Why is construction speed critical for an excavator vibratory compactor?

In the world of construction and earthwork, efficiency is key. One of the most crucial elements in achieving this efficiency is the proper use of an excavator vibratory compactor. These powerful machines play a vital role in soil compaction, a process essential for creating stable foundations for various structures. But why is construction speed so critical when using these devices? Let's delve into this topic and explore the factors that influence the construction speed of a vibratory compactor, how soil bearing capacity affects the ideal speed, and the risks associated with improper speed management.

What Factors Influence the Construction Speed of a Vibratory Compactor?

The construction speed of an excavator vibratory compactor is influenced by several factors, each playing a crucial role in determining the overall efficiency and effectiveness of the compaction process. Understanding these factors is essential for optimizing the use of the compactor and achieving the desired results in the most time-efficient manner.

1. Soil Type: The nature of the soil being compacted significantly impacts the speed at which an excavator vibratory compactor can operate effectively. Different soil types, such as clay, sand, or gravel, respond differently to compaction forces. For instance, cohesive soils like clay may require slower speeds and more passes to achieve proper compaction, while granular soils like sand might compact more quickly.

2. Moisture Content: The amount of moisture in the soil is another critical factor. Optimal moisture content can facilitate faster and more effective compaction, as it helps in reducing friction between soil particles. However, excessive moisture can lead to soil instability, necessitating slower compaction speeds.

3. Layer Thickness: The thickness of the soil layer being compacted affects the speed at which the vibratory compactor can operate. Thinner layers generally allow for faster compaction speeds, while thicker layers may require slower speeds and multiple passes to achieve uniform compaction throughout the depth.

4. Compactor Specifications: The technical specifications of the excavator vibratory compactor itself play a significant role. Factors such as the weight of the compactor, the frequency and amplitude of vibration, and the size of the compaction drum all influence the speed at which effective compaction can be achieved.

5. Project Requirements: The specific compaction requirements of a project, such as the desired density or bearing capacity, can dictate the speed at which the compactor must operate. More stringent requirements may necessitate slower speeds and more passes to ensure thorough compaction.

6. Operator Skill: The expertise and experience of the operator can significantly impact the construction speed. A skilled operator can optimize the compactor's speed based on real-time assessment of soil conditions and compaction progress.

7. Environmental Conditions: Factors such as temperature and humidity can affect soil behavior and, consequently, the optimal compaction speed. Extreme weather conditions may require adjustments to the compaction process.

Understanding and managing these factors is crucial for achieving the right balance between speed and compaction quality. It's important to note that while increasing speed may seem beneficial for project timelines, it should never come at the cost of compaction quality.

How Does Soil Bearing Capacity Affect the Ideal Construction Speed?

Soil bearing capacity, which refers to the ability of soil to support the loads applied to it without undergoing shear failure, plays a significant role in determining the ideal construction speed for an excavator vibratory compactor. This relationship is complex and multifaceted, with several important considerations:

1. Initial Bearing Capacity: Soils with lower initial bearing capacity generally require slower compaction speeds. This allows more time for the compaction forces to overcome the soil's resistance and achieve the desired density. Conversely, soils with higher initial bearing capacity may allow for faster compaction speeds.

2. Compaction Energy Transfer: The efficiency of energy transfer from the vibratory compactor to the soil is influenced by the soil's bearing capacity. Soils with higher bearing capacity tend to transmit compaction energy more effectively, potentially allowing for faster compaction speeds without compromising quality.

3. Soil Deformation: Soils with lower bearing capacity are more prone to deformation under the weight and vibration of the compactor. This can necessitate slower speeds to prevent over-compaction or soil instability, especially in the initial passes.

4. Compaction Passes: The number of passes required to achieve the desired compaction is often inversely related to the soil's bearing capacity. Soils with higher bearing capacity may require fewer passes, allowing for potentially higher overall construction speeds.

5. Moisture Sensitivity: Soils with lower bearing capacity are often more sensitive to moisture content. This can require more careful control of compaction speed to avoid creating excess pore water pressure, which can lead to soil instability.

6. Depth of Influence: The depth to which the compaction forces effectively penetrate is influenced by the soil's bearing capacity. Soils with higher bearing capacity may allow for deeper penetration of compaction forces, potentially allowing for thicker lifts and faster overall progress.

7. Dynamic Response: The dynamic response of the soil to vibratory compaction is closely tied to its bearing capacity. Soils with higher bearing capacity may respond more favorably to higher frequency vibrations, potentially allowing for faster compaction speeds.

It's crucial to note that while soil bearing capacity significantly influences the ideal construction speed, it should not be considered in isolation. Factors such as moisture content, layer thickness, and specific project requirements must also be taken into account when determining the optimal compaction speed.

What are the Risks of Uneven Compaction Due to Improper Speed?

Uneven compaction resulting from improper speed management of an excavator vibratory compactor can lead to several significant risks and challenges in construction projects. These issues can compromise the integrity of the structure being built and lead to costly repairs or reconstructions. Here are some of the key risks associated with uneven compaction:

1. Differential Settlement: One of the most serious consequences of uneven compaction is differential settlement. This occurs when different areas of the compacted soil settle at different rates or to different degrees. Differential settlement can lead to structural issues in buildings, cracks in pavements, and instability in earthworks.

2. Reduced Load-Bearing Capacity: Uneven compaction can result in areas of soil with lower density and, consequently, reduced load-bearing capacity. This can lead to localized failures under applied loads, potentially causing structural damage or failure.

3. Water Infiltration and Erosion: Areas of under-compacted soil can become pathways for water infiltration. This can lead to increased erosion, soil washing, and potential undermining of structures. In severe cases, it can contribute to slope instability or foundation problems.

4. Pavement Distress: In road construction, uneven compaction can lead to various forms of pavement distress. This includes rutting, cracking, and pothole formation, all of which can significantly reduce the lifespan of the road and increase maintenance costs.

5. Inconsistent Soil Properties: Uneven compaction results in soil with varying properties across the site. This inconsistency can make it challenging to predict soil behavior under loads, complicating design and potentially leading to over-conservative (and thus more expensive) designs.

6. Increased Permeability: Under-compacted areas can have higher permeability, leading to increased water flow through the soil. This can be particularly problematic in dam construction or other projects where controlling water flow is critical.

7. Reduced Earthquake Resistance: In seismic zones, uneven compaction can lead to differential amplification of seismic waves, potentially increasing the risk of damage during earthquakes.

8. Construction Delays and Increased Costs: If uneven compaction is detected during quality control tests, it often necessitates reworking of the affected areas. This can lead to significant project delays and increased construction costs.

9. Long-Term Maintenance Issues: Even if not immediately apparent, uneven compaction can lead to long-term maintenance issues. These may manifest as recurring pavement repairs, foundation issues, or ongoing settlement problems.

10. Environmental Impact: In some cases, uneven compaction can lead to increased erosion and sediment runoff, potentially impacting local ecosystems and water quality.

To mitigate these risks, it's crucial to maintain proper speed control when operating an excavator vibratory compactor. This involves not only adhering to recommended speed ranges but also adjusting speed based on real-time assessment of soil conditions and compaction progress. Regular quality control testing, such as in-situ density tests, can help detect and address compaction issues before they lead to more serious problems.

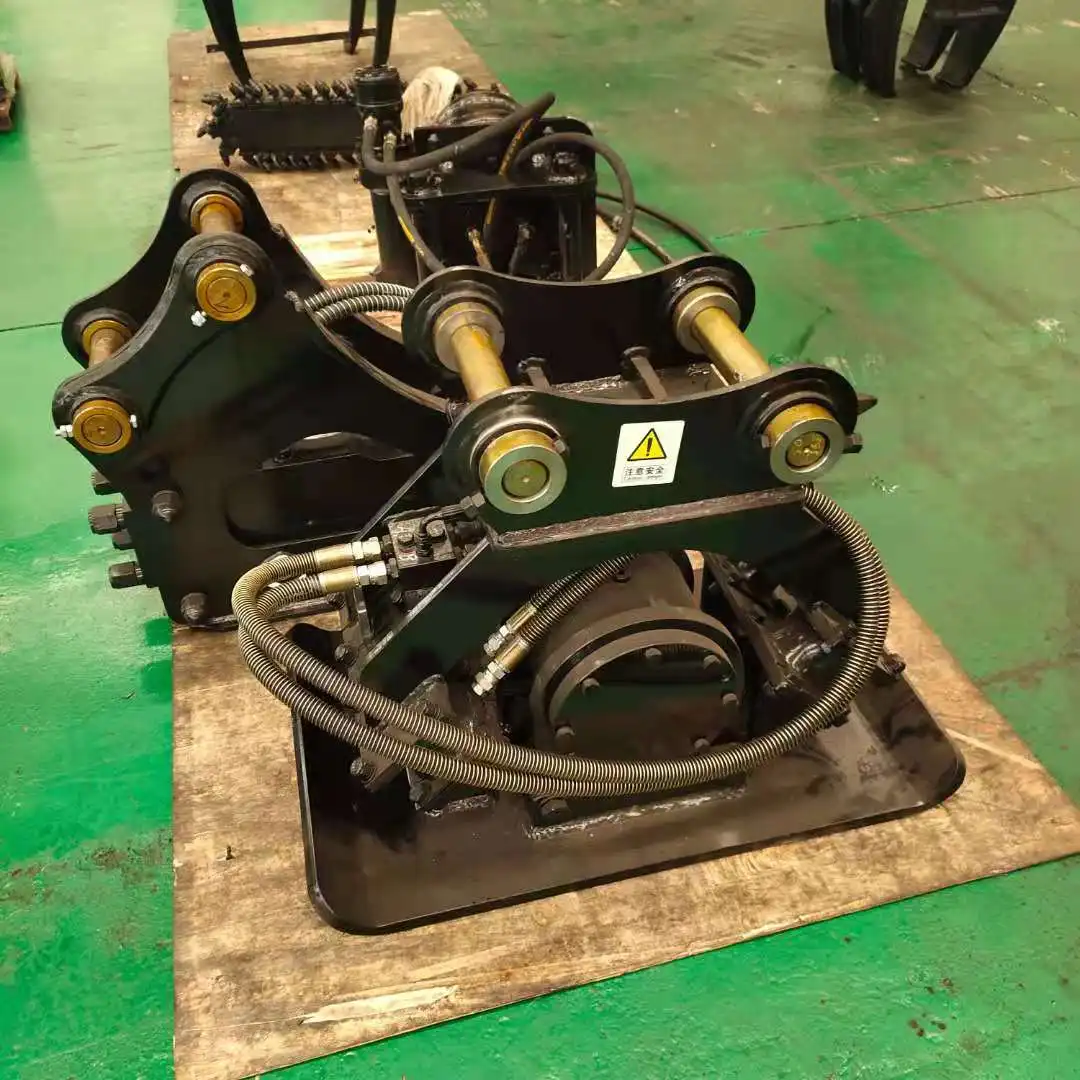

Excavator Vibratory Compactor Supplier

The construction speed of an excavator vibratory compactor is a critical factor that significantly impacts the efficiency and quality of soil compaction projects. By understanding the various factors that influence this speed, including soil type, moisture content, and soil bearing capacity, contractors can optimize their compaction processes for better results. Moreover, recognizing the risks associated with improper speed management underscores the importance of careful operation and regular quality control.

At Tiannuo Machinery, we bring over 10 years of expertise in manufacturing high-quality excavator vibratory compactors. As a leading name in the construction equipment industry, we are committed to innovation, reliability, and customer satisfaction. If you are choosing your excavator vibratory compactor manufacturer, welcome to contact Our manager's email is arm@stnd-machinery.com and the team's emails are rich@stnd-machinery.com and tn@stnd-machinery.com.

References:

[1] Holtz, R. D., Kovacs, W. D., & Sheahan, T. C. (2011). An introduction to geotechnical engineering. Pearson.

[2] Das, B. M. (2015). Principles of foundation engineering. Cengage learning.

[3] Proctor, R. R. (1933). Fundamental principles of soil compaction. Engineering news-record, 111(9), 245-248.

[4] Forssblad, L. (1981). Vibratory soil and rock fill compaction. Dynapac Maskin AB.

[5] ASTM D1557-12e1. (2012). Standard Test Methods for Laboratory Compaction Characteristics of Soil Using Modified Effort. ASTM International.

[6] Parsons, A. W. (1992). Compaction of soils and granular materials: a review of research performed at the Transport Research Laboratory. HMSO.