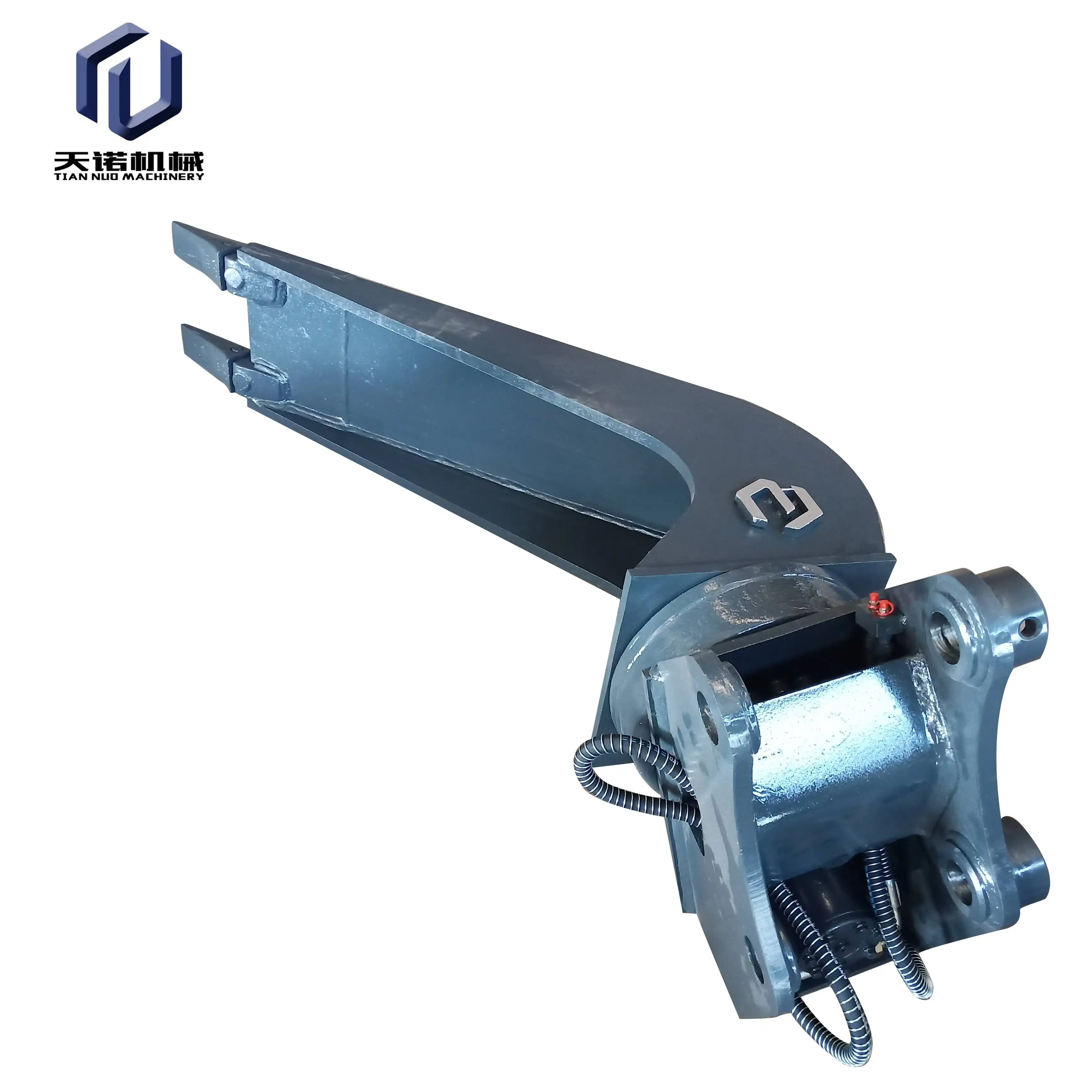

Excavator High Reach Demolition Long Boom And Arm For Sale

In the world of construction and demolition, efficiency and precision are paramount. One of the most innovative tools in this field is the excavator high reach demolition long boom and arm. This specialized equipment has revolutionized the way we approach demolition projects, especially those involving tall structures. In this comprehensive guide, we'll explore the key factors to consider when purchasing a high reach demolition long boom and arm, how to choose the right one for your excavator, and the ways it can improve operational efficiency.

What factors should you consider before buying a high reach demolition long boom and arm?

Investing in an excavator high reach demolition long boom and arm is a significant decision that requires careful consideration. Here are the key factors you should evaluate before making your purchase:

1. Project Requirements

First and foremost, assess the specific needs of your projects. Consider the following questions:

- What is the maximum height you need to reach?

- What type of materials will you be demolishing?

- What are the typical site conditions you'll be working in?

Understanding your project requirements will help you determine the appropriate reach, strength, and features needed in your high reach demolition equipment.

2. Compatibility with Existing Equipment

Ensure that the high reach demolition long boom and arm you're considering is compatible with your existing excavator. Factors to consider include:

- The excavator's weight class and hydraulic capacity

- Attachment mounting systems

- Control systems and hydraulic connections

Compatibility is crucial for optimal performance and safety. Consulting with the manufacturer or a qualified dealer can help you determine the best match for your excavator.

3. Build Quality and Durability

High reach demolition work puts significant stress on equipment. Look for a long boom and arm constructed with high-quality materials, such as high-strength steel, to ensure durability and longevity. Key aspects to consider include:

- Material composition and thickness

- Welding quality

- Reinforcement in high-stress areas

- Protective coatings to prevent corrosion

Investing in a well-built, durable boom and arm will pay off in the long run through reduced maintenance costs and increased uptime.

4. Safety Features

Safety should always be a top priority in demolition work. Look for high reach demolition long booms and arms that incorporate advanced safety features, such as:

- Overload warning systems

- Automatic shut-off mechanisms

- Improved visibility features

- Stabilization systems

These safety features not only protect your workers but also help prevent equipment damage and project delays.

5. Versatility and Attachments

Consider the range of attachments compatible with the high reach demolition long boom and arm. A versatile system that can accommodate various tools such as crushers, shears, and grapples will increase the equipment's utility across different projects.

6. After-Sales Support and Warranty

Lastly, evaluate the manufacturer's after-sales support and warranty offerings. Look for:

- Comprehensive warranty coverage

- Availability of spare parts

- Access to technical support and training

- Maintenance and repair services

Good after-sales support can significantly reduce downtime and extend the lifespan of your equipment.

By carefully considering these factors, you can make an informed decision when purchasing a high reach demolition long boom and arm, ensuring you get equipment that meets your needs and provides long-term value.

How to choose the right high reach demolition boom for your excavator?

Selecting the appropriate excavator high reach demolition long boom and arm for your excavator is crucial for maximizing efficiency and safety on the job site. Here's a detailed guide to help you make the right choice:

1. Assess Your Excavator's Specifications

Start by thoroughly understanding your excavator's capabilities:

- Weight class

- Hydraulic flow and pressure ratings

- Lifting capacity

- Stability ratings

These specifications will determine the size and type of high reach demolition boom your excavator can safely and effectively operate.

2. Determine Required Reach and Working Height

Consider the typical projects you undertake or plan to pursue:

- What is the maximum height of structures you need to demolish?

- What is the required horizontal reach for safe and efficient operation?

Choose a boom that provides adequate reach for your projects while ensuring your excavator can handle the extended length safely.

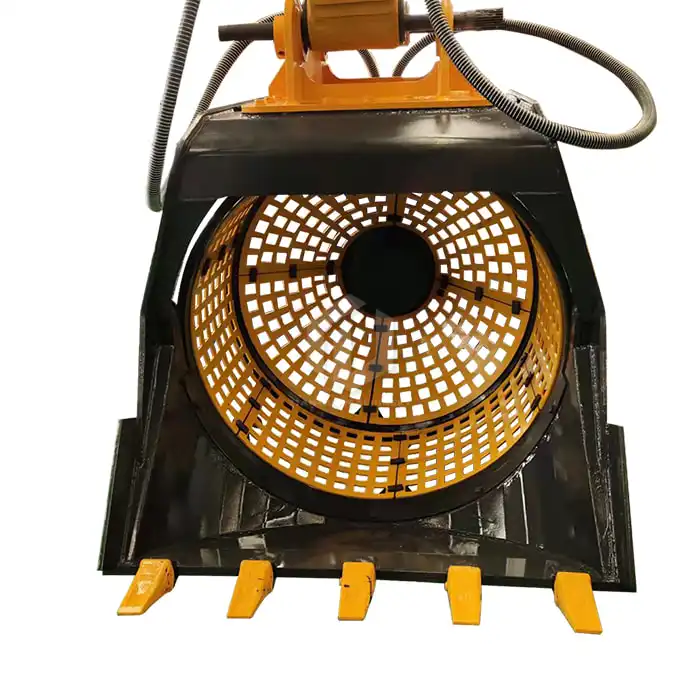

3. Consider the Types of Attachments

Different demolition tasks require various attachments. Ensure the boom you choose is compatible with the attachments you need, such as:

- Hydraulic crushers

- Demolition shears

- Grapples

- Hydraulic hammers

The boom should be able to handle the weight and operational requirements of these attachments.

4. Evaluate Boom Design and Features

Look for design features that enhance performance and safety:

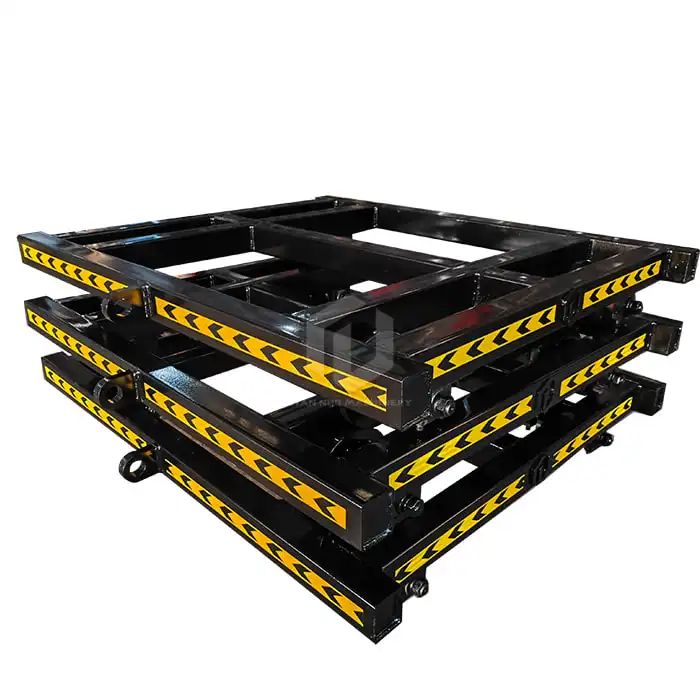

- Modular design for easy transportation and setup

- Quick-change systems for attachments

- Built-in safety systems like overload warnings

- Reinforced structure in high-stress areas

Advanced features can significantly improve operational efficiency and reduce downtime.

5. Consider Transportation and Setup

Think about how you'll transport the high reach demolition boom between job sites:

- Does it break down into manageable sections for transport?

- How complex is the assembly and disassembly process?

- What equipment is needed for setup?

Easier transportation and setup can save time and reduce logistics costs.

6. Consult with Manufacturers and Experts

Don't hesitate to seek advice from manufacturers, dealers, or experienced operators. They can provide valuable insights into:

- Compatibility issues

- Performance in real-world conditions

- Common challenges and solutions

- Maintenance requirements

Their expertise can help you avoid potential pitfalls and make a more informed decision.

7. Consider Future Needs

While it's important to meet your current requirements, also think about your future projects:

- Are you likely to take on larger demolition projects in the future?

- Might you need additional reach or capacity?

Choosing a boom with some room for growth can be a wise long-term investment.

By carefully considering these factors and conducting thorough research, you can select a high reach demolition boom that perfectly complements your excavator and meets your operational needs. Remember, the right equipment not only improves efficiency but also enhances safety and profitability in your demolition projects.

How does a high reach demolition long boom improve operational efficiency?

High reach demolition long booms have revolutionized the demolition industry, significantly enhancing operational efficiency in numerous ways. Let's explore how these specialized attachments contribute to improved productivity and cost-effectiveness on demolition sites.

1. Increased Vertical Reach

The primary advantage of a high reach demolition long boom is its ability to extend the vertical reach of an excavator:

- Allows for the demolition of taller structures without the need for explosives

- Reduces the need for scaffolding or cranes in many scenarios

- Enables precise demolition at heights that were previously challenging to access

This increased reach translates to fewer equipment moves and faster project completion times.

2. Enhanced Safety

Safety improvements directly contribute to operational efficiency:

- Operators can work from a safe distance, reducing risks associated with falling debris

- Minimizes the need for workers to be in high-risk areas of the demolition site

- Reduces the likelihood of accidents, which can cause project delays and increased costs

A safer work environment leads to fewer interruptions and a more efficient workflow.

3. Precision and Control

High reach demolition long booms offer improved precision in demolition work:

- Allows for selective demolition, preserving adjacent structures

- Enables more accurate placement of demolition tools, reducing unnecessary damage

- Facilitates better sorting of materials during the demolition process, aiding in recycling efforts

This precision results in less rework and more efficient use of resources.

4. Versatility in Attachments

Modern high reach demolition booms can accommodate various attachments:

- Hydraulic crushers for concrete structures

- Shears for cutting steel beams

- Grapples for material handling

- Hammers for breaking tough materials

This versatility allows for quick adaptation to different demolition tasks without changing equipment, saving time and increasing productivity.

5. Reduced Equipment and Labor Requirements

By using a high reach demolition long boom, contractors can often reduce the amount of equipment and labor needed on site:

- Fewer pieces of equipment are required to complete the job

- Reduced need for manual labor in high-risk areas

- Less time spent on equipment setup and teardown

These reductions lead to lower operational costs and improved project timelines.

6. Improved Material Processing

High reach demolition booms facilitate better on-site material processing:

- Allows for more efficient sorting of demolition waste

- Enhances the ability to separate recyclable materials

- Reduces transportation costs by processing materials on-site

This improved processing can lead to increased revenue from recycled materials and reduced disposal costs.

7. Adaptability to Different Project Types

High reach demolition long booms are adaptable to various demolition scenarios:

- Suitable for both complete and partial demolitions

- Effective in urban environments with space constraints

- Useful in industrial demolitions where precision is crucial

This adaptability allows contractors to take on a wider range of projects, increasing overall operational efficiency across their business.

8. Reduced Environmental Impact

The precision and control offered by high reach demolition booms contribute to reduced environmental impact:

- Less dust and debris dispersion due to controlled demolition

- Reduced noise pollution compared to explosive demolition methods

- More efficient sorting and recycling of materials

These environmental benefits can lead to faster project approvals and better community relations, indirectly improving operational efficiency.

In conclusion, high reach demolition long booms significantly enhance operational efficiency in demolition projects. They offer increased safety, precision, versatility, and adaptability while reducing equipment and labor requirements. By enabling contractors to work smarter and more effectively, these specialized attachments not only improve project timelines and cost-effectiveness but also contribute to more sustainable demolition practices.

Excavator High Reach Demolition Long Boom And Arm For Sale

When it comes to choosing a reliable manufacturer for your excavator high reach demolition long boom and arm, Tiannuo Machinery stands out as a leading specialist in the field. With years of expertise in producing high-quality excavator attachments, including the specialized tunnel arm designed for confined spaces, Tiannuo Machinery offers solutions that cater to the unique challenges of demolition and tunnel construction.

The tunnel-specific shortened arm, crafted from high-strength manganese steel, is engineered to withstand severe crushing environments while providing superior construction efficiency. This innovative design, coupled with the ability to equip enlarged buckets and breaker hammers, makes Tiannuo Machinery's products ideal for tackling demanding tunnel construction projects.

If you're in the market for a top-tier excavator high reach demolition long boom or specialized tunnel arm, we invite you to reach out to our experienced team. Our commitment to quality and customer satisfaction ensures that you'll receive equipment that meets the highest standards of performance and durability.

For more information or to discuss your specific needs, please contact our manager at arm@stnd-machinery.com. Alternatively, you can reach our team members at rich@stnd-machinery.com or tn@stnd-machinery.com. Let Tiannuo Machinery be your partner in elevating your demolition and construction capabilities to new heights.

References:

1. Zhang, J., & Li, X. (2020). Development and application of high-reach demolition equipment in modern construction. Construction Technology Review, 35(4), 78-92.

2. Smith, R. D., & Johnson, K. L. (2019). Safety considerations in high-reach demolition operations: A comprehensive review. Journal of Construction Safety, 12(2), 145-163.

3 . Wilson, M. A. (2021). Selection criteria for demolition equipment: Focus on high-reach boom and arm systems. International Journal of Construction Engineering, 28(3), 301-318.

4. Davis, P., & Anderson, S. (2018). Efficiency analysis of modern demolition techniques and equipment. Construction Management Research Quarterly, 24(1), 55-72.