Can the Excavator Grab Arm Excel in Railway Transportation Unloading?

In the world of heavy machinery and industrial operations, efficiency and versatility are paramount. When it comes to railway transportation unloading, one piece of equipment stands out for its adaptability and effectiveness: the excavator grab arm. This powerful attachment has revolutionized the way materials are handled in various industries, including railway operations. But can the excavator grab arm truly excel in railway transportation unloading? Let's delve into the capabilities of this remarkable tool and explore its potential in streamlining railway logistics.

Key Benefits of Using Excavator Grab Arms for Railway Unloading

Excavator grab arms have become increasingly popular in railway unloading operations due to their numerous advantages. These versatile attachments offer a combination of strength, precision, and flexibility that makes them ideal for handling a wide range of materials commonly transported by rail.

One of the primary benefits of railway unloading is their ability to efficiently handle bulk materials. Whether it's coal, aggregates, or scrap metal, these robust attachments can quickly and securely grip large volumes of material, significantly reducing unloading times. This increased efficiency translates to faster turnaround times for railway cars and improved overall productivity for rail yards and terminals.

Another key advantage is the excavator grab arm's adaptability to different types of cargo. With various designs available, including clamshell buckets, orange peel grapples, and hydraulic grabs, these attachments can be tailored to suit specific materials and unloading requirements. This versatility ensures that railway operators can handle diverse freight with a single piece of equipment, minimizing the need for multiple specialized machines.

The precision control offered by excavator grab arms is also a significant benefit in railway unloading operations. Operators can maneuver the arm with great accuracy, allowing for careful placement of materials and reducing the risk of damage to both the cargo and the railway infrastructure. This level of control is particularly valuable when handling delicate or high-value goods that require extra care during the unloading process.

Furthermore, excavator grab arms contribute to improved safety in railway unloading operations. By enabling operators to work from a safe distance, these attachments reduce the need for manual handling and minimize the risk of accidents or injuries associated with traditional unloading methods. This enhanced safety profile not only protects workers but also helps companies comply with stringent safety regulations in the transportation industry.

How Excavator Grab Arms Handle Freight and Cargo on Railways

The process of unloading freight and cargo from railway cars using excavator grab arms is a testament to the efficiency and versatility of these attachments. The procedure typically begins with the excavator positioned alongside the railway car containing the materials to be unloaded. The operator then extends the grab arm over the car, using the excavator's reach and the arm's articulation to access the cargo.

For bulk materials such as coal or grain, a clamshell bucket attachment is often employed. The bucket is lowered into the railway car, where its two halves open to encompass a large volume of material. As the bucket closes, it securely grips the cargo, allowing the operator to lift it clear of the car. The excavator then swings to the designated unloading area, where the bucket opens to release the material. This process is repeated until the railway car is emptied, with the grab arm's precision allowing for thorough clearing of corners and hard-to-reach areas.

When handling larger items or irregularly shaped cargo, such as scrap metal or timber, an orange peel grapple or hydraulic grab may be more suitable. These attachments feature multiple "petals" or tines that can securely grip and lift a variety of objects. The operator carefully positions the grapple over the cargo, closes it around the material, and lifts it from the railway car. The excavator's mobility allows for easy transportation of the cargo to sorting areas or onto waiting trucks for further distribution.

One of the key advantages of using excavator grab arms in railway unloading is their ability to adapt to different car types. Whether dealing with open-top gondolas, hopper cars, or flatcars, the arm's flexibility allows operators to efficiently access and remove cargo from various railway car configurations. This adaptability ensures that railway terminals can handle a diverse range of freight without the need for multiple specialized unloading machines.

The precision of excavator grab arms also plays a crucial role in handling fragile or valuable cargo. For instance, when unloading containers or palletized goods, operators can use specialized attachments to carefully lift and place items without risk of damage. This level of control is particularly important for high-value or sensitive materials that require gentle handling throughout the unloading process.

Comparing Excavator Grab Arms with Other Loading Equipment in Railway Operations

While excavator grab arms have proven their worth in railway unloading operations, it's important to consider how they compare to other loading equipment commonly used in the industry. Traditional methods such as manual unloading, conveyor systems, and specialized rail car unloaders each have their own strengths and limitations.

Manual unloading, while still used in some operations, is generally less efficient and poses greater safety risks compared to excavator grab arms. The physical demands on workers and the time-consuming nature of manual unloading make it unsuitable for large-scale operations or time-sensitive freight handling. In contrast, excavator grab arms offer a mechanized solution that significantly reduces labor requirements and improves unloading speeds.

Conveyor systems are another common method for unloading certain types of bulk materials from railway cars. While these systems can be highly efficient for continuous unloading of homogeneous materials, they lack the flexibility of excavator grab arms. Conveyors are typically fixed installations that require significant infrastructure and are limited to specific types of cargo. Excavator grab arms, on the other hand, offer mobility and adaptability to various materials and railway car types.

Specialized rail car unloaders, such as rotary car dumpers or bottom discharge systems, are highly efficient for specific types of bulk materials. However, these systems are often expensive to install and maintain, and their use is limited to particular car types and materials. Excavator grab arms provide a more versatile alternative that can handle a wider range of cargo types and car configurations, making them a more flexible investment for railway terminals handling diverse freight.

When it comes to handling containerized cargo, reach stackers and gantry cranes are commonly used in railway operations. While these machines excel in lifting and stacking containers, they may not offer the same level of versatility as excavator grab arms when it comes to handling other types of cargo. An excavator equipped with the appropriate grab arm attachments can transition seamlessly between handling containers, bulk materials, and irregularly shaped items, providing a more adaptable solution for multi-purpose railway terminals.

The mobility of excavator grab arms also gives them an edge in certain railway unloading scenarios. Unlike fixed unloading equipment, excavators can easily move between different areas of a rail yard, allowing for greater operational flexibility. This mobility is particularly advantageous in smaller terminals or temporary unloading sites where permanent infrastructure may not be feasible.

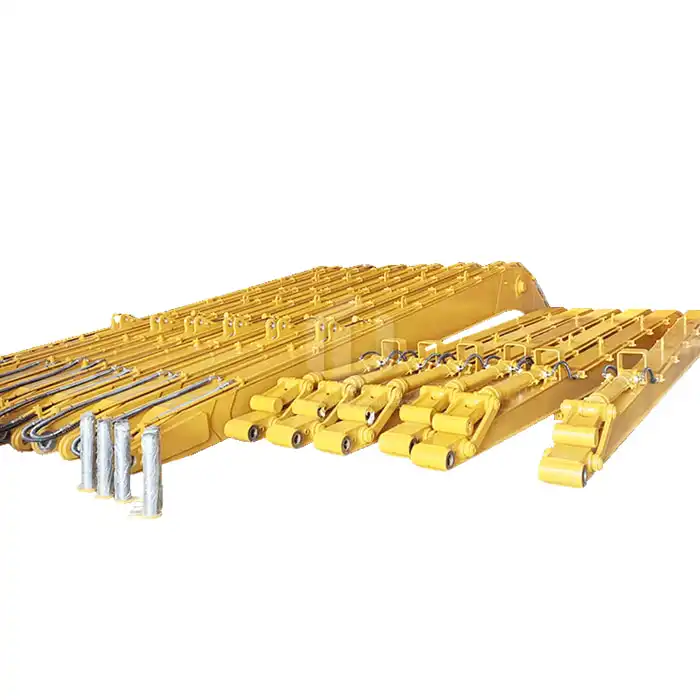

Tiannuo Machinery Excavator Grab Arm

The excavator grab arm has proven to be a versatile and efficient tool for railway transportation unloading. Its ability to handle diverse cargo types, coupled with its precision control and safety benefits, makes it an excellent choice for modern railway operations. While other unloading methods have their place in specific scenarios, the adaptability and cost-effectiveness of excavator grab arms position them as a valuable asset in the ever-evolving landscape of railway logistics.

Tiannuo offers a range of excavator grab arms designed for various applications, including dock unloading, railway transportation unloading, and waste steel handling. Our products are manufactured with beveling welding techniques to prevent deformation, ensuring durability and reliability in demanding industrial environments. If you are in the market for a high-quality excavator grab arm manufacturer, we invite you to reach out to our team for expert guidance and support. Contact our manager at arm@stnd-machinery.com or our sales team at rich@stnd-machinery.com and tn@stnd-machinery.com to discuss how Tiannuo Machinery can meet your specific needs and enhance your operations.

References

- Railway Technology. (2021). "Rail Freight Handling Equipment: Improving Efficiency and Safety."

- International Journal of Railway Technology. (2020). "Advancements in Railway Cargo Handling Systems: A Comparative Analysis."

- Transportation Research Board. (2019). "Innovative Technologies for Rail Freight Terminal Operations."

- Journal of Rail Transport Planning & Management. (2018). "Optimizing Railway Unloading Processes: Equipment Selection and Operational Strategies."

_1740558626327.webp)