What is the difference between a tilt hitch and a tilt bucket?

In the world of construction and excavation, efficiency and versatility are key factors that can make or break a project. Two essential tools that have revolutionized the industry are tilt hitches and tilt buckets. While both serve to enhance the capabilities of excavators and other heavy machinery, they differ in design, function, and application. This article will delve into the intricacies of tilt hitches and degree rotating hydraulic tilt ditching buckets, exploring their unique features and helping you understand which might be the best fit for your specific needs.

What is a tilt hitch, and how does it function?

A tilt hitch is an attachment that connects to the end of an excavator's arm, allowing the operator to tilt various attachments from side to side. This innovative device significantly enhances the excavator's flexibility and range of motion, enabling it to work in tight spaces and at challenging angles that would be impossible with a standard setup.

The primary function of a tilt hitch is to provide lateral tilting capabilities to attachments such as buckets, grapples, and rippers. Most tilt hitches offer a tilt range of up to 45 degrees in either direction, effectively doubling the working range of the excavator without the need to reposition the entire machine.

Tilt hitches typically operate using hydraulic power from the excavator's system. When activated, hydraulic cylinders within the hitch move, causing the attached implement to tilt. This hydraulic operation allows for precise control and smooth movement, essential for tasks that require accuracy and finesse.

One of the key advantages of a tilt hitch is its versatility. It can be used with a wide range of attachments, making it an excellent investment for contractors who frequently switch between different tools. This adaptability can lead to significant time savings on job sites, as operators can quickly adjust their approach to various tasks without changing equipment or repositioning the excavator.

Tilt hitches are particularly useful in applications such as:

- Grading and leveling uneven surfaces

- Digging trenches on slopes

- Cleaning ditches and canals

- Landscaping and contouring

- Working around obstacles or in confined spaces

By providing this additional range of motion, tilt hitches can significantly improve productivity and reduce the need for manual labor in many construction and excavation projects.

What is a tilt bucket, and how does it differ from a standard bucket?

A degree rotating hydraulic tilt ditching bucket, also known as a tilting bucket or grading bucket, is a specialized excavator attachment designed to tilt from side to side. Unlike a standard bucket, which remains fixed in position relative to the excavator arm, a tilt bucket can rotate along its horizontal axis, typically up to 45 degrees in either direction.

The primary difference between a tilt bucket and a standard bucket lies in their design and functionality. A standard bucket is rigidly attached to the excavator arm and can only move in the directions allowed by the arm's joints. In contrast, a tilt bucket incorporates a hydraulic tilting mechanism that enables lateral movement independent of the arm's position.

This tilting capability offers several advantages:

- Increased Precision: Operators can achieve more accurate grading and contouring without repositioning the entire machine.

- Enhanced Efficiency: The ability to tilt allows for better material placement and reduces the need for multiple passes or machine repositioning.

- Improved Versatility: Tilt buckets can handle a wider range of tasks, from excavation to fine grading and slope work.

- Better Reach: The tilting function allows operators to work around obstacles and in tight spaces more effectively.

Tilt buckets are particularly useful in applications such as:

- Ditch cleaning and shaping

- Slope grading

- Landscaping and terrain contouring

- Road construction and maintenance

- Precision excavation around utilities or structures

It's worth noting that while tilt buckets offer significant advantages in terms of versatility and precision, they may have a slightly reduced capacity compared to standard buckets of the same size due to the space required for the tilting mechanism.

What are the key differences in design and operation between a tilt hitch and a tilt bucket?

While both tilt hitches and tilt buckets aim to increase the versatility and efficiency of excavation work, they differ significantly in their design, operation, and application. Understanding these differences is crucial for choosing the right tool for specific job requirements.

Design Differences:

- Attachment Point: A tilt hitch is an intermediary device that attaches to the excavator's arm, allowing various attachments to be connected to it. In contrast, a tilt bucket is a self-contained unit that attaches directly to the excavator's arm or quick coupler.

- Versatility: Tilt hitches are designed to work with multiple attachments, including standard buckets, grapples, and rippers. Tilt buckets, however, are standalone units specifically designed for excavation and grading tasks.

- Tilting Mechanism: In a tilt hitch, the tilting mechanism is part of the hitch itself, separate from any attachment. For a tilt bucket, the tilting mechanism is integrated into the bucket's design.

- Weight Distribution: Tilt hitches add extra weight between the excavator arm and the attachment, which can affect the machine's lifting capacity and balance. Tilt buckets, being integrated units, typically have a more favorable weight distribution.

Operational Differences:

- Functionality: Tilt hitches provide tilting capabilities to any compatible attachment, offering broader functionality across various tools. Tilt buckets are limited to bucket-specific tasks but excel in those applications.

- Control: Operating a tilt hitch requires coordinating the movement of both the hitch and the attached implement. Tilt buckets, being single units, may offer more intuitive control for bucket-specific tasks.

- Maintenance: Tilt hitches may require more maintenance due to their more complex design and the stress of supporting various attachments. Tilt buckets, with their integrated design, might be simpler to maintain but offer less flexibility.

- Precision: While both offer improved precision over standard buckets, tilt buckets may provide more accurate control for specific grading and contouring tasks due to their integrated design.

Application Differences:

- Versatility vs. Specialization: Tilt hitches are ideal for operations that require frequent switching between different attachments. Tilt buckets are better suited for projects that primarily involve excavation, grading, and material handling.

- Project Scale: Tilt hitches may be more cost-effective for larger operations or contractors with diverse project portfolios. Tilt buckets might be preferable for specialized earthmoving companies or smaller operations focused on specific types of work.

- Efficiency: For bucket-specific tasks, a tilt bucket might offer higher efficiency due to its purpose-built design. However, for projects requiring multiple tool changes, a tilt hitch could provide better overall efficiency.

When considering the implementation of tilting technology in excavation work, it's essential to evaluate the specific needs of your projects. Some operations might benefit from the versatility of a tilt hitch, while others may find the specialized capabilities of a tilt bucket more advantageous. In some cases, having both options available can provide the ultimate flexibility for tackling a wide range of excavation challenges.

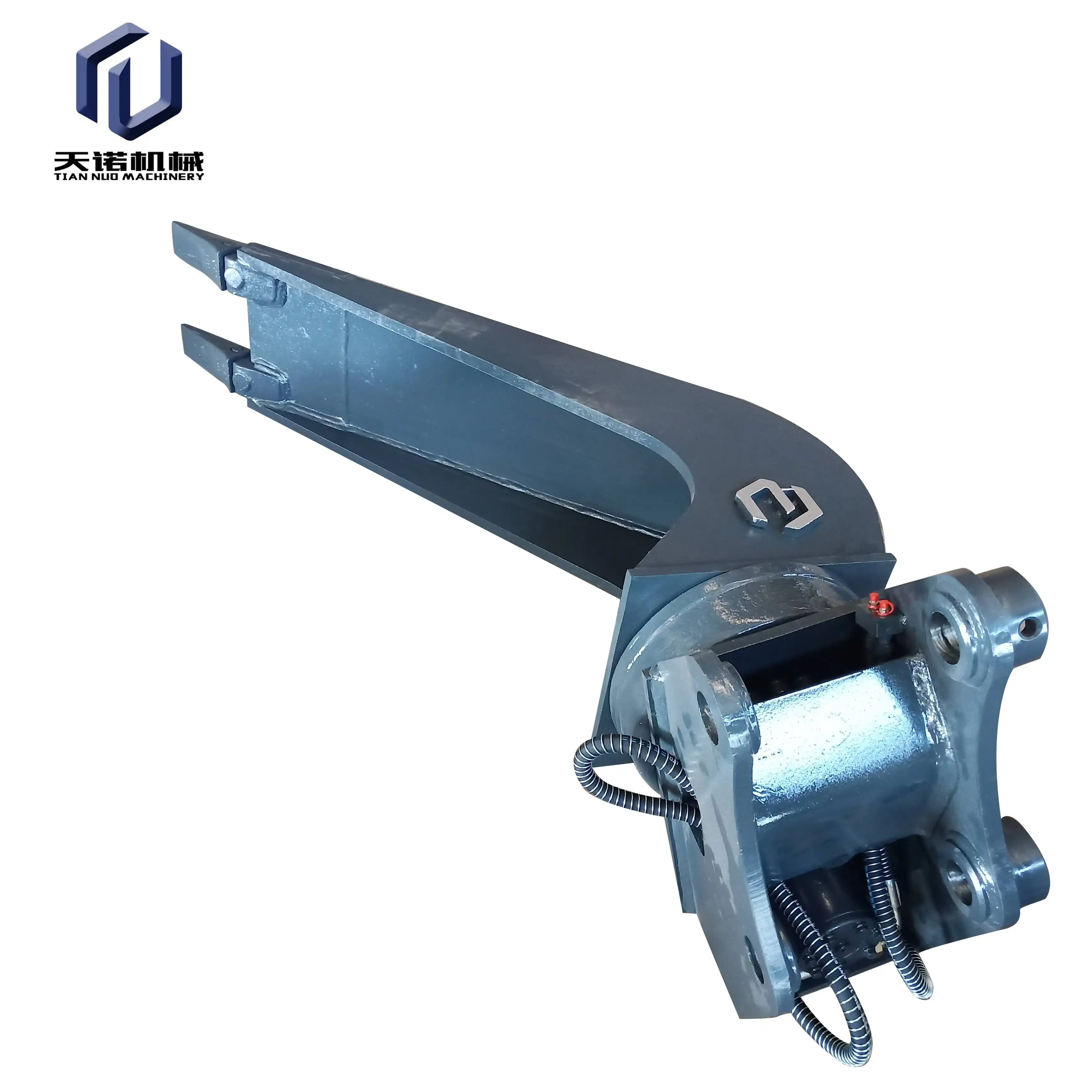

One innovative solution that combines the benefits of both tilt hitches and tilt buckets is the degree rotating hydraulic tilt ditching bucket. This advanced attachment offers enhanced versatility by providing both tilting and rotating capabilities, allowing for precise control and efficient operation in various excavation and grading tasks.

Degree Rotating Hydraulic Tilt Ditching Bucket Supplier

For those seeking a high-quality degree rotating hydraulic tilt ditching bucket, Tiannuo Machinery offers an excellent solution. Their product boasts impressive specifications, including:

- Rotation: 360 degrees

- Incline: 45 degrees

- Applicable Host Machine: 7-15 tons

- Bucket Capacity: 0.4 m³

These features make Tiannuo Machinery's degree rotating hydraulic tilt ditching bucket an ideal choice for contractors looking to maximize their excavation efficiency and versatility. The 360-degree rotation combined with a 45-degree incline offers unparalleled flexibility in positioning and operation, while the 0.4 m³ capacity ensures substantial material handling capabilities.

If you're in the market for a degree rotating hydraulic tilt ditching bucket manufacturer, we invite you to reach out to Tiannuo Machinery. Their experienced team is ready to assist you with any inquiries or requirements you may have. You can contact their manager at arm@stnd-machinery.com, or reach out to team members at rich@stnd-machinery.com and tn@stnd-machinery.com. Take the next step in optimizing your excavation operations with Tiannuo Machinery's advanced hydraulic tilt ditching bucket technology.

References:

- Construction Equipment Guide. (2021). "Tilt Rotators Increase Excavator Versatility."

- Excavator Bucket HQ. (2022). "What Is a Tilt Bucket? (And Do You Need One?)."

- Equipment World. (2020). "Tiltrotators: Why U.S. contractors' use of these excavator attachments is on the rise."

YOU MAY LIKE

VIEW MORERailway Sleeper Changer

VIEW MORERailway Sleeper Changer VIEW MOREExcavator ballast cleaning hopper

VIEW MOREExcavator ballast cleaning hopper VIEW MOREDump truck anti-skid tracks

VIEW MOREDump truck anti-skid tracks VIEW MOREClamshell Buckets for Excavators for sale

VIEW MOREClamshell Buckets for Excavators for sale VIEW MOREFolding Arm Steel Grabbing Machine

VIEW MOREFolding Arm Steel Grabbing Machine VIEW MOREClamshell Bucket

VIEW MOREClamshell Bucket VIEW MOREExcavator Rock Bucket

VIEW MOREExcavator Rock Bucket VIEW MOREStandard Size Excavator Boom And Arm

VIEW MOREStandard Size Excavator Boom And Arm