What are the different types of excavator rippers?

Excavator rippers are essential attachments in the construction and mining industries, designed to break up hard soil, rock, or frozen ground. These powerful tools enhance the versatility and efficiency of excavators, allowing them to tackle challenging terrains and materials. In this comprehensive guide, we'll explore the various types of rippers, their design features, and how they work to make excavation tasks more manageable.

Number of Teeth

One of the primary factors that differentiate excavator rippers is the number of teeth they possess. The tooth configuration plays a crucial role in determining the ripper's effectiveness and suitability for different applications. Let's examine the most common types based on tooth count:

Single-tooth Rippers

Single-tooth rippers, as the name suggests, feature a single, robust tooth. These are the most common type of excavator rippers and are particularly effective for breaking up hard, compacted soil or rock. The concentrated force applied through a single point allows for maximum penetration and efficiency in tough materials. Single-tooth rippers are ideal for:

- Breaking up bedrock

- Ripping through frozen ground

- Excavating in areas with large boulders

- General-purpose ripping in various soil conditions

The simplicity of the single-tooth design also makes these rippers easier to maintain and replace when worn. However, they may be less effective in softer materials or when a wider ripping area is required.

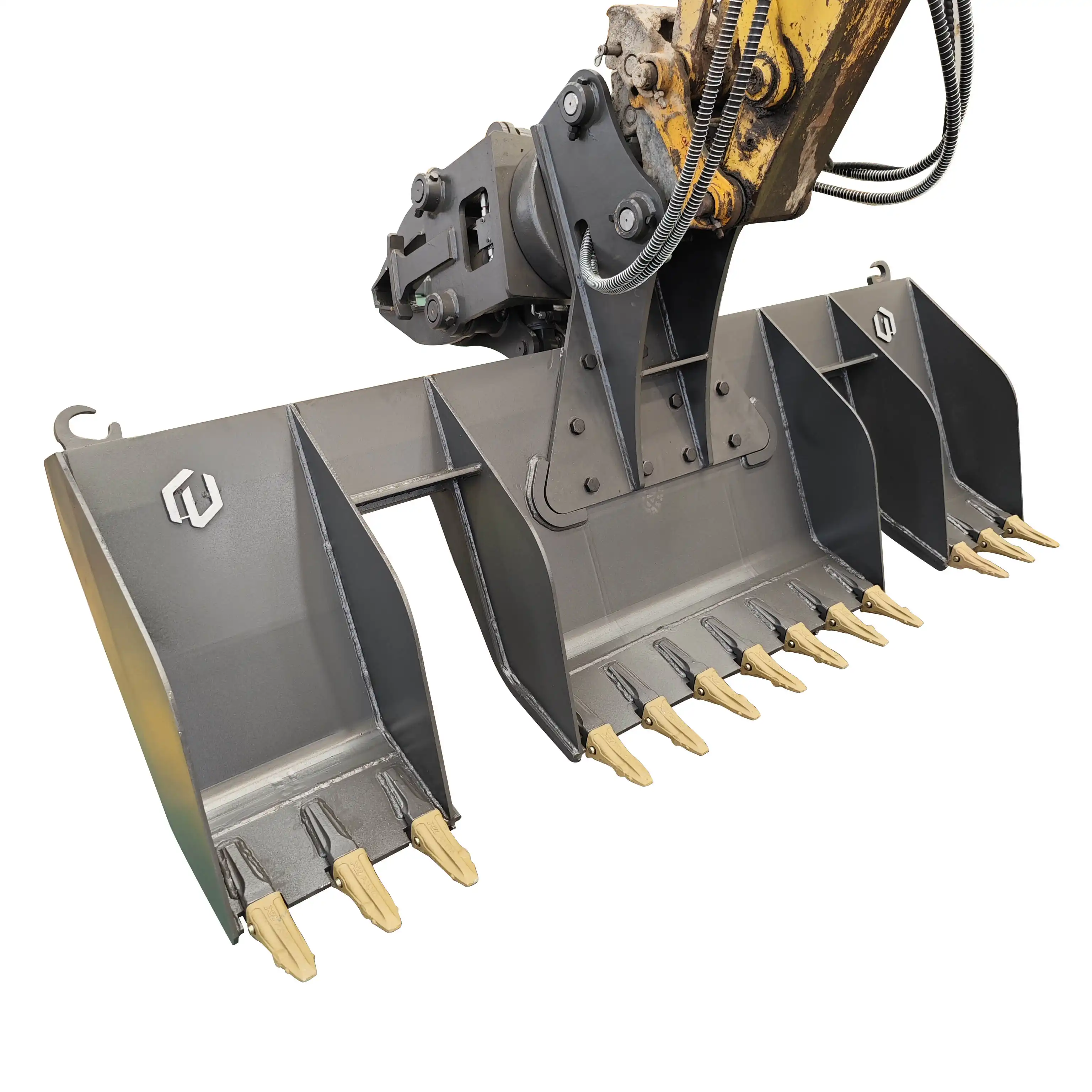

Multi-tooth Rippers

Multi-tooth rippers typically feature two to five teeth and are designed for situations where a broader ripping area is beneficial. These rippers are particularly useful in:

- Softer soil conditions

- Ripping larger surface areas

- Breaking up asphalt or concrete

- Preparing ground for landscaping

The multiple teeth allow for more even distribution of force across a wider area, which can be advantageous in certain applications. However, they may not penetrate as deeply as single-tooth rippers in extremely hard materials.

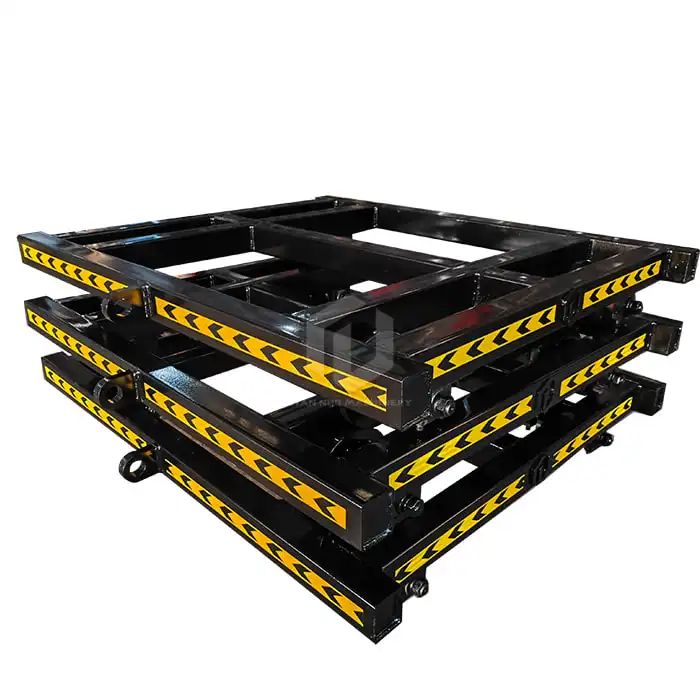

Adjustable Rippers

Some advanced excavator rippers feature adjustable tooth configurations. These versatile attachments allow operators to add or remove teeth based on the specific requirements of the job. Adjustable rippers provide the flexibility to switch between single-tooth and multi-tooth configurations, making them adaptable to various soil conditions and project needs.

The ability to adjust the number of teeth can significantly enhance the excavator's versatility, allowing it to tackle a wide range of ripping tasks without the need for multiple attachments.

Design and Purpose

Excavator rippers come in various designs, each tailored to specific purposes and soil conditions. Understanding these designs can help in selecting the most appropriate ripper for a given task.

Standard Rippers

Standard rippers are the most common and versatile type. They typically feature a curved shank with a replaceable tooth or teeth at the end. The curved design helps in penetrating the ground and lifting material as the excavator moves backward. Standard rippers are suitable for a wide range of applications, from breaking up moderately hard soil to ripping through frozen ground.

Heavy-duty Rippers

Heavy-duty rippers are designed for the toughest excavation tasks. They feature reinforced shanks and more robust teeth to withstand the extreme forces encountered when ripping through hard rock or heavily compacted soil. These rippers often have additional wear protection and may be made from higher-grade materials to ensure longevity in demanding conditions.

Frost Rippers

Frost rippers are specialized attachments designed specifically for breaking through frozen ground. They often feature a more aggressive tooth angle and may have additional features to prevent material buildup in cold conditions. Frost rippers are essential for maintaining productivity in regions with harsh winters or in applications where frozen ground is frequently encountered.

Multi-purpose Rippers

Some excavator rippers are designed to serve multiple purposes. These attachments may combine ripping capabilities with other functions, such as grading or root raking. Multi-purpose rippers can be especially useful for contractors looking to maximize the versatility of their equipment while minimizing the need for multiple attachments.

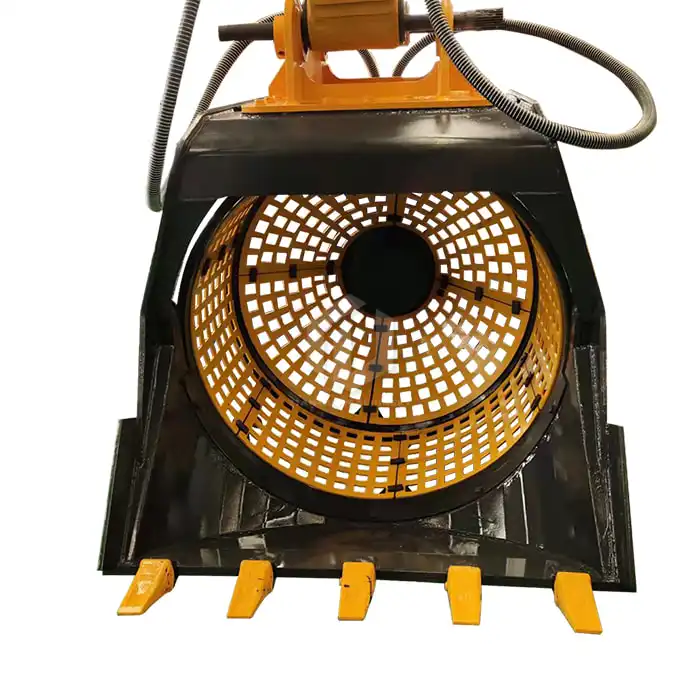

Hydraulic Rippers

Hydraulic rippers represent the cutting edge of excavator ripper technology. These advanced attachments use hydraulic power to enhance ripping performance. Some hydraulic rippers can vibrate or oscillate, which can significantly improve penetration in hard materials and increase overall efficiency. While more complex and typically more expensive, hydraulic rippers can offer substantial productivity gains in challenging conditions.

Working Principle

Understanding how excavator rippers work is crucial for their effective use and maintenance. The working principle of these attachments is based on a combination of mechanical force, leverage, and the excavator's power.

Force Application

The primary working principle of an excavator ripper is the application of concentrated force. As the excavator's arm moves, it drives the ripper's tooth or teeth into the material being excavated. The sharp, hardened tip of the tooth penetrates the surface, creating an initial fracture point.

Leverage and Prying Action

Once the tooth has penetrated the material, the operator uses the excavator's arm to apply leverage. By manipulating the arm's position and angle, the operator can create a prying action that helps to break apart the material. This combination of downward force and leveraged prying is particularly effective in breaking up rock or hard soil.

Material Displacement

As the ripper moves through the material, it displaces and lifts it, creating fractures and loosening the ground. This action makes it easier for the excavator bucket to scoop up the loosened material in subsequent passes. In multi-tooth rippers, the teeth work together to create broader channels or furrows in the material.

Vibration and Shock Absorption

Modern excavator rippers often incorporate design features to manage the vibration and shock generated during ripping operations. This can include flexible mounting systems or built-in shock absorbers that help protect both the attachment and the excavator from excessive stress.

Hydraulic Enhancement

In hydraulic rippers, the working principle is further enhanced by the addition of hydraulic power. This can manifest in various ways:

- Vibratory action to improve penetration

- Adjustable tooth angles for optimal engagement

- Hydraulic clamping for secure attachment to different materials

The hydraulic systems in these advanced rippers can significantly increase the efficiency and versatility of the ripping operation.

Excavator Ripper For Sale

Tiannuo Machinery's excavator rippers boast strong digging and cutting abilities, making them ideal for a wide range of applications. They are particularly convenient for loosening sections of hard soil or rock, effectively separating materials to reduce cutting resistance. This feature not only enhances productivity but also minimizes wear on the equipment.

One of the key advantages of Tiannuo's rippers is their user-friendly design. The rippers are easily disassembled and replaced, which significantly prolongs their lifespan and reduces maintenance downtime. This feature is especially valuable for projects with tight deadlines or in remote locations where equipment reliability is crucial.

Technically, Tiannuo Machinery offers a diverse range of rippers designed for various working weights and material strengths. Their product line includes rippers for machines ranging from 3-5T to 31-35T, ensuring that there's a suitable option for nearly every size of excavator. The rippers vary in board thickness and materials, allowing customers to select the perfect match for their specific operational needs and ground conditions.

If you're in the market for a reliable, efficient, and durable excavator ripper, Tiannuo Machinery should be at the top of your list. Their commitment to quality and customer satisfaction is evident in every product they offer. To explore their range of excavator rippers or to discuss your specific needs, don't hesitate to reach out to their expert team.

For personalized assistance and detailed product information, you can contact their manager directly at arm@stnd-machinery.com. Additionally, their dedicated team members are available at rich@stnd-machinery.com and tn@stnd-machinery.com. Take the first step towards enhancing your excavation capabilities by getting in touch with Tiannuo Machinery today.

References

- Smith, J. (2021). "Excavator Attachments: A Comprehensive Guide." Construction Equipment Magazine, 45(3), 78-85.

- Johnson, R. (2020). "Advanced Ripping Techniques in Hard Rock Excavation." Mining Engineering, 72(8), 42-50.

- Brown, A. (2019). "Hydraulic Excavator Attachments: Innovations and Applications." Journal of Construction Engineering, 15(2), 123-135.

- Wilson, M. (2022). "Frost Ripping: Techniques for Excavation in Cold Climates." Arctic Engineering Quarterly, 33(1), 67-74.

- Davis, L. (2018). "Maintenance Strategies for Excavator Attachments." Heavy Equipment Maintenance Journal, 28(4), 92-101.