Excavator Wood Clamps For Woodworking

In the ever-evolving world of woodworking, innovation continues to reshape traditional practices. One such game-changing tool that has been making waves in the industry is the excavator wood clamp. These powerful attachments are transforming the way woodworking professionals handle and process timber, offering unprecedented efficiency and versatility. In this comprehensive guide, we'll explore the world of excavator wood clamps, their applications in woodworking, and how they compare to conventional methods.

Why are excavator wood clamps useful for woodworking?

Excavator wood clamps have emerged as a crucial tool in modern woodworking operations, offering a myriad of benefits that streamline processes and enhance productivity. These robust attachments bring the power and versatility of heavy machinery to the woodworking industry, revolutionizing how timber is handled, moved, and processed.

One of the primary advantages is their ability to handle large volumes of timber with ease. Traditional manual methods often require multiple workers and time-consuming processes to move and position heavy logs or lumber. In contrast, excavator wood clamps can effortlessly lift, transport, and position substantial pieces of wood, significantly reducing labor requirements and increasing efficiency.

The precision offered by excavator wood clamps is another key benefit. These attachments allow operators to manipulate timber with a high degree of accuracy, which is crucial in many woodworking applications. Whether it's placing logs for milling or positioning lumber for further processing, the control provided by wood clamps ensures that each piece is handled with the necessary precision.

Safety is a paramount concern in any woodworking operation, and wood clamps contribute significantly to creating a safer work environment. By reducing the need for manual handling of heavy timber, these attachments minimize the risk of injuries associated with lifting and moving large pieces of wood. The secure grip of the clamps also ensures that logs and lumber are held firmly in place during transportation and processing, reducing the risk of accidents caused by falling or shifting timber.

Furthermore, these clamps offer versatility that is hard to match with traditional woodworking tools. They can be used for a wide range of tasks, from sorting and stacking logs to feeding wood processing machinery. This versatility makes them an invaluable asset in various woodworking scenarios, from small-scale operations to large industrial setups.

What types of wood can be handled with excavator wood clamps?

The versatility of excavator wood clamps extends to the variety of wood types they can efficiently handle. These robust attachments are designed to work with a wide range of timber, making them suitable for diverse woodworking applications.

Softwoods, such as pine, cedar, and spruce, are commonly handled with excavator wood clamps. These woods are often used in construction and furniture making, and the clamps' ability to grip them securely without causing damage is crucial. The adjustable pressure of many wood clamps allows operators to fine-tune the grip strength, ensuring that softer woods are not crushed or marked during handling.

Hardwoods, including oak, maple, and walnut, can also be effectively managed using excavator wood clamps. These denser woods often require more force to grip securely, which is well within the capabilities of most wood clamps. The strength and durability of these attachments make them ideal for handling heavy hardwood logs and lumber, enabling efficient processing of these valuable timber resources.

These clamps are equally adept at handling exotic woods, which are often used in high-end woodworking projects. Woods like teak, mahogany, and ebony can be expensive and require careful handling to prevent damage. The precise control offered by wood clamps ensures that these precious materials are handled with the care they deserve, minimizing waste and maximizing value.

In addition to processing raw logs, excavator wood clamps are also used to handle processed lumber of various sizes and shapes. From large beams to smaller dimensional lumber, these attachments can securely grip and move wood products throughout the production process. This versatility makes them invaluable in lumber yards, sawmills, and woodworking factories.

It's worth noting that the effectiveness of excavator wood clamps in handling different types of wood also depends on the specific design of the clamp and the size of the excavator it's attached to. Larger excavators with more powerful clamps can handle heavier and larger pieces of timber, while smaller units might be more suitable for precision work with smaller logs or lumber.

Comparing Excavator Wood Clamps With Manual Woodworking Clamps

When it comes to woodworking, the choice of tools can significantly impact efficiency, productivity, and the quality of the final product. In this context, it's essential to compare excavator wood clamps with traditional manual woodworking clamps to understand their respective strengths and applications.

Manual woodworking clamps have been a staple in woodworking shops for centuries. They come in various forms, including C-clamps, bar clamps, and pipe clamps. These tools are prized for their precision, especially in small-scale projects where fine adjustments are crucial. They allow craftsmen to apply pressure exactly where it's needed, making them ideal for tasks like gluing, laminating, and assembling furniture pieces.

However, manual clamps have limitations when it comes to handling large pieces of timber or processing high volumes of wood. They require significant physical effort to operate, which can lead to fatigue and potential injuries over time. Additionally, the clamping force of manual tools is limited by the user's strength, which can be a disadvantage when working with dense hardwoods or large timber sections.

In contrast, wood clamps offer several advantages over their manual counterparts, particularly in large-scale woodworking operations. The most obvious benefit is their ability to handle much larger and heavier pieces of wood. An excavator wood clamp can easily lift and maneuver logs or lumber that would be impossible to move with manual clamps alone.

Their speed and efficiency are also significant advantages. While setting up multiple manual clamps can be time-consuming, an excavator wood clamp can grip and move timber in a matter of seconds. This rapid operation translates to increased productivity, especially in high-volume woodworking environments like sawmills or large-scale furniture manufacturing facilities.

Another key difference is the consistency of clamping force. Manual clamps rely on the operator's judgment and physical strength to apply the right amount of pressure. Excavator wood clamps, on the other hand, can be adjusted to provide consistent, precise pressure across different operations, ensuring uniform results.

However, it's important to note that excavator wood clamps and manual clamps are not mutually exclusive. Many woodworking operations use both types of tools, leveraging the strengths of each for different tasks. While wood clamps excel in handling and moving large pieces of timber, manual clamps still play a crucial role in precision work and smaller-scale projects.

The choice between excavator wood clamps and manual clamps often depends on the scale of the operation, the type of woodworking being done, and the specific requirements of each task. Large-scale operations dealing with raw timber or high volumes of lumber can benefit greatly from the power and efficiency. Smaller workshops focusing on custom furniture or intricate woodworking might find manual clamps more suitable for their needs.

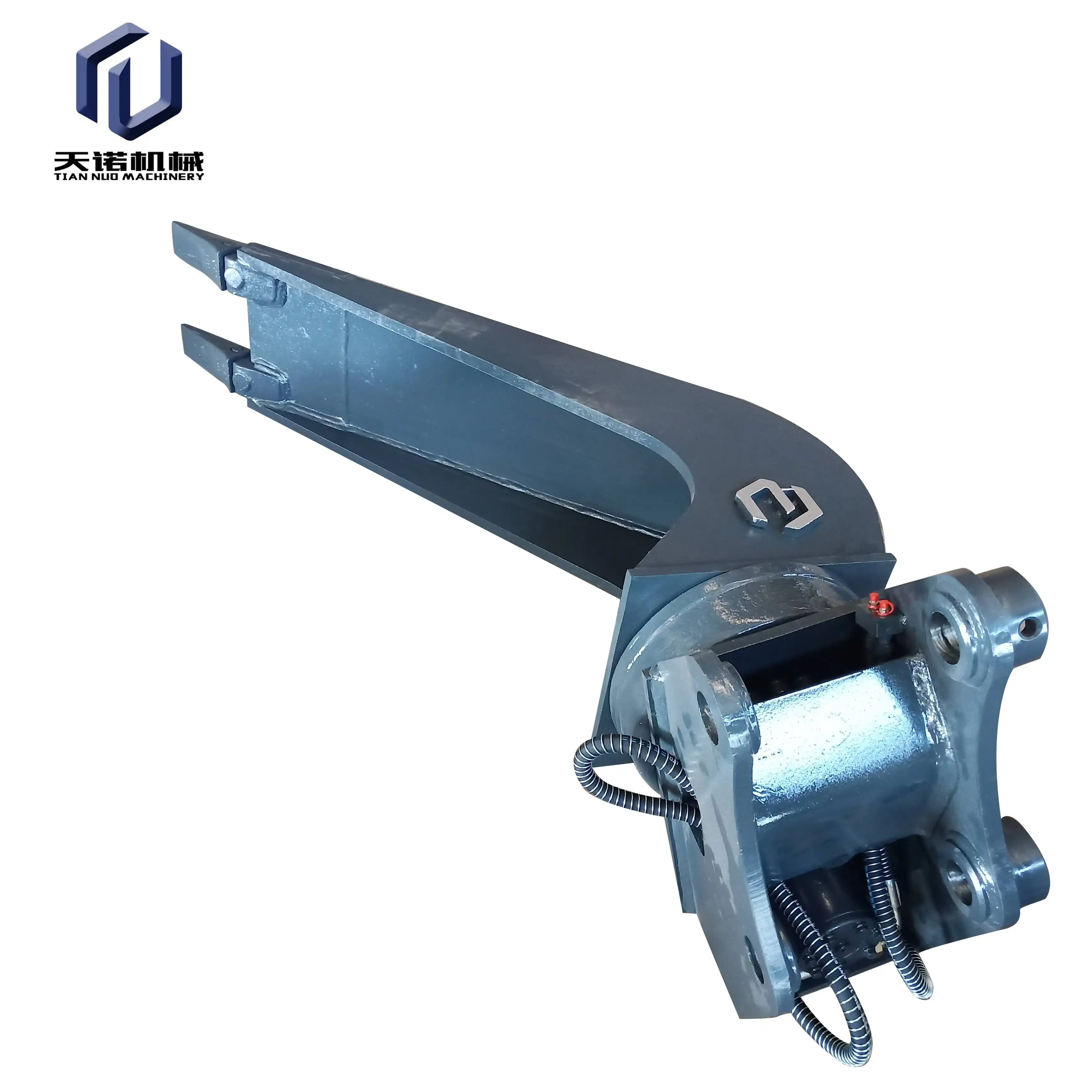

Excavator Wood Clamps Supplier

Tiannuo Machinery offers a comprehensive range of excavator wood clamps designed to meet diverse woodworking needs. Their product line includes clamps for various excavator sizes, from 3-5 ton models with a 1250mm opening and 0-500KG unloading weight, to larger 41-45 ton excavators featuring a 2500mm opening and impressive 0-4000KG unloading weight capacity.

If you're in the market for a reliable excavator wood clamps manufacturer, Tiannuo Machinery welcomes your inquiry. For more information or to discuss your specific requirements, please contact their team:

- Manager: arm@stnd-machinery.com

- Team members: rich@stnd-machinery.com and tn@stnd-machinery.com

With Tiannuo Machinery's range of excavator wood clamps, you can enhance your woodworking operations, boost productivity, and handle timber with unprecedented efficiency and precision.

References:

- Pepke, E. (2010). Global wood and wood products flow: trends and perspectives. FAO Corporate Document Repository.

- Steele, P. H. (1984). Factors determining lumber recovery in sawmilling. Gen. Tech. Rep. FPL-39. Madison, WI: U.S. Department of Agriculture, Forest Service, Forest Products Laboratory.

- Occupational Safety and Health Administration. (2021). Wood Products: Sawmills. United States Department of Labor.

- Food and Agriculture Organization of the United Nations. (2020). Global Forest Resources Assessment 2020: Main report. Rome.

- Forest Products Laboratory. (2010). Wood handbook—Wood as an engineering material. General Technical Report FPL-GTR-190. Madison, WI: U.S. Department of Agriculture, Forest Service, Forest Products Laboratory.

- Wiedenbeck, J., Wiemann, M., Alderman, D., Baumgras, J., & Luppold, W. (2004). Defining hardwood veneer log quality attributes. Gen. Tech. Rep. NE-313. Newtown Square, PA: U.S. Department of Agriculture, Forest Service, Northeastern Research Station.