in Modern Construction. Earthworks Today, 12(2), 34-49.

- Taylor, R. (2022). Urban Construction Challenges and Solutions. City Planning Quarterly, 30(1), 112-128.

- Garcia, M. et al. (2019). Excavator Attachments: A Comprehensive Guide. Heavy Equipment Review, 8(4), 56-71.

YOU MAY LIKE

VIEW MOREExcavator High Reach Demolition Arm

VIEW MOREExcavator High Reach Demolition Arm VIEW MOREExcavator High Frequency Screening Bucket

VIEW MOREExcavator High Frequency Screening Bucket VIEW MOREUnloading Train Excavator Long Legs

VIEW MOREUnloading Train Excavator Long Legs VIEW MORESeaside Excavator Heightening Column

VIEW MORESeaside Excavator Heightening Column VIEW MORERailway excavator dustpan bucket

VIEW MORERailway excavator dustpan bucket VIEW MORETruck Anti-Skid Track

VIEW MORETruck Anti-Skid Track VIEW MOREExcavator Vibratory Compactor

VIEW MOREExcavator Vibratory Compactor VIEW MOREExcavator Brush Cutter

VIEW MOREExcavator Brush Cutter