Why is the excavator grab arm Ideal for Dock Unloading?

In the world of maritime logistics and port operations, efficiency is key. The ability to quickly and effectively unload ships can make a significant difference in the overall productivity of a port. This is where the excavator grab arm comes into play, revolutionizing the way we handle bulk materials at docks.

The Versatility and Efficiency of Excavator Grab Arms in Dock Operations

Excavator grab arms have emerged as a game-changer in dock unloading operations due to their remarkable versatility and efficiency. These powerful attachments are designed to handle a wide variety of bulk materials, from coal and grain to scrap metal and aggregates. The ability to switch between different types of cargo without significant downtime gives ports a competitive edge in managing diverse shipments.

One of the primary advantages of using an excavator grab arm for dock unloading is its precision and control. Operators can maneuver the arm with great accuracy, allowing for targeted material extraction from ship holds. This precision not only speeds up the unloading process but also minimizes the risk of damage to both the cargo and the vessel itself.

Moreover, grab arms are known for their impressive reach and lifting capacity. Modern designs can extend deep into ship holds, accessing areas that might be challenging for traditional unloading methods. This extended reach, combined with the ability to lift substantial loads, means fewer cycles are needed to empty a ship, significantly reducing unloading times.

Enhancing Productivity and Safety in Port Operations

The implementation of excavator grab arms in dock unloading operations has led to substantial improvements in productivity. These attachments can handle larger volumes of material per cycle compared to conventional methods, which translates to faster turnaround times for ships. Quicker unloading not only increases the port's capacity to handle more vessels but also reduces demurrage costs for shipping companies.

Safety is another crucial factor where excavator grab arms excel. By automating much of the unloading process, these attachments minimize the need for manual labor in potentially hazardous areas. Workers can operate the excavator from a safe distance, reducing the risk of accidents and injuries associated with traditional bulk material handling methods.

Furthermore, the precise control offered by grab arms helps prevent spillage and material loss during the unloading process. This not only maintains the quality and quantity of the cargo but also contributes to a cleaner, more environmentally friendly port operation. The reduction in material wastage and cleanup requirements leads to cost savings and improved environmental compliance for port authorities.

Adaptability to Various Cargo Types and Environmental Conditions

One of the standout features of excavator grab arms is their adaptability to different types of cargo and environmental conditions. Manufacturers offer a range of grab designs, each optimized for specific materials. For instance, clamshell grabs are ideal for handling loose materials like sand or gravel, while orange peel grabs are better suited for irregularly shaped items such as scrap metal.

This adaptability extends to the ability to work in various weather conditions. Unlike some traditional unloading methods that may be hindered by wind or rain, excavator grab arms can continue to operate effectively in less-than-ideal weather, ensuring that port operations can proceed with minimal interruptions.

The robustness of grab arms also makes them suitable for handling abrasive or corrosive materials. High-quality arms are constructed with wear-resistant materials and protective coatings, ensuring longevity even when dealing with challenging cargoes. This durability translates to lower maintenance costs and reduced downtime for port operators.

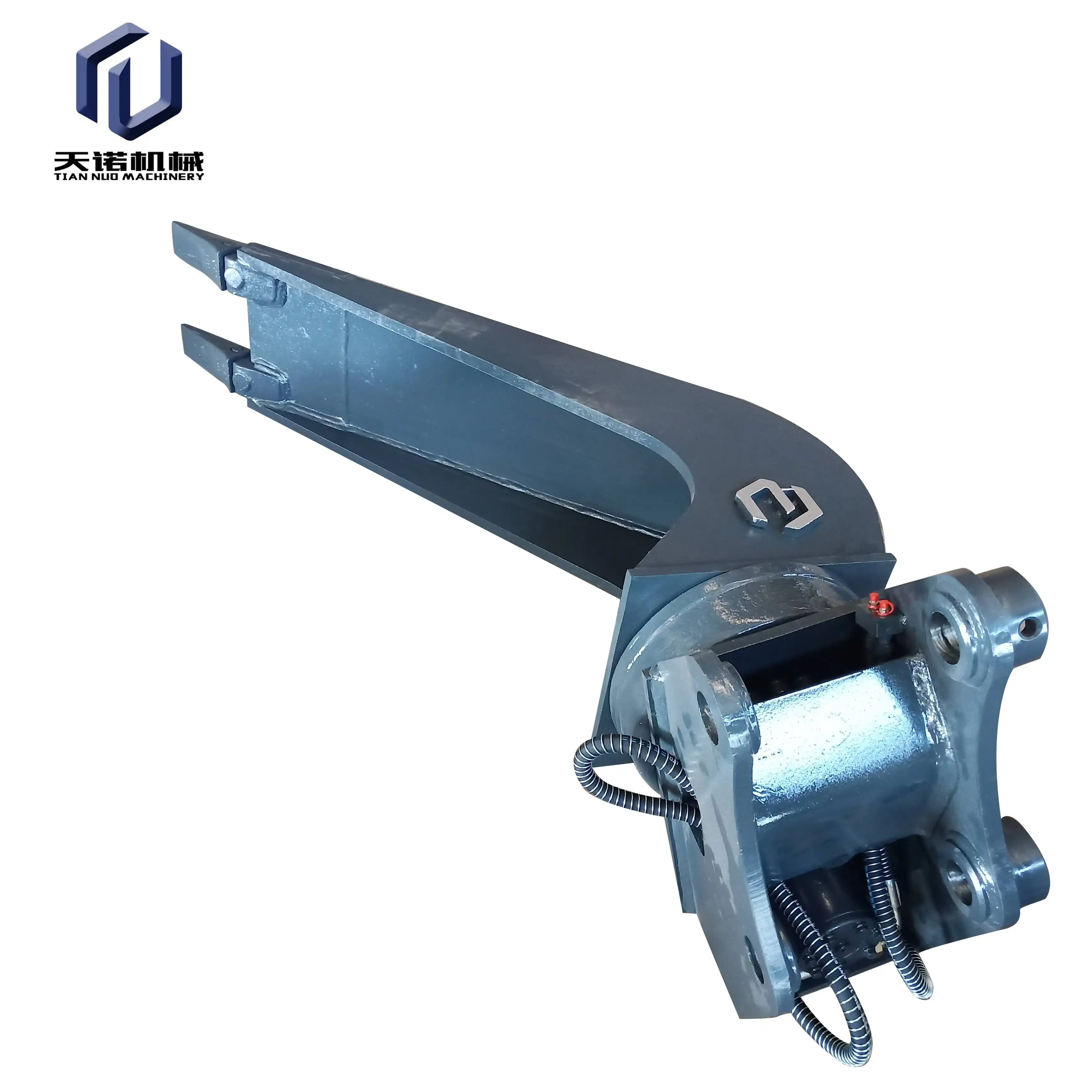

Tiannuo Machinery Excavator Grab Arm

The excavator grab arm has proven to be an invaluable asset in dock unloading operations. Its combination of versatility, efficiency, and safety features makes it an ideal choice for ports looking to optimize their material handling processes. As global trade continues to grow and ports face increasing pressure to improve their operational efficiency, the role of the excavator grab arm in maritime logistics is likely to become even more prominent.

Tiannuo offers a range of excavator grab arms designed for various applications, including dock unloading, railway transportation unloading, and waste steel handling. Our products are crafted with precision, featuring beveling welding to prevent deformation and ensure long-lasting performance. If you're in the market for a reliable excavator grab arm manufacturer, we invite you to reach out to our team. Contact our manager at arm@stnd-machinery.com, or connect with our team members at rich@stnd-machinery.com and tn@stnd-machinery.com. Let Tiannuo Machinery be your partner in enhancing your material handling capabilities and operational efficiency.

References:

- Port Technology International. (2021). "The Evolution of Port Handling Equipment."

- Journal of Shipping and Trade. (2020). "Safety and Efficiency in Modern Port Operations."

- Maritime Engineering Journal. (2022). "Advancements in Bulk Material Handling Technologies for Ports."