Why is the excavator rail clamp material Q460+WH60C?

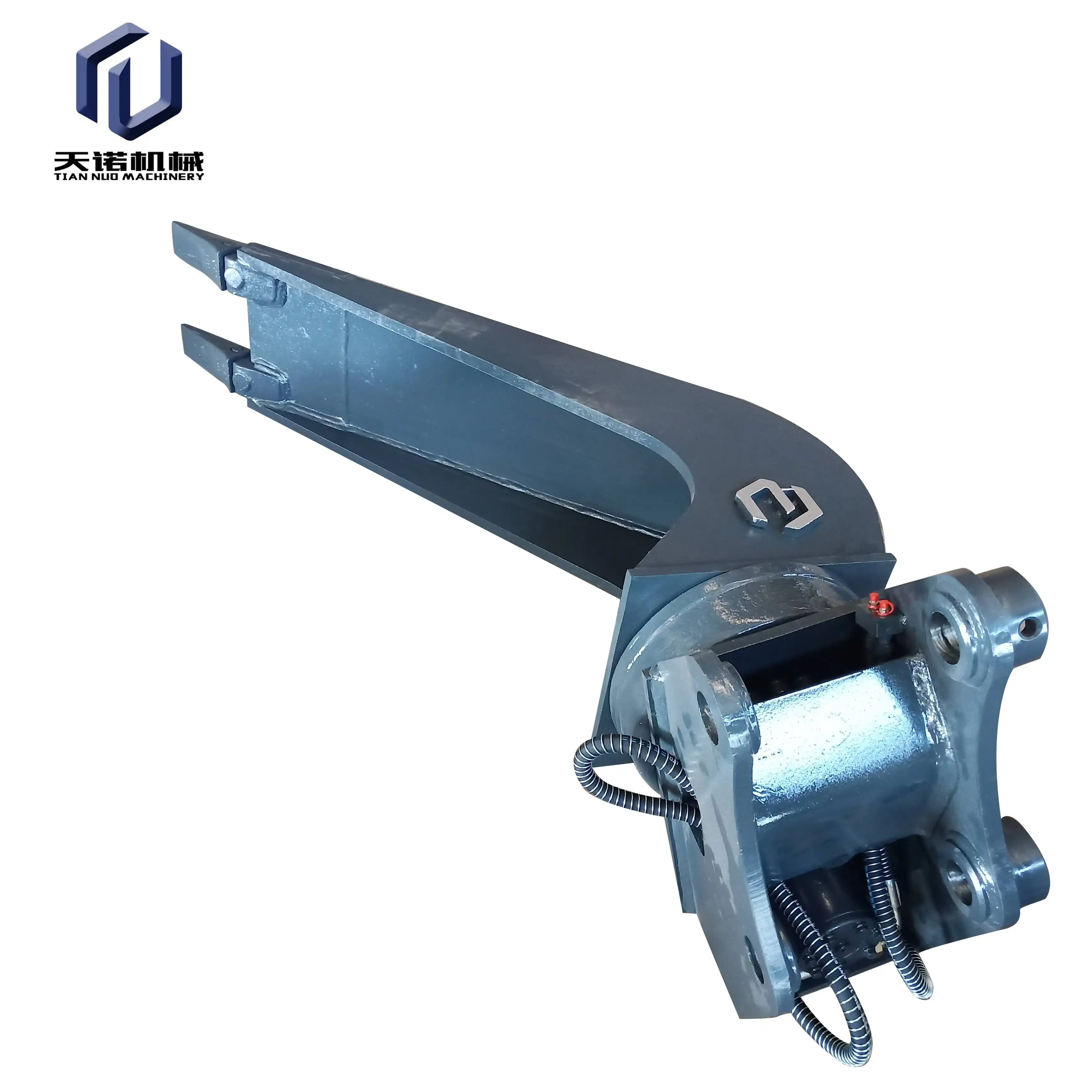

The selection of equipment and materials is a crucial factor in ensuring efficiency, safety, and longevity in railway construction and maintenance. The excavator rail clamp, a specialized attachment designed to securely grasp and manipulate railway tracks, is one essential tool in this industry. However, have you ever considered the reason why these clamps are made of the material Q460+WH60C? We will investigate the significance of this one-of-a-kind material composition and delve deeply into the world of excavator rail clamps in this article.

Material Q460+WH60C

The sequence Q460+WH60C represents more than just a combination of letters and numbers; it denotes a meticulously engineered material designed for optimal performance in excavator rail clamps. WH60C is a wear-resistant steel, while Q460 is a high-strength, low-alloy structural steel. When combined, these materials form a robust and durable composite ideal for the demanding requirements of railway maintenance tasks. This combination ensures exceptional strength and resistance to wear, making it well-suited for the rigors of rail support operations, thereby enhancing both the reliability and longevity of the equipment used in these critical applications.

The clamp's ability to endure the high stresses associated with gripping and moving heavy rail sections is largely due to the exceptional strength and toughness of the Q460 component. With a yield strength of at least 460 MPa, this grade of steel is ideal for load-bearing applications. Meanwhile, the WH60C element offers outstanding wear resistance, crucial for prolonging the clamp's lifespan in abrasive environments. Together, these materials ensure that the clamp performs reliably under demanding conditions, making it a vital component for maintaining the integrity and safety of rail infrastructure.

Working Environment And Requirements Of Excavator Rail Clamp

Excavator rail clamps operate in some of the most challenging conditions within the construction and maintenance industry. They are required to deliver consistent performance across a wide range of environments, from freezing temperatures to scorching heat. This exposure to varying weather conditions demands that the clamps remain reliable and efficient at all times. Furthermore, during operation, these clamps endure significant mechanical stresses, continuous vibrations, and the potential for impacts, all of which can affect their integrity and functionality. To meet these rigorous demands, the clamps must be engineered for durability and resilience, ensuring they can withstand the harsh realities of railway construction and maintenance tasks while maintaining safety and performance standards.

The following are the essential requirements for an excavator rail clamp:

High solidarity to safely grasp and lift weighty rail areas

Astounding wear protection from endure rough contact with rails and stabilizer

Erosion protection from persevere through openness to different atmospheric conditions

Sturdiness to ingest shocks and effects without disappointment

Layered solidness to keep up with exact grasping power

Considering these demanding requirements, it's clear why a specialized material like Q460+WH60C is essential. The high strength of Q460 combined with the wear resistance of WH60C ensures that the excavator rail clamp can perform effectively and reliably over an extended period. This durable material combination not only meets the rigorous challenges of heavy rail operations but also enhances the clamp's longevity, reducing the need for frequent replacements. As a result, the clamp remains a dependable component in maintaining the safety and efficiency of railway infrastructure, making it invaluable in the industry.

Application Of Q460+WH60C In Excavator Rail Clamp

The material's versatility and effectiveness are evident in its application for excavator rail clamps. The high-strength Q460 component delivers the essential rigidity and load-bearing capacity required for optimal performance. This ensures that the clamp remains stable and does not deform or fail, even when securing rail sections weighing several tons. By combining strength with reliability, the Q460 component plays a crucial role in maintaining the integrity of the clamp, making it well-suited for the demanding conditions of railway construction and maintenance. This adaptability enhances the overall efficiency and safety of rail operations.

The gripping surfaces and pivot points of the clamp, which are prone to wear, are the strategically applied WH60C element. By minimizing material loss due to abrasion, this wear-resistant steel significantly extends the operational life of the clamp. Consequently, maintenance intervals can be extended, reducing operational costs and downtime for railway contractors and maintenance companies.

Additionally, the clamp design can be optimized for optimal weight distribution thanks to the composite nature of Q460+WH60C. Because it helps maintain the excavator's stability and lifting capacity, this is especially crucial for attachments. The material's excellent strength-to-weight ratio makes it possible to make clamps that are strong but light, improving the efficiency of railway maintenance.

It is important to note that Shandong Tiannuo's R&D team was the first to incorporate this cutting-edge material into their excavator rail clamps. Their clamps are favored by railway contractors all over the world due to their versatility in handling a variety of rail sizes and maximum opening of 415 mm. In their products, they use Q460+WH60C, which demonstrates their dedication to quality and innovation in railway maintenance equipment.

Shandong Tiannuo Excavator Rail Clamps

The selection of Q460+WH60C as the excavator rail clamp is by no means arbitrary. It is a well-thought-out engineering decision that addresses the particular difficulties associated with railway maintenance work. This material ensures that excavator rail clamps can function reliably in challenging conditions by combining high strength, wear resistance, and durability. This makes railway operations safer and more efficient. Building on the solid foundation that Q460+WH60C has established, we can anticipate additional material and design innovations as the railway industry continues to evolve.

Shandong Tiannuo can be reached at arm@stnd-machinery.com if you are looking for high-quality manufacturers of excavator rail clamps. They are a dependable partner for your railway maintenance requirements due to their proficiency in incorporating cutting-edge materials like Q460+WH60C into their products.

References

1. Wang, Y., & Liu, J. (2019). Wear Behavior of High-Strength Low-Alloy Steels: A Comparative Study. Materials Science and Engineering: A, 742, 430-439.

2. Zhang, L., et al. (2020). Performance Analysis of Railway Maintenance Equipment: Focus on Material Selection. Journal of Rail and Rapid Transit, 234(5), 553-565.

3. Li, X., & Chen, Y. (2021). Advancements in Excavator Attachments for Railway Applications. Construction and Building Materials, 305, 124762.

YOU MAY LIKE

VIEW MOREHigh-vibration hydraulic ballast tamping machine

VIEW MOREHigh-vibration hydraulic ballast tamping machine VIEW MOREExcavator ballast cleaning hopper

VIEW MOREExcavator ballast cleaning hopper VIEW MOREClamshell Buckets for Excavators for sale

VIEW MOREClamshell Buckets for Excavators for sale VIEW MOREExcavators Long Reach Boom

VIEW MOREExcavators Long Reach Boom VIEW MORELoader Arm Extensions

VIEW MORELoader Arm Extensions VIEW MOREExcavator Ripper

VIEW MOREExcavator Ripper VIEW MOREStandard Size Excavator Boom And Arm

VIEW MOREStandard Size Excavator Boom And Arm VIEW MORERailway Excavator Ballast Plow

VIEW MORERailway Excavator Ballast Plow