What is an excavator wood clamp?

In the world of heavy machinery and forestry operations, efficiency and precision are paramount. One tool that has revolutionized the handling of timber and logs is the excavator wood clamp. These versatile attachments have become indispensable in various industries, from logging to construction. In this comprehensive guide, we'll explore the ins and outs of excavator wood clamps, their types, materials, and applications.

What is an excavator wood clamp?

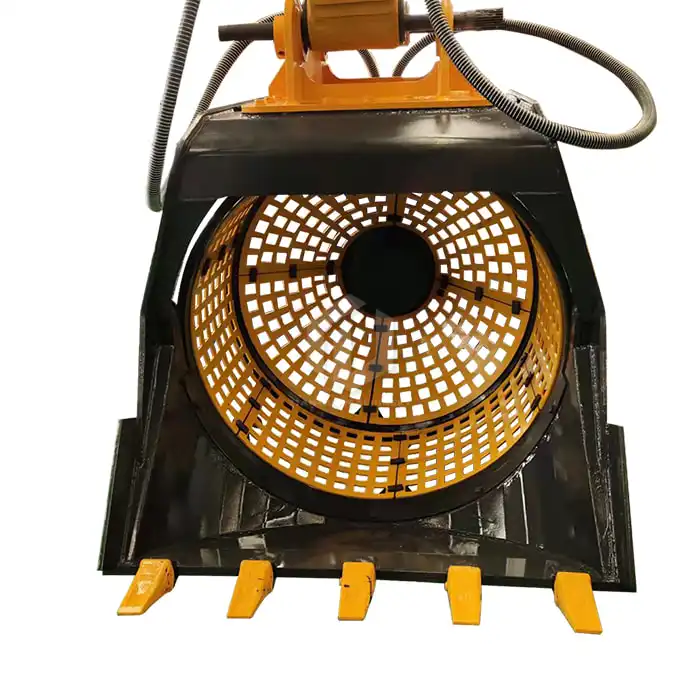

An excavator wood clamp, also known as a log grapple or timber grab, is a specialized attachment designed to be fitted onto an excavator. This powerful tool is engineered to securely grip, lift, and transport logs, trees, and other wooden materials with ease and precision. The clamp consists of two or more hydraulically operated arms that can open and close, allowing for a firm grip on various sizes of timber.

The primary function is to enhance the versatility and efficiency of excavators in forestry and logging operations. By replacing the standard bucket with a wood clamp, operators can easily handle logs, clear brush, and stack timber without the need for additional equipment or manual labor. This not only saves time but also significantly improves safety on job sites.

Excavator wood clamps come in various sizes and configurations to suit different excavator models and specific job requirements. The size of the clamp is typically matched to the size and lifting capacity of the excavator, ensuring optimal performance and safety. Some clamps are designed with rotating mechanisms, allowing for 360-degree rotation, which further enhances their versatility and precision in handling timber.

What are the main types of excavator wood clamps?

Excavator wood clamps come in several types, each designed for specific applications and logging conditions. Understanding these variations can help you choose the right clamp for your particular needs:

- Sorting Grapples: These are versatile clamps ideal for handling and sorting logs of various sizes. They typically have wide openings and can handle multiple logs simultaneously, making them perfect for loading trucks or sorting at lumber yards.

- Demolition Grapples: While not exclusively for wood, these robust clamps are excellent for handling mixed materials, including wood debris in demolition sites. They often have reinforced tines to withstand the rigors of demolition work.

- Bypass Grapples: These clamps feature overlapping tines that "bypass" each other when closed, allowing for a secure grip on smaller diameter logs or branches. They're particularly useful in thinning operations or handling irregularly shaped timber.

- Power Clamps: These are heavy-duty clamps designed for handling large, heavy logs. They often come with additional features like 360-degree rotation and high clamping force, making them suitable for demanding logging operations.

- Rake Grapples: These combine the features of a rake and a grapple, allowing for clearing brush and small trees while also being able to grip and move larger logs.

Each type of excavator wood clamp offers unique advantages, and the choice often depends on the specific requirements of the job, the type of timber being handled, and the capabilities of the excavator itself. Some manufacturers also offer customizable options, allowing users to tailor the clamp to their exact needs.

What materials are used in manufacturing excavator wood clamps?

The durability and performance of excavator wood clamps largely depend on the materials used in their construction. Manufacturers carefully select materials that can withstand the harsh conditions of logging and forestry operations while maintaining optimal functionality. Here are some of the key materials used in the production of high-quality excavator wood clamps:

- High-Strength Steel: The main body and arms of the clamp are typically made from high-strength steel alloys. These alloys offer an excellent balance of strength, durability, and weight, allowing the clamp to handle heavy loads without excessive wear or deformation.

- Hardened Steel: The gripping surfaces or tines of the clamp are often made from hardened steel. This material provides superior wear resistance and maintains its shape even under high pressure and frequent use.

- Wear-Resistant Plates: Many manufacturers incorporate wear-resistant plates in high-friction areas of the clamp. These plates, often made from materials like Hardox or other specialized alloys, help extend the life of the clamp by reducing wear and tear.

- High-Grade Hydraulic Components: The hydraulic cylinders, hoses, and fittings that control the clamp's movement are made from high-quality materials designed to withstand high pressures and prevent leaks.

- Reinforced Pivot Points: The pivot points of the clamp, which undergo significant stress during operation, are often reinforced with hardened steel bushings or bearings to ensure smooth operation and longevity.

- Protective Coatings: Many wood clamps are treated with protective coatings or paint to resist corrosion and withstand exposure to various weather conditions.

The choice of materials can significantly impact the performance, durability, and cost of an excavator wood clamp. High-quality materials may increase the initial cost but often result in lower maintenance needs and a longer operational life, providing better value in the long run.

What industries commonly use excavator wood clamps?

Excavator wood clamps have found applications across various industries due to their versatility and efficiency in handling timber and wooden materials. Here are some of the key industries that frequently utilize these attachments:

- Forestry and Logging: This is the primary industry for wood clamps. They are used for felling trees, sorting logs, loading timber onto trucks, and clearing forest areas.

- Construction: In construction sites, these clamps are used for clearing land, handling wooden construction materials, and managing waste wood from demolition projects.

- Recycling and Waste Management: Wood clamps are useful in recycling facilities for sorting and handling wooden waste materials, aiding in the recycling process.

- Landscaping: Large-scale landscaping projects often use excavator wood clamps for tree removal, brush clearing, and handling large branches or logs.

- Sawmills and Lumber Yards: These facilities use wood clamps for sorting, stacking, and moving logs and processed timber.

- Port Operations: In ports handling timber exports or imports, wood clamps are used for loading and unloading ships and organizing log storage areas.

- Agriculture: Some agricultural operations, particularly those involving orchard management or land clearing, utilize excavator wood clamps.

- Disaster Response: In the aftermath of natural disasters like hurricanes or floods, these clamps are used for clearing fallen trees and wooden debris.

The versatility of excavator wood clamps makes them valuable assets in any industry that deals with large-scale handling of wood or timber. As technology advances, we're likely to see these tools become even more efficient and find applications in additional sectors.

Excavator Wood Clamps Supplier

Tiannuo Machinery offers a wide range of excavator wood clamps designed to meet various operational needs. Their product line includes: from 3-5 Ton to 41-45 Ton excavators. If you're in the market for a reliable excavator wood clamp manufacturer, we invite you to reach out to Tiannuo Machinery. Our team is ready to assist you in finding the perfect solution for your operational needs. Contact our manager at arm@stnd-machinery.com, or our team members at rich@stnd-machinery.com and tn@stnd-machinery.com. Let us help you enhance your operations with our high-quality excavator wood clamps.

References

- Forest Engineering Research Institute of Canada. (2018). "Grapple types and applications in forestry operations."

- Journal of Forest Engineering. (2020). "Advancements in Excavator Attachments for Timber Handling."

- International Journal of Forest Engineering. (2019). "Material Sciences in Forestry Equipment Manufacturing."

- Forestry Equipment Review. (2021). "Industry Applications of Hydraulic Grapples and Clamps."

YOU MAY LIKE

VIEW MOREExcavator Railway Slope Cleaning Machine

VIEW MOREExcavator Railway Slope Cleaning Machine VIEW MOREExcavator rail clamp

VIEW MOREExcavator rail clamp VIEW MOREExcavator Rotating Scraper

VIEW MOREExcavator Rotating Scraper VIEW MOREExcavator Rotary Screening Bucket

VIEW MOREExcavator Rotary Screening Bucket VIEW MOREExcavator Grab Arm

VIEW MOREExcavator Grab Arm VIEW MOREExcavator High Altitude Demolition Arm

VIEW MOREExcavator High Altitude Demolition Arm VIEW MORERailway Excavator Cleaning Bucket

VIEW MORERailway Excavator Cleaning Bucket VIEW MOREExcavator Screening Bucket

VIEW MOREExcavator Screening Bucket