What size is a typical front-end loader bucket?

A typical front loader bucket ranges significantly in size, generally between 1 to 6 cubic yards (0.76 to 4.6 cubic meters) for standard wheel loaders. The exact size depends largely on the machine's operating capacity and intended application. Compact wheel loaders typically feature buckets ranging from 1 to 1.5 cubic yards, while mid-sized loaders commonly use 2 to 3.5 cubic yard buckets. Large production loaders found in mining operations may utilize buckets exceeding 10 cubic yards. Beyond capacity, bucket dimensions vary in width (typically 7 to 12 feet or 2.1 to 3.7 meters), depth (3 to 6 feet or 0.9 to 1.8 meters), and weight (sometimes exceeding several tons for larger models). The appropriate bucket size must be carefully selected based on material density, project requirements, machine compatibility, and operational efficiency considerations to maximize productivity while avoiding machine strain or instability.

Bucket Capacity

Volume Measurements

The capacity of a front loader bucket is typically measured in cubic yards or cubic meters, indicating the volume of material it can carry. This measurement represents the struck capacity - the amount the bucket can hold when filled level to its brim without any heaping. Heaped capacity, which includes the natural pile of material that forms above the bucket rim, is often 10-15% higher than struck capacity.

For contractors and site managers, understanding these capacity distinctions is crucial when estimating material movement requirements and planning project timelines. A bucket's rated capacity directly affects loading cycle efficiency and the number of passes required to complete material handling tasks.

Size Ranges by Loader Class

Front loader buckets are manufactured in various sizes corresponding to different loader classes:

Mini loaders (under 50 HP): 0.5-1 cubic yard buckets

Compact loaders (50-80 HP): 1-1.5 cubic yards

Mid-size loaders (80-150 HP): 2-3.5 cubic yards

Full-size loaders (150-250 HP): 3.5-5 cubic yards

Production loaders (250+ HP): 5-10+ cubic yards

These size categories ensure proper matching between the bucket and the machine's lifting capacity, hydraulic power, and frame strength. Using an oversized bucket on an underpowered loader creates operational hazards and accelerates mechanical wear.

Application-Specific Variations

Bucket capacities vary substantially based on intended applications:

General purpose buckets typically feature moderate capacities optimized for versatility across different materials. Light material buckets, designed for low-density materials like mulch or snow, offer larger volumes without exceeding the loader's weight limitations. Rock buckets feature reinforced construction with smaller capacities to handle dense, abrasive materials without overloading the machine.

In specialized environments like waste management, high-capacity buckets with integrated spillguards accommodate bulky, lightweight materials. Conversely, mining operations often employ heavy-duty buckets with reduced capacity but enhanced structural integrity for handling dense ores and aggregates.

Width (b) And Bottom Width (bw)

Standard Width Dimensions

The width dimension of a front loader bucket is a critical measurement that directly impacts operational efficiency and maneuverability. Standard bucket widths typically range from 84 inches (2.1 meters) on compact loaders to 144 inches (3.7 meters) on large production models.

Width specifications must accommodate the machine's operational parameters - the bucket should neither be narrower than the loader's wheel track (which would leave uncleared areas during operation) nor significantly wider than the machine itself (which could create maneuverability issues in confined spaces). Most manufacturers design buckets approximately 4-8 inches wider than the loader's tire width on each side to ensure complete material collection while maintaining reasonable handling characteristics.

For specialized applications like trenching or precision material placement, narrower buckets may be preferred despite their reduced capacity. Conversely, snow removal and light material handling often benefit from extra-wide bucket configurations.

Bottom Width Considerations

The bottom width (bw) of loader buckets represents the measurement across the bucket floor and differs from the overall width measurement taken at the cutting edge or bucket sides. This dimension typically ranges from 10-15% narrower than the maximum bucket width, creating the characteristic tapered shape that facilitates material flow and discharge.

This tapering design serves multiple purposes: it reduces material adhesion during dumping, improves penetration when collecting dense materials, and provides structural reinforcement against twisting forces. In specialized applications involving sticky materials like clay or wet soil, buckets with more pronounced tapering (greater difference between width and bottom width) prevent material buildup and improve discharge efficiency.

Width-to-Capacity Relationship

The correlation between bucket width and capacity follows predictable patterns across loader classes. Generally, for every 12-inch increase in bucket width, capacity increases by approximately 0.5-0.75 cubic yards, assuming consistent depth dimensions.

This relationship allows equipment managers to optimize bucket selection based on specific requirements:

Material density considerations (heavier materials require narrower buckets with less capacity)

Operational environment constraints (tight workspaces necessitate narrower configurations)

Production targets (wider buckets potentially increasing per-cycle material movement)

Custom width configurations are available for specialized applications, though these typically come at premium pricing and may affect warranty considerations for both the bucket and the loader itself.

Depth (a)

Measuring Bucket Depth Properly

The depth dimension (a) of a front loader bucket refers to the horizontal distance from the cutting edge to the rear wall of the bucket. This critical measurement typically ranges from 36 to 72 inches (0.9 to 1.8 meters) depending on loader size and application requirements.

Proper depth measurement should be taken as a straight line rather than following the curvature of the bucket floor. This dimension directly influences the bucket's penetration capabilities, especially when working with compacted materials. In most standard applications, the depth-to-width ratio typically falls between 0.7:1 and 0.9:1, providing optimal material gathering characteristics without compromising structural integrity.

Equipment specifications often include both external depth (measured from the outside) and internal depth (the actual usable space), with differences accounting for material thickness and structural supports. When evaluating replacement buckets, this distinction becomes particularly important.

Impact on Performance and Material Flow

Bucket depth significantly affects operational efficiency in several ways. Deeper buckets provide greater material retention during lifting and carrying phases, reducing spillage when transporting loose materials. However, excessive depth can hinder visibility for operators and create uneven wear patterns on the cutting edge.

For materials with higher angles of repose (like dry sand or gravel), moderately deep buckets maximize filling efficiency. Conversely, materials with lower angles of repose (like wet soil or clay) benefit from shallower designs that facilitate complete discharge and prevent material adhesion to bucket surfaces.

The relationship between depth and power requirements is particularly noteworthy - each 6-inch increase in bucket depth typically requires approximately 8-12% more breakout force from the loader's hydraulic systems to achieve full penetration in compacted materials.

Depth Variations for Specialized Tasks

Different operational requirements often necessitate specialized depth configurations:

Excavation-focused buckets feature greater depths (with depth-to-width ratios approaching 1:1) to maximize material removal per pass

Material handling buckets utilize moderate depths optimized for loading and transportation efficiency

Grading buckets implement shallower designs with extended cutting edges for precision surface work

In cold-weather applications, buckets with reduced depth but increased width provide better performance when handling snow or ice. Conversely, waste handling operations often employ deeper bucket configurations with integrated top grates to maximize volume while preventing oversized materials from entering the bucket.

FAQ

1. What factors determine the ideal bucket size for my loader?

The ideal front loader bucket size depends on several factors including your machine's lift capacity, the density of materials being handled, and your specific operational requirements. Generally, your bucket shouldn't exceed 85-90% of your loader's rated operating capacity when fully loaded with the heaviest material you'll handle.

2 . How does bucket size affect fuel efficiency?

Bucket size directly impacts fuel consumption through several mechanisms. Oversized buckets require more hydraulic power and engine output to fill and lift, potentially increasing fuel consumption by 15-25% compared to properly sized alternatives. The additional weight of larger buckets also increases the machine's base fuel requirements even during unloaded travel.

3 .Can I use the same bucket size for different materials?

Using the same bucket size for varying materials presents efficiency challenges due to density differences. While technically possible, this approach often compromises operational efficiency. Materials like coal (approximately 1,000 lb/yd³) allow full bucket utilization without exceeding machine capacity, while dense materials like crushed stone (approximately 2,700 lb/yd³) might require bucket loads to be limited to 50-60% capacity to prevent overloading.

4. What's the difference between GP and HD bucket dimensions?

General Purpose (GP) and Heavy-Duty (HD) buckets differ significantly in dimensional specifications despite similar capacity ratings. HD buckets typically feature thicker steel throughout (often 1.5-2 times thicker than GP equivalents), additional internal reinforcements, and more robust cutting edges. These structural differences result in HD buckets being approximately 15-20% heavier than GP alternatives of identical volume.

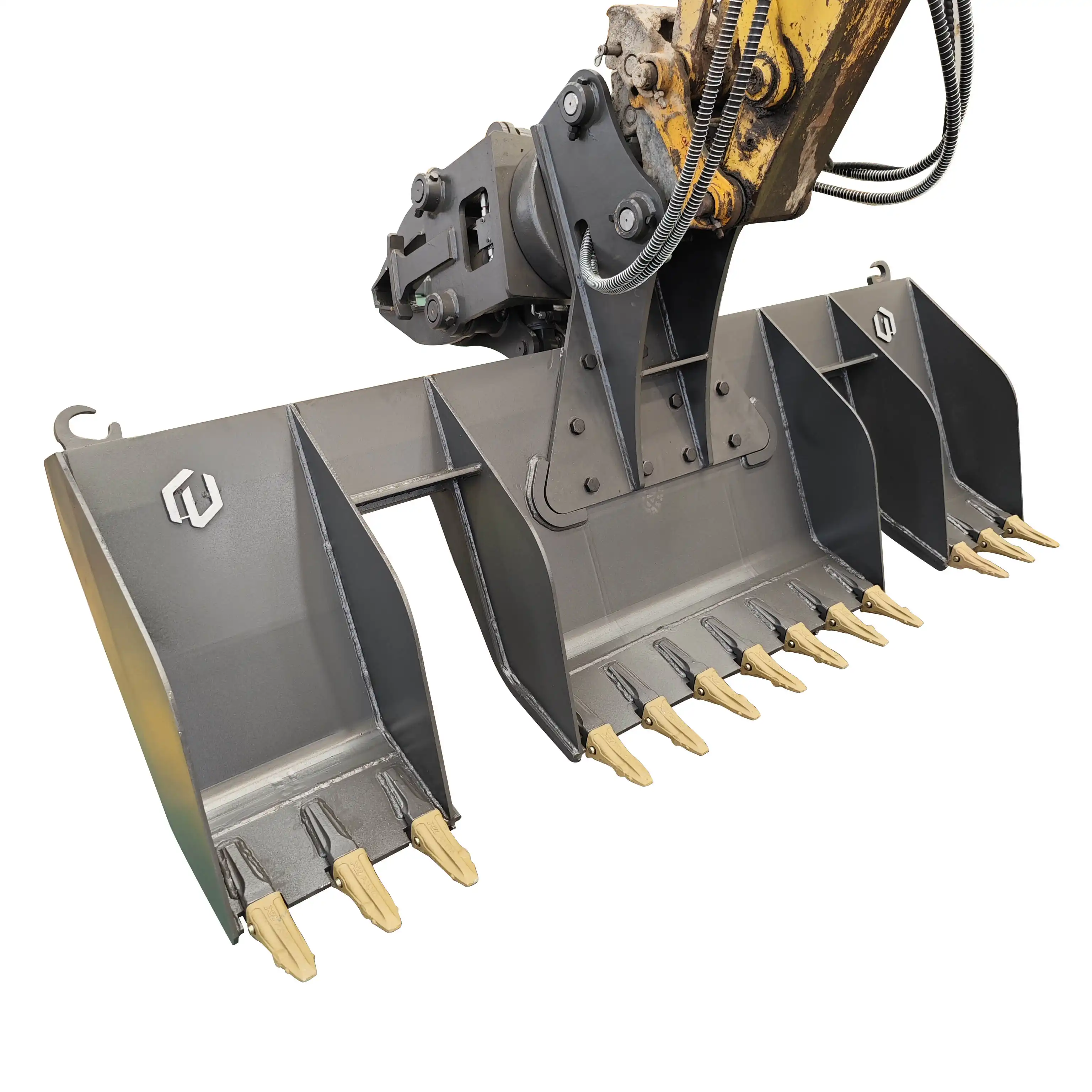

Bucket Loader For Sale

Eager to improve your loading efficiency? Tiannuo's front loader bucket is here to help. Our bucket, exemplified by the Shante ZL50 model, has a width of 2.24 m, a bottom width of 0.5969 m, and a depth of 0.025 m. It also features a rated load of 5000 kg, an unloading height of 3090 mm, and a maximum breakout force of 170 kN. Contact us at arm@stnd-machinery.com, rich@stnd-machinery.com, or tn@stnd-machinery.com to learn more about how our bucket can benefit your business.

References

Construction Equipment Guide. "Loader Bucket Sizing and Selection: Maximizing Operational Efficiency." Equipment Selection Quarterly, 2023.

Journal of Construction Engineering. "Dimensional Analysis of Earth-Moving Equipment: Optimizing Bucket Parameters." Volume 42, Issue 3, 2022.

International Mining Engineering Review. "Standard Dimensions and Capacity Ratings for Front-End Loader Attachments." Technical Supplement, 2023.

Heavy Equipment Technical Institute. "Comprehensive Guide to Loader Bucket Specifications and Performance Metrics." 3rd Edition, 2023.

Material Handling Engineering Association. "Dimensional Standards for Earth-Moving Equipment Attachments." Industry Guidelines Publication, 2022.

Construction Equipment Maintenance Journal. "Influence of Bucket Geometry on Loader Performance and Efficiency." Research Compendium, 2023.

About Author: Arm

Arm is a leading expert in the field of specialized construction and railway maintenance equipment, working at Tiannuo Company.

YOU MAY LIKE

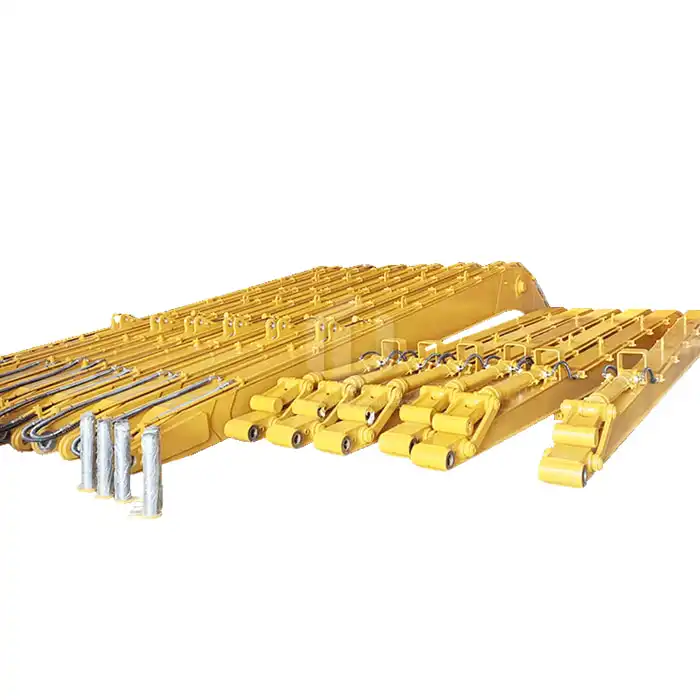

VIEW MORELong arm excavator for sale

VIEW MORELong arm excavator for sale VIEW MORERailway excavator dustpan bucket

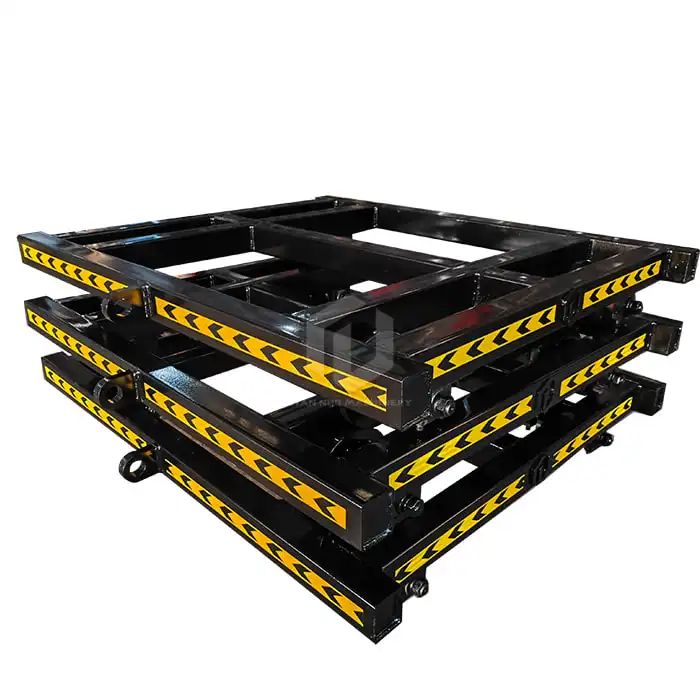

VIEW MORERailway excavator dustpan bucket VIEW MOREStaddle excavator

VIEW MOREStaddle excavator VIEW MOREExcavator High Reach Demolition Long Boom And Arm

VIEW MOREExcavator High Reach Demolition Long Boom And Arm VIEW MOREExcavator High Altitude Demolition Arm

VIEW MOREExcavator High Altitude Demolition Arm VIEW MOREExcavator Extension Arm

VIEW MOREExcavator Extension Arm VIEW MORERail Track Trolley

VIEW MORERail Track Trolley VIEW MORERailway Excavator Ballast Plow

VIEW MORERailway Excavator Ballast Plow