What to do with excavator metal scrap?

As the construction and demolition industries continue to evolve, the question of what to do with excavator metal scrap has become increasingly important. Excavators are essential machines in various projects, from building sites to mining operations. However, when these powerful machines reach the end of their lifecycle, they leave behind a significant amount of metal scrap. This article explores the various options available for dealing with excavator metal scrap, focusing on sustainable and economically viable solutions.

Scrap Yards: A Traditional Approach to Excavator Metal Scrap

Scrap yards have long been a go-to solution for disposing of excavator metal scrap. These facilities specialize in processing and recycling various types of metal waste, including the heavy-duty components found in excavators. When an excavator is no longer operational or has been decommissioned, sending it to a scrap yard can be an effective way to recycle its metal components.

At a scrap yard, the excavator is typically dismantled, and its parts are sorted based on the type of metal. Steel, which makes up a significant portion of an excavator's structure, is separated from other metals like copper (found in wiring) and aluminum (used in some components). This sorting process is crucial as different metals have varying recycling processes and market values.

One of the primary advantages of using scrap yards for excavator metal scrap is the potential for financial return. Many scrap yards offer payment for metal waste, with the amount depending on the current market rates for different metals. This can provide a modest return on investment for companies or individuals looking to dispose of old excavators.

However, it's important to note that not all scrap yards are equipped to handle large machinery like excavators. When choosing a scrap yard, it's crucial to select one with the necessary equipment and expertise to safely and efficiently process heavy construction equipment. This ensures that the maximum amount of metal is recycled and that the process is carried out in an environmentally responsible manner.

Metal Recycling Facilities: Specialized Solutions for Excavator Metal Scrap

While scrap yards offer a general solution for metal waste, metal recycling facilities provide a more specialized approach to handling excavator metal scrap. These facilities are often better equipped to deal with the unique challenges presented by large construction equipment.

Metal recycling facilities typically employ advanced technologies to process excavator metal scrap more efficiently. This can include automated sorting systems that use magnets and eddy currents to separate different types of metals, as well as shredders capable of breaking down large metal pieces into smaller, more manageable sizes.

One of the key advantages of using metal recycling facilities is their ability to recover a higher percentage of usable metal from excavator scrap. This is particularly important for rare or valuable metals that might be present in small quantities within the excavator's components. For instance, the catalytic converters in excavators often contain precious metals like platinum, palladium, and rhodium, which can be extracted and recycled.

Furthermore, metal recycling facilities often have established relationships with manufacturers who use recycled metals in their production processes. This creates a more direct path for the recycled excavator metal scrap to re-enter the manufacturing cycle, promoting a circular economy approach.

It's worth noting that the recycling process at these facilities goes beyond just the metal components. Many modern recycling facilities also handle other materials found in excavators, such as rubber from tires and hoses, or plastic from various parts. This comprehensive approach ensures that as much of the excavator as possible is recycled or repurposed, minimizing waste sent to landfills.

Demolition Projects: Repurposing Excavator Metal Scrap On-Site

Demolition projects present a unique opportunity for repurposing excavator metal scrap directly on-site. In many cases, the metal components of decommissioned excavators can be immediately put to use in ongoing demolition work, creating an efficient closed-loop system.

One common practice is to use the metal from old excavators to reinforce temporary structures used in demolition projects. For example, the sturdy steel from an excavator's boom or arm can be repurposed to create support beams or braces. This not only reduces the need for new materials but also cuts down on transportation costs and associated environmental impacts.

Another innovative approach is to use excavator metal scrap in the creation of erosion control structures on demolition sites. Large metal pieces can be strategically placed to prevent soil erosion, especially in areas where heavy machinery has disturbed the natural landscape. This repurposing not only addresses a practical need but also demonstrates a commitment to sustainable construction practices.

Some demolition companies have even found ways to incorporate excavator metal scrap into artistic installations or functional structures that remain after the demolition is complete. This could include using the metal to create decorative fencing, outdoor sculptures, or even structural elements in new buildings, showcasing the potential for creative reuse of these materials.

It's important to note that while repurposing excavator metal scrap on-site can be highly efficient, it requires careful planning and adherence to safety regulations. Any repurposing should be done under the guidance of qualified engineers to ensure the structural integrity and safety of the repurposed materials.

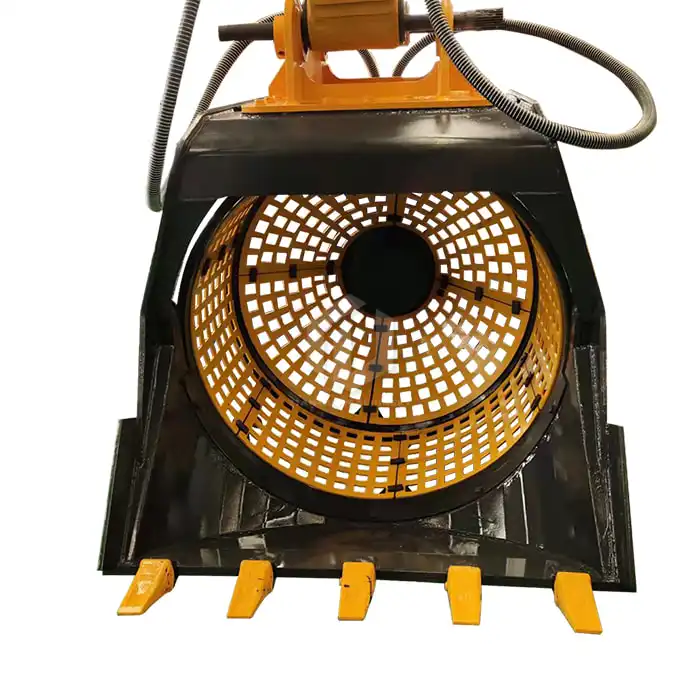

Excavator Metal Scrap Supplier

The excavator metal scrap from Tiannuo Machinery offers versatile hydraulics for precise control in any operation, ensuring smooth and accurate handling of metal scraps. It features a durable design, constructed with high-strength manganese steel, which provides long-lasting reliability and resistance to wear and tear. The user-friendly controls make it easy to operate for extended periods, reducing operator fatigue. Available in customizable sizes, it fits excavators ranging from 6 to 24 tons, making it a versatile choice for various applications. If you are choosing your excavator metal scrap manufacturer, please feel free to reach out to our manager at arm@stnd-machinery.com and the team at rich@stnd-machinery.com and tn@stnd-machinery.com.

References:

- Environmental Protection Agency. (2021). Scrap Metal Recycling: A Guide for Industry.

- Journal of Cleaner Production. (2020). Advanced Metal Recycling Technologies: Principles and Applications.

- Construction and Demolition Recycling Association. (2022). Best Practices for On-Site Material Reuse in Demolition Projects.