What is the bucket capacity of an excavator cab?

Excavators are essential pieces of heavy machinery in the construction and mining industries. One of the most critical components of an excavator is its excavator bucket, which determines the machine's digging capacity and overall efficiency. In this comprehensive guide, we'll explore the relationship between excavator size and bucket capacity, how bucket capacity affects excavation efficiency and productivity, and the common bucket capacity options for different excavator models. Let's dive in!

Relationship Between Excavator Size and Bucket Capacity

When it comes to excavators, size matters – and it directly impacts the excavator bucket capacity. Generally speaking, a larger excavator cab can accommodate larger buckets, which in turn allows for greater digging capacity. This relationship is crucial for contractors and project managers to understand when selecting the right equipment for their job sites.

The size of an excavator is typically measured by its operating weight, which can range from mini excavators weighing just a few tons to massive mining excavators weighing hundreds of tons. As the excavator's size increases, so does its ability to handle larger buckets and move more material per scoop.

For example, a compact excavator in the 3-5 ton range might have an excavator bucket capacity of 0.1 to 0.3 cubic meters, while a medium-sized excavator in the 20-30 ton range could handle a bucket with a capacity of 1 to 2 cubic meters. Large excavators used in mining operations can have bucket capacities exceeding 30 cubic meters.

It's important to note that the relationship between excavator size and bucket capacity is not always linear. Factors such as the excavator's hydraulic power, boom and arm configuration, and intended application also play a role in determining the optimal size for a given machine.

How Does Bucket Capacity Affect Excavation Efficiency and Productivity?

The bucket capacity of an excavator cab has a significant impact on its excavation efficiency and overall productivity. A larger excavator bucket allows the operator to move more material with each cycle, potentially reducing the time required to complete a job. However, it's not always as simple as "bigger is better." Several factors come into play when considering the relationship between bucket capacity and efficiency:

- Material density: The type of material being excavated affects the optimal size. Lighter materials like dry soil or sand can be moved with larger buckets, while denser materials like wet clay or rock may require smaller buckets to avoid overloading the machine.

- Cycle times: While a larger bucket can move more material per scoop, it may also increase cycle times due to the additional weight and the need for more precise positioning. This can potentially offset some of the productivity gains.

- Fuel efficiency: Larger buckets require more power to operate, which can lead to increased fuel consumption. Project managers must balance the benefits of increased capacity with the associated fuel costs.

- Maneuverability: A smaller excavator bucket may allow for greater precision and maneuverability in tight spaces or when working around obstacles, potentially improving overall efficiency.

- Operator skill: The efficiency gains from a larger bucket capacity can only be fully realized with a skilled operator who can handle the increased load and maintain smooth, efficient cycles.

To maximize excavation efficiency and productivity, it's crucial to select the right excavator bucket capacity for the specific job requirements and excavator model. This often involves finding a balance between capacity, maneuverability, and the characteristics of the material being excavated.

Common Bucket Capacity Options for Different Excavator Models

Excavator manufacturers offer a range of bucket capacity options to suit different machine sizes and applications. Here's an overview of common excavator bucket capacities for various excavator models:

- Mini excavators (1-6 tons): 0.02 to 0.3 cubic meters

- Compact excavators (6-10 tons): 0.15 to 0.6 cubic meters

- Mid-size excavators (10-30 tons): 0.5 to 2 cubic meters

- Large excavators (30-50 tons): 1.5 to 3.5 cubic meters

- Heavy excavators (50+ tons): 3 to 6+ cubic meters

It's important to note that these ranges are approximate and can vary depending on the manufacturer and specific model. Additionally, many excavator models offer interchangeable buckets, allowing operators to switch between different capacities and styles based on the task at hand [3].

Some specialized bucket types include:

- General purpose buckets: Suitable for a wide range of materials and applications

- Rock buckets: Designed with reinforced edges and teeth for handling rocky terrain

- Trenching buckets: Narrow buckets optimized for digging trenches

- Skeleton buckets: Feature openings that allow small debris to fall through, ideal for sorting materials

- Tilt buckets: Can be angled for precise grading and slope work

When selecting a bucket for an excavator, it's essential to consider not only the capacity but also the type of bucket that best suits the intended application. This ensures optimal performance and efficiency on the job site.

China Excavator Cab Manufacturers

If you're in the market for a high-quality excavator bucket, consider the offerings from Shandong Tiannuo Engineering Machinery Co., Ltd. Our bucket is crafted from high-strength wear-resistant steel to ensure durability and longevity. With a capacity ranging from 0.1 to 5.0 cubic meters and a weight between 100 and 2000 kg, it's designed to meet diverse excavation needs. The width varies from 500 to 2000 mm, making it versatile for various job sites. Customization is available to fit your specific requirements. Compatible with a wide range of excavator models, it offers pin-on or quick coupler attachment types for easy installation. Safety is a priority, with reinforced edges and wear plates for added protection. Upgrade your excavation efficiency and precision with our products today!

If you're looking for a reliable manufacturer, we invite you to reach out to our team. Contact our manager at arm@stnd-machinery.com or our sales team at rich@stnd-machinery.com and tn@stnd-machinery.com for more information on our products and how we can meet your specific needs.

References

- Caterpillar Inc. (2021). Excavator Size Classes and Bucket Capacities. Cat.com

- Volvo Construction Equipment. (2020). Excavator Productivity: Balancing Bucket Size and Cycle Times. Volvoce.com

- Komatsu Ltd. (2022). Excavator Bucket Selection Guide. Komatsu.com

YOU MAY LIKE

VIEW MOREHigh-vibration hydraulic ballast tamping machine

VIEW MOREHigh-vibration hydraulic ballast tamping machine VIEW MOREExcavator Gripper

VIEW MOREExcavator Gripper VIEW MOREExcavator Wood Clamps

VIEW MOREExcavator Wood Clamps VIEW MOREExcavator Special-Shaped Bucket

VIEW MOREExcavator Special-Shaped Bucket VIEW MOREExcavator High Frequency Screening Bucket

VIEW MOREExcavator High Frequency Screening Bucket VIEW MOREClamshell Bucket

VIEW MOREClamshell Bucket VIEW MOREExcavator High Altitude Demolition Arm

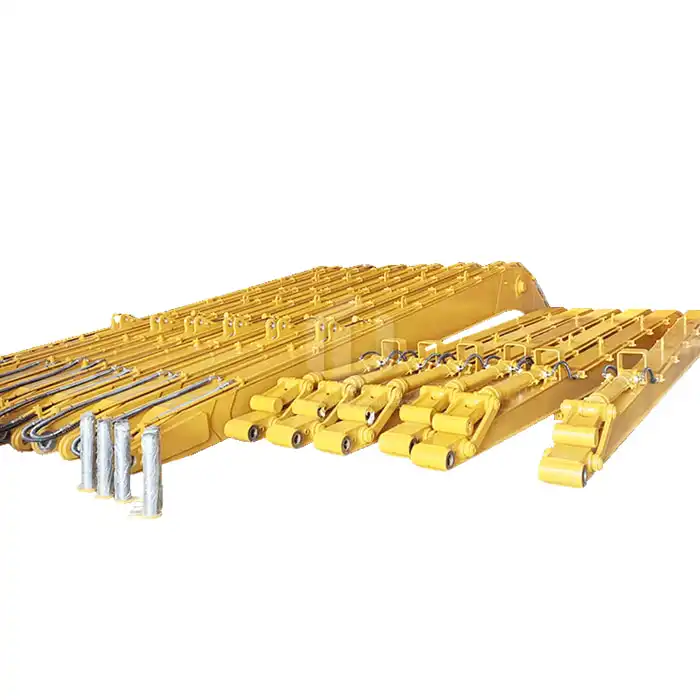

VIEW MOREExcavator High Altitude Demolition Arm VIEW MOREExcavator Extension Arm

VIEW MOREExcavator Extension Arm