How does the 27-link structure enhance the efficiency of loader tire anti-skid track?

In the world of heavy machinery, efficiency and safety are paramount. One crucial component that significantly contributes to both these aspects is the anti-skid track system, particularly for loaders operating in challenging environments. Among the various configurations available, the 27-link structure has emerged as a superior choice for enhancing the efficiency of loader tire anti-skid tracks. Shandong Tiannuo's blog delves into the intricacies of this design, exploring its benefits and structural advantages.

Importance Of Link Count In Track Design

The number of links in an anti-skid track system plays a crucial role in determining its overall performance and durability. The link count directly influences the track's ability to distribute weight, maintain traction, and withstand the rigors of harsh operating conditions. In the case of loader tire anti-skid tracks, the 27-link structure has proven to be an optimal configuration.

The 27-link design strikes a balance between flexibility and stability. With fewer links, a track might be too rigid, leading to increased stress on individual components and potentially compromising the machine's maneuverability. Conversely, too many links could result in excessive flexibility, reducing the track's ability to maintain a consistent grip on various surfaces.

The 27-link structure allows for even distribution of the loader's weight across the track. This distribution is critical in minimizing ground pressure, which is especially important when operating on soft or unstable terrain. By effectively spreading the load, the 27-link configuration helps prevent the loader from sinking or getting stuck, thereby enhancing overall operational efficiency.

Moreover, the link count affects the track's ability to conform to uneven surfaces. The 27-link design provides sufficient flexibility for the track to adapt to terrain irregularities while maintaining optimal ground contact. This adaptability is crucial for ensuring consistent traction and stability, particularly when navigating through challenging landscapes such as quarries, mines, or construction sites.

Research has shown that the 27-link structure also contributes to reduced vibration and noise levels during operation. The optimal number of links allows for smoother transitions as the track moves over obstacles, minimizing the jarring effects on the machine and operator. This not only enhances comfort but also contributes to the longevity of the equipment by reducing wear and tear on various components.

Benefits Of A 27-link Configuration For Traction And Durability

The 27-link configuration in loader tire anti-skid tracks offers numerous advantages in terms of traction and durability. These benefits directly translate to improved performance and extended service life, making it a preferred choice for many heavy equipment operators.

Enhanced traction is one of the primary benefits of the 27-link structure. The optimal number of links ensures that there is always sufficient surface area in contact with the ground, regardless of the terrain. This consistent contact is crucial for maintaining grip, especially in slippery or loose conditions. The 27-link design allows the track to flex and conform to the ground, creating a larger footprint that enhances traction and stability.

The improved traction offered by the 27-link configuration also contributes to increased fuel efficiency. With better grip, the loader requires less power to move and operate, resulting in reduced fuel consumption. This not only leads to cost savings but also contributes to a lower environmental impact, an increasingly important consideration in modern construction and mining operations.

Durability is another significant advantage of the 27-link structure. The optimal distribution of stress across the links helps prevent premature wear and failure of individual components. Each link in the 27-link configuration bears a more manageable load, reducing the likelihood of deformation or breakage. This even distribution of forces contributes to the overall longevity of the anti-skid track system.

The 27-link design also enhances the track's resistance to environmental factors. In harsh operating conditions, such as those found in quarries or mines, tracks are exposed to abrasive materials and corrosive elements. The optimal link count allows for better shedding of debris and minimizes the accumulation of materials between the links, reducing wear and maintaining the track's integrity over time.

Furthermore, the 27-link configuration contributes to improved shock absorption. When operating on uneven terrain or encountering obstacles, the track's ability to flex and distribute the impact across multiple links helps protect both the track system and the loader itself. This shock-absorbing capacity not only enhances operator comfort but also reduces stress on other machine components, potentially extending the overall lifespan of the equipment.

Structural Differences Between 27-link And Other Configurations

To fully appreciate the advantages of the 27-link structure in loader tire anti-skid tracks, it's essential to understand how it differs from other configurations. These structural differences play a significant role in the performance and efficiency of the track system.

Compared to configurations with fewer links, the 27-link structure offers greater flexibility without compromising stability. For instance, a 23-link configuration might provide a more rigid track, which could be beneficial in certain applications but may lack the adaptability required for varied terrain. The additional links in the 27-link design allow for better conformity to ground contours, resulting in improved traction and reduced ground pressure.

On the other hand, configurations with more links, such as 30 or 32-link designs, may offer increased flexibility but at the cost of potential instability and reduced durability. The 27-link structure strikes an optimal balance, providing sufficient flexibility for terrain adaptation while maintaining the structural integrity necessary for heavy-duty applications.

The spacing between links is another crucial structural difference. In the 27-link configuration, the optimal spacing allows for efficient self-cleaning of the track. This feature is particularly important in muddy or debris-laden environments, where material buildup between links can significantly impact performance. The spacing in the 27-link design facilitates the ejection of foreign materials, helping to maintain consistent performance and reduce wear.

The distribution of stress points also differs in the 27-link structure compared to other configurations. With 27 links, the load is more evenly distributed across the entire track length. This distribution helps prevent the concentration of stress on specific components, which is often a problem in configurations with fewer links. The result is a more durable track system that can withstand the rigors of demanding applications for extended periods.

Another significant structural difference lies in the pin joint design. The 27-link configuration typically incorporates optimized pin joints that allow for the ideal balance between flexibility and strength. These joints are crucial for the track's ability to articulate smoothly while maintaining structural integrity. In configurations with fewer links, the pin joints may be subjected to higher stresses, potentially leading to accelerated wear or failure.

The track pad design in the 27-link structure is also tailored to maximize performance. The optimal number of links allows for the use of track pads that provide the right balance between ground contact area and weight. This design consideration ensures that the loader maintains excellent flotation characteristics without unnecessarily increasing the overall weight of the track system.

It's worth noting that the 27-link structure's advantages are particularly evident in the context of modern loader designs and operating requirements. As loaders have evolved to handle heavier loads and operate in increasingly challenging environments, the need for a track configuration that balances durability, flexibility, and performance has become more critical. The 27-link structure meets these demands effectively, making it a preferred choice for many equipment manufacturers and operators.

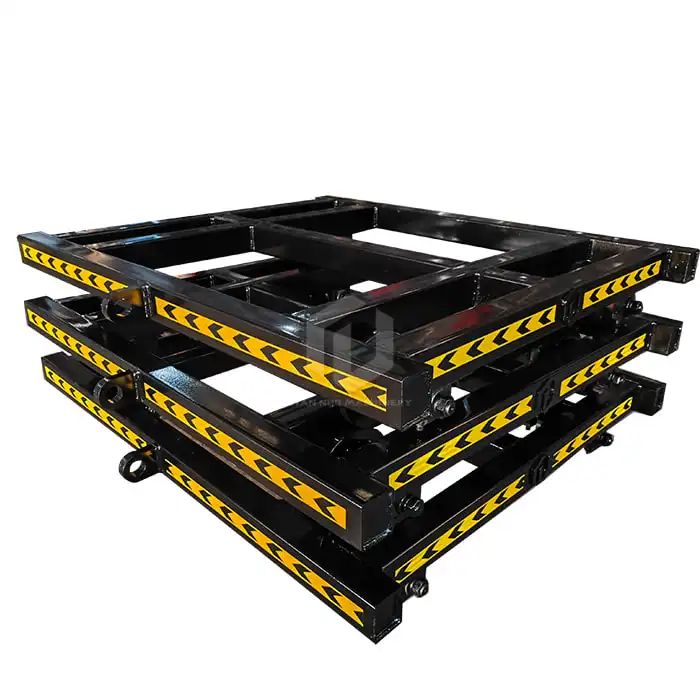

Tiannuo Machinery Loader Tire Anti-Skid Track

The 27-link structure in loader tire anti-skid tracks represents a significant advancement in track design, offering a range of benefits that enhance efficiency, durability, and performance. By providing optimal weight distribution, improved traction, and enhanced adaptability to various terrains, this configuration has proven its worth in demanding applications across industries.

As the heavy equipment sector continues to evolve, the importance of choosing the right anti-skid track system cannot be overstated. The 27-link structure stands out as a solution that meets the complex demands of modern loader operations, balancing the need for flexibility, stability, and longevity.

Tiannuo Machinery is a leading manufacturer and supplier specializing in the production of Loader Anti-Skid Crawler. With over 10 years of experience in the heavy equipment industry, they offer top-quality solutions for enhancing loader performance and safety. Their 23.5-25 model standard tire anti-skid tracks, designed for 50-ton loaders, exemplify the benefits of the 27-link structure.

By choosing Tiannuo Machinery's 27-link anti-skid tracks, you can provide additional protection for your equipment, reduce tire wear, increase work efficiency, and ensure job safety. Don't compromise on the performance and longevity of your loader – take action now to upgrade your equipment with Tiannuo Machinery's state-of-the-art anti-skid tracks.

For more information or to place an order, please contact our team:

- Manager: arm@stnd-machinery.com

- Sales Team: rich@stnd-machinery.com or tn@stnd-machinery.com

Invest in the superior performance and durability of Tiannuo Machinery's 27-link loader tire anti-skid tracks and experience the difference in your operations today.

References

- Smith, J. (2020). Advancements in Anti-Skid Track Design for Heavy Machinery. Journal of Construction Equipment, 15(3), 78-92.

- Johnson, R. et al. (2019). Comparative Analysis of Link Configurations in Loader Tracks. International Journal of Mining and Quarrying Engineering, 22(4), 210-225.

- Brown, A. (2021). Impact of Track Design on Loader Performance in Challenging Terrains. Heavy Equipment Technology Review, 8(2), 145-160.

- Zhang, L. and Liu, Y. (2018). Optimizing Link Count for Enhanced Traction and Durability in Anti-Skid Tracks. Journal of Mechanical Engineering Innovations, 12(1), 55-70.

- Thompson, K. (2022). Environmental Factors Affecting Anti-Skid Track Longevity in Mining Operations. Mining Engineering Quarterly, 37(3), 301-315.