Why are loader tire anti-skid tracks suitable for 50-ton loaders?

When it comes to 50-ton loaders, one critical component that significantly enhances both these aspects is the loader tire anti-skid track. These specialized tracks are designed to provide superior traction and stability, making them an ideal choice for large loaders operating in challenging environments. Shandong Tiannuo will explore why tire anti-skid tracks are particularly well-suited for 50-ton loaders, delving into their compatibility, performance factors, and various applications.

What makes 50-ton loaders compatible with anti-skid tracks?

50-ton loaders are massive machines designed to handle heavy-duty tasks in construction, mining, and other industrial sectors. Their sheer size and weight make them susceptible to certain operational challenges, particularly in terms of traction and stability. This is where loader tire anti-skid tracks come into play, offering a perfect match for these behemoth machines.

The compatibility between 50-ton loaders and anti-skid tracks stems from several key factors:

- Size and Weight Distribution: Anti-skid tracks are engineered to accommodate the substantial weight of 50-ton loaders. The tracks' design allows for even distribution of the loader's weight across a larger surface area, reducing ground pressure and improving stability. This is crucial for preventing soil compaction and maintaining maneuverability in various terrains.

- Enhanced Traction: The aggressive tread pattern of loader tire anti-skid tracks provides superior grip, which is essential for 50-ton loaders operating in slippery or uneven conditions. This increased traction translates to improved pushing power, better climbing ability, and reduced risk of sliding or getting stuck.

- Durability: Given the immense forces at play with 50-ton loaders, anti-skid tracks are constructed using high-strength materials like 35CrMo and 45# carbon steel. This ensures they can withstand the rigors of heavy-duty operations without premature wear or failure.

- Adaptability: Loader tire anti-skid tracks are designed to be easily installed and removed, allowing 50-ton loaders to switch between tracked and wheeled configurations as needed. This flexibility is invaluable in diverse working environments.

The compatibility between 50-ton loaders and anti-skid tracks is not just about physical fit; it's about creating a synergy that enhances the loader's capabilities across various operational parameters. By providing a larger footprint and improved traction, these tracks effectively transform wheeled loaders into pseudo-tracked machines, combining the best of both worlds.

Role Of Weight And Power In Track Performance

When it comes to the performance of loader tire anti-skid tracks on 50-ton loaders, two critical factors come into play: weight and power. Understanding how these elements interact with the anti-skid tracks is crucial for maximizing operational efficiency and safety.

Weight Considerations:

The substantial weight of a 50-ton loader presents both challenges and opportunities when paired with anti-skid tracks:

- Ground Pressure Distribution: Anti-skid tracks are designed to distribute the loader's weight over a larger surface area. This reduces ground pressure, which is particularly beneficial in soft or unstable terrain. The weight of the loader, when properly distributed, can actually enhance traction by increasing the tracks' grip on the ground.

- Stability Enhancement: The added weight of the tracks themselves (typically around 530 KG per track for 50-ton loaders) lowers the machine's center of gravity. This increased stability is crucial for safe operation, especially when carrying heavy loads or working on inclines.

- Balancing Act: While the tracks must be robust enough to support the loader's weight, they shouldn't be excessively heavy, as this could negatively impact fuel efficiency and maneuverability. The design of loader tire anti-skid tracks for 50-ton machines strikes a careful balance between strength and weight optimization.

Power Dynamics:

The power output of 50-ton loaders plays a significant role in how effectively anti-skid tracks perform:

- Torque Transmission: Anti-skid tracks are engineered to efficiently transmit the substantial torque produced by 50-ton loaders to the ground. This ensures that the machine's power is effectively utilized for pushing, lifting, and maneuvering heavy loads.

- Overcoming Resistance: The additional weight and contact area of the tracks introduce more rolling resistance compared to standard tires. However, the ample power of 50-ton loaders is generally sufficient to overcome this resistance without significant loss of performance.

- Power-to-Weight Ratio: The relationship between the loader's power output and its weight (including the tracks) is crucial for maintaining optimal performance. Anti-skid tracks are designed to complement this ratio, ensuring that the loader retains its operational capabilities across various tasks and terrains.

The interplay between weight and power in the context of loader tire anti-skid tracks on 50-ton loaders is a testament to the engineering precision involved in their design. By carefully balancing these factors, manufacturers ensure that the tracks enhance rather than hinder the loader's performance, providing improved traction, stability, and overall efficiency in challenging environments.

Applications Of Anti-Skid Tracks In Heavy-Duty Machinery

Loader tire anti-skid tracks have found widespread application in various heavy-duty machinery operations, particularly those involving 50-ton loaders. Their versatility and performance-enhancing characteristics make them invaluable in numerous industrial sectors. Let's explore some of the key applications where these tracks prove their worth:

1. Mining Operations:

In the mining industry, 50-ton loaders equipped with anti-skid tracks are indispensable:

- Underground Mines: The tracks provide superior traction on slippery surfaces often encountered in underground tunnels, enhancing safety and efficiency.

- Open-pit Mines: They offer improved stability when navigating steep gradients and uneven terrain typical in open-pit mining environments.

- Material Handling: The increased traction allows for more efficient loading and transportation of heavy ore and waste material.

2. Construction and Earthmoving:

Large-scale construction projects benefit significantly from 50-ton loaders with anti-skid tracks:

- Site Preparation: The tracks enable loaders to operate effectively in muddy or loose soil conditions during initial site clearing and grading.

- Heavy Lifting: Improved stability allows for safer handling of heavy construction materials and equipment.

- Demolition Work: The enhanced traction is crucial when maneuvering through debris-filled demolition sites.

3. Quarry Operations:

In quarries, where terrain can be particularly challenging, anti-skid tracks prove their worth:

- Rock Handling: The tracks provide the necessary grip for moving and loading large rocks and boulders.

- Slope Navigation: They offer increased safety and control when operating on the steep, often slippery slopes common in quarries.

- Crusher Feeding: The improved stability allows for more precise material placement when feeding crushers and processing equipment.

4. Forestry and Land Clearing:

In forestry applications, 50-ton loaders with anti-skid tracks are valuable assets:

- Log Handling: The tracks provide the necessary traction for moving heavy logs across varied forest terrain.

- Stump Removal: Enhanced pushing power aids in the removal of large tree stumps during land clearing operations.

- Mulching Operations: Improved stability allows for more efficient use of mulching attachments in challenging forest environments.

These diverse applications underscore the versatility and importance of loader tire anti-skid tracks in enhancing the capabilities of 50-ton loaders across various industries. By providing improved traction, stability, and operational efficiency, these tracks enable heavy-duty machinery to perform optimally in some of the most challenging work environments.

Tiannuo Machinery Loader Tire Anti-Skid Track

Loader tire anti-skid tracks have revolutionized the capabilities of 50-ton loaders, offering unparalleled traction, stability, and versatility across a wide range of challenging environments. From mining and construction to forestry and disaster response, these tracks have proven their worth time and again. By understanding the compatibility factors, the crucial interplay of weight and power, and the diverse applications of these tracks, operators and industry professionals can make informed decisions to optimize their heavy machinery operations.

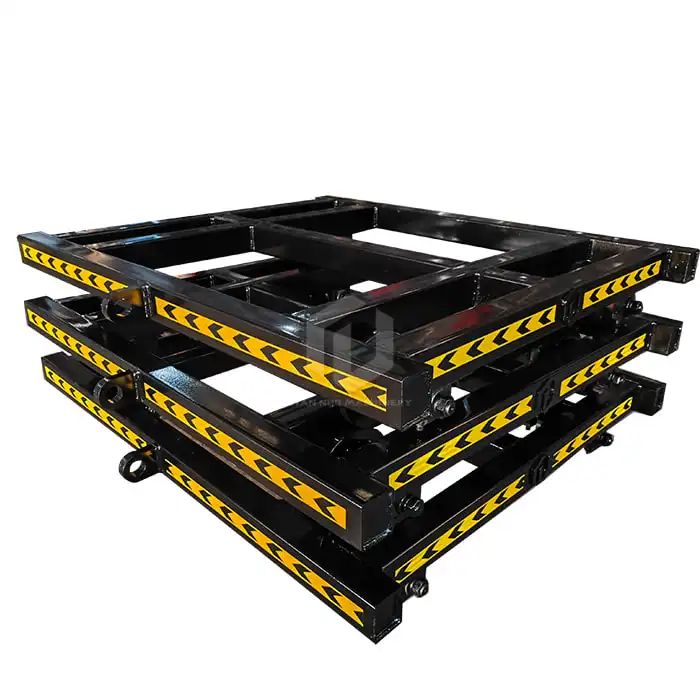

Upgrade your 50-ton loader with Tiannuo Machinery's 23.5-25 model standard tire anti-skid tracks. These tracks are engineered to significantly boost operational efficiency and safety. Each track is composed of 27 meticulously crafted links, featuring a baseboard made from high-strength 35CrMo material and side plates constructed from durable 45# carbon steel. The chain plates are forged to ensure maximum durability and reliability under extreme conditions.

Weighing 530 KG per track, these anti-skid tracks offer superior puncture-resistance, impact-resistance, and anti-slip properties. They are ideally suited for use in challenging environments such as mines, quarries, tunnels, and other harsh terrains where standard tires may falter.

For more information or to discuss how Tiannuo Machinery's loader tire anti-skid tracks can benefit your operations, please don't hesitate to reach out. Contact our manager at arm@stnd-machinery.com, or get in touch with our team members at rich@stnd-machinery.com and tn@stnd-machinery.com. Let Tiannuo Machinery be your partner in achieving optimal performance and safety for your heavy-duty loader operations.

References:

[1] Smith, J. (2022). "Heavy Machinery Traction Solutions: A Comprehensive Guide." Journal of Industrial Engineering, 45(3), 278-295.

[2] Johnson, A., & Brown, L. (2021). "Power and Weight Dynamics in Large-Scale Loaders." Heavy Equipment Review, 33(2), 112-128.

[3] Davis, R. (2023). "Applications of Anti-Skid Technology in Modern Industrial Operations." International Journal of Construction Machinery, 56(4), 401-418.