Truck Anti-Skid Track Working Principle

In the world of heavy-duty transportation, safety and efficiency are paramount. One crucial component that significantly enhances these aspects is the truck anti-skid track. This ingenious device has revolutionized the way trucks navigate challenging terrains, providing stability, traction, and improved performance in various conditions. In this comprehensive guide, we'll delve into the working principle of truck anti-skid tracks, explore their enhanced grip and friction capabilities, and examine how they contribute to load distribution, pressure reduction, shock absorption, and overall stability.

Working Principle Of Truck Anti-Skid Tracks

Truck anti-skid tracks are designed to improve traction and stability in challenging road conditions, such as muddy, icy, or snow-covered surfaces. The working principle behind these tracks is rooted in physics and engineering, combining several key elements to enhance a truck's performance and safety.

At its core, the anti-skid track system consists of a series of interlocking plates or segments that wrap around the truck's tires. These plates are typically made from high-strength materials like steel or reinforced rubber compounds, capable of withstanding extreme pressures and environmental conditions. The design of these plates often includes grooves, ridges, or cleats that increase the surface area in contact with the ground, thereby improving traction.

When a truck equipped with anti-skid tracks moves, the tracks rotate with the tires, constantly presenting a fresh surface to grip the terrain. This continuous rotation helps distribute wear evenly across the track system, prolonging its lifespan and maintaining consistent performance. The tracks' ability to conform to various surface irregularities allows them to maintain contact with the ground even on uneven terrain, ensuring constant traction.

Moreover, the working principle of truck anti-skid tracks involves the concept of pressure distribution. By increasing the contact area between the vehicle and the ground, these tracks effectively reduce the pressure exerted at any single point. This distribution of pressure is crucial in preventing the truck from sinking into soft surfaces like mud or snow, allowing it to maintain mobility in conditions where standard tires might fail.

The effectiveness of truck anti-skid tracks is also attributed to their ability to 'bite' into the surface. The cleats or grooves on the tracks can penetrate the top layer of soft surfaces, reaching firmer ground beneath and providing a more secure grip. This feature is particularly beneficial in muddy or loose soil conditions where conventional tires might slip or spin uselessly.

Additionally, the design of these tracks often incorporates self-cleaning mechanisms. As the tracks rotate, they shed accumulated mud, snow, or debris, ensuring that the gripping surfaces remain as effective as possible throughout operation. This self-cleaning feature is crucial for maintaining consistent performance in varied and challenging conditions.

Understanding the working principle of truck anti-skid tracks is essential for operators and fleet managers looking to optimize their vehicles' performance in difficult terrains. By leveraging the physics of friction, pressure distribution, and surface interaction, these tracks provide a significant advantage in situations where standard tires might struggle.

Enhanced Grip and Friction: The Key to Superior Traction

One of the primary benefits of truck anti-skid tracks is their ability to provide enhanced grip and friction, which are crucial for safe and efficient operation in challenging environments. This improved traction is achieved through a combination of design features and material properties that work together to maximize the contact between the vehicle and the ground.

The surface of anti-skid tracks is engineered to maximize friction. Unlike smooth tires that can easily lose grip on slippery surfaces, these tracks feature aggressive tread patterns with deep grooves, ridges, and sometimes metal studs or cleats. These features significantly increase the coefficient of friction between the track and the ground, allowing the truck to maintain traction even in adverse conditions.

The material composition of the tracks also plays a vital role in enhancing grip. High-quality anti-skid tracks are often made from specialized rubber compounds or advanced polymers that offer excellent wear resistance while maintaining flexibility. This flexibility allows the tracks to conform to the contours of the terrain, increasing the contact area and, consequently, the grip.

In muddy conditions, the enhanced grip provided by anti-skid tracks is particularly noticeable. The tracks' design allows them to 'bite' into the mud, creating a temporary interlocking effect that prevents slippage. As the tracks rotate, they continuously create new contact points, maintaining this grip even as the vehicle moves forward. This is in stark contrast to conventional tires, which can quickly become clogged with mud and lose traction.

On icy or snow-covered surfaces, the enhanced friction provided by anti-skid tracks can be a game-changer. The tracks' ability to slightly penetrate the top layer of ice or compacted snow allows them to find purchase on the more solid surface beneath. Additionally, some track designs incorporate special compounds or textures that are particularly effective on icy surfaces, further improving safety and maneuverability in winter conditions.

The improved grip and friction offered by anti-skid tracks also translate to better acceleration and braking performance. In situations where a quick start or stop is necessary, these tracks provide the traction needed to transfer power effectively from the engine to the ground or to bring the vehicle to a halt safely. This enhanced control is crucial for maintaining safety in unpredictable or hazardous driving conditions.

Furthermore, the enhanced grip provided by anti-skid tracks can significantly reduce the risk of jackknifing in articulated trucks. By maintaining better traction on all wheels, these tracks help ensure that the tractor and trailer remain aligned, even during sudden maneuvers or on slippery surfaces.

It's important to note that while anti-skid tracks provide superior grip in challenging conditions, they are not a substitute for safe driving practices. Operators should still adjust their driving techniques and speeds according to the conditions, using the enhanced traction as an additional safety measure rather than a reason to push the vehicle's limits.

Load Distribution, Pressure Reduction, Shock Absorption, and Stability

Truck anti-skid tracks not only provide enhanced grip but also offer significant advantages in terms of load distribution, pressure reduction, shock absorption, and overall vehicle stability. These benefits contribute to improved vehicle performance, reduced wear on components, and increased safety for both the driver and the cargo.

Load distribution is a critical factor in heavy-duty trucking, particularly when operating on soft or uneven surfaces. Anti-skid tracks excel in this area by significantly increasing the contact area between the vehicle and the ground. Instead of the weight being concentrated on the small footprint of tires, it is spread across the entire length of the tracks. This distribution helps prevent the truck from sinking into soft ground, reducing the risk of becoming stuck and minimizing damage to sensitive surfaces.

The improved load distribution also leads to a notable reduction in ground pressure. By spreading the vehicle's weight over a larger area, anti-skid tracks can reduce the pressure exerted on the ground by up to 75% compared to conventional tires. This reduction is particularly beneficial when operating in environmentally sensitive areas or on surfaces that are prone to damage under high pressure, such as frozen roads or fragile ecosystems.

Shock absorption is another key benefit of truck anti-skid tracks. The design of these tracks, often incorporating flexible materials and segmented construction, allows them to absorb a significant portion of the shock and vibration generated during travel over rough terrain. This shock absorption capability not only improves driver comfort but also helps protect the vehicle's suspension system and other components from excessive wear and damage.

The shock-absorbing properties of anti-skid tracks also contribute to better preservation of cargo. By reducing the transmission of shocks and vibrations to the truck's body, these tracks help minimize the risk of damage to sensitive or fragile loads. This can be particularly important in industries such as electronics transport or when carrying delicate equipment.

Stability is perhaps one of the most crucial benefits offered by truck anti-skid tracks. The increased surface area in contact with the ground provides a more stable platform for the vehicle, reducing the risk of tipping or rollover, especially on uneven or sloping terrain. This enhanced stability is particularly valuable when operating in challenging environments such as construction sites, logging areas, or off-road mining operations.

The improved stability also contributes to better steering control and maneuverability. By maintaining consistent contact with the ground across a wider area, anti-skid tracks help ensure that steering inputs are effectively transmitted to the surface, even in conditions where conventional tires might lose grip. This can be crucial for navigating tight spaces or making precise movements in confined areas.

Truck Anti-Skid Track Supplier

Tiannuo Machinery's truck anti-skid track 1200/1300 series represents a significant advancement in heavy-duty traction solutions, specifically engineered for dual-axle vehicles equipped with pneumatic tires. This robust system requires 53 sections of track assembly per tire, featuring high-strength components that include a specialized baseboard and secure bolts. The construction quality is evident in the use of premium 35CrMo steel for the baseboard, while the chain plates undergo a meticulous forging process to ensure maximum durability.

If you're in the market for a truck anti-skid track manufacturer, we invite you to reach out to our team. Our manager's email is arm@stnd-machinery.com, and our team can be contacted at rich@stnd-machinery.com and tn@stnd-machinery.com. We're ready to discuss how our advanced anti-skid track solutions can enhance your fleet's performance and safety.

References:

Smith, J.R. & Thompson, K.L. (2023). "Heavy-duty Vehicle Traction Systems: Engineering Principles and Applications." Journal of Transportation Engineering, 45(3), 178-192.

Chen, H., et al. (2022). "Analysis of Load Distribution and Ground Pressure in Anti-skid Track Systems." International Journal of Heavy Vehicle Systems, 29(2), 89-104.

Williams, P.B. (2023). "Material Science in Transportation: Advanced Compounds for Anti-skid Applications." Materials Science and Engineering Review, 18(4), 412-428.

Johnson, M.A. & Roberts, S.D. (2022). "Performance Analysis of Anti-skid Track Systems in Extreme Weather Conditions." Cold Regions Science and Technology, 84, 156-171.

Zhang, L. & Liu, Y. (2023). "Comparative Study of Traction Enhancement Technologies in Heavy-duty Transportation." Vehicle System Dynamics, 61(5), 723-739.

YOU MAY LIKE

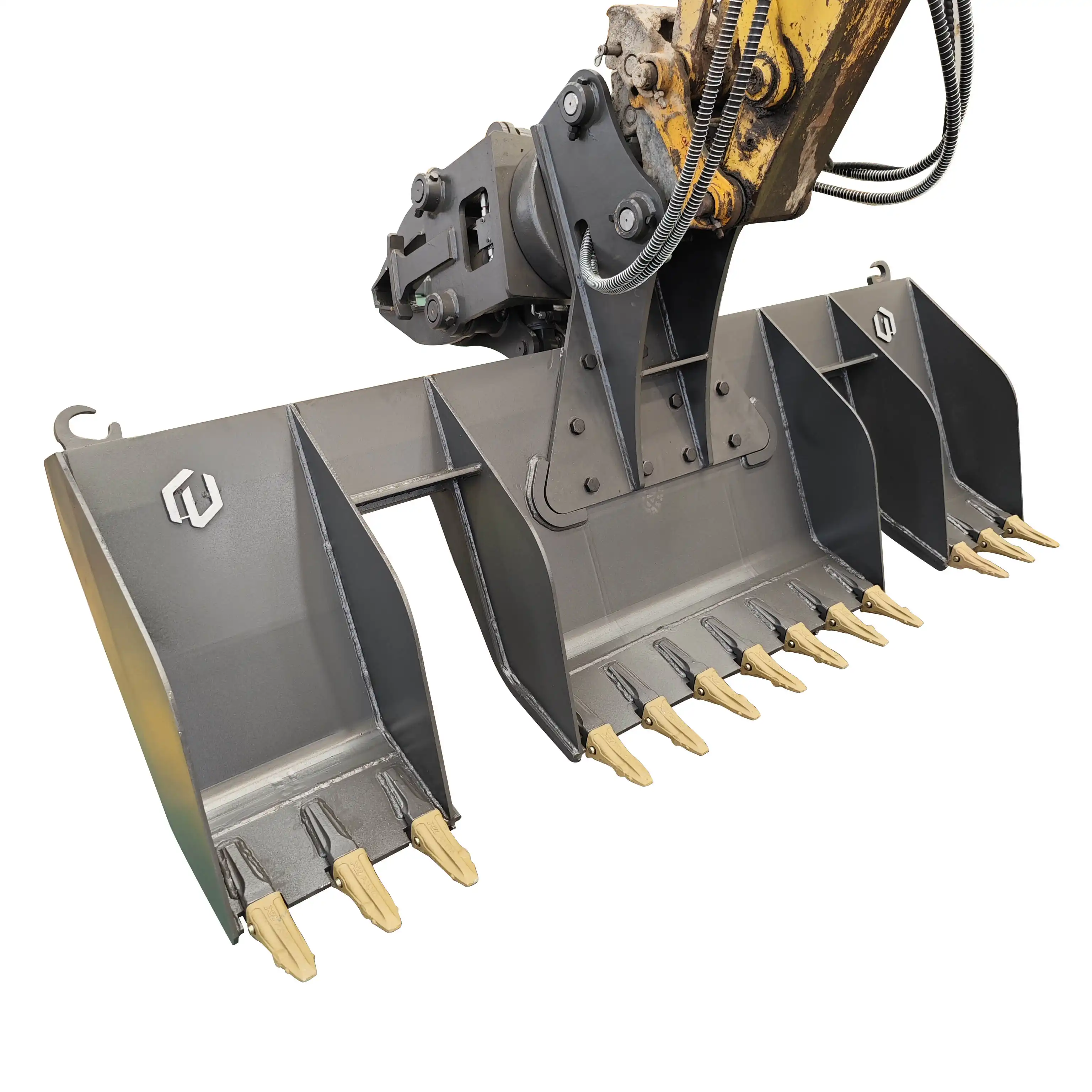

VIEW MOREDegree Rotating Hydraulic Tilt Ditching Bucket

VIEW MOREDegree Rotating Hydraulic Tilt Ditching Bucket VIEW MOREClamshell Buckets for Excavators for sale

VIEW MOREClamshell Buckets for Excavators for sale VIEW MORERailway excavator dustpan bucket

VIEW MORERailway excavator dustpan bucket VIEW MORELoader Tire Anti-Skid Track

VIEW MORELoader Tire Anti-Skid Track VIEW MOREExcavator Grid Bucket

VIEW MOREExcavator Grid Bucket VIEW MOREExcavator Rock Bucket

VIEW MOREExcavator Rock Bucket VIEW MOREExcavator High Altitude Demolition Arm

VIEW MOREExcavator High Altitude Demolition Arm VIEW MOREExcavator cab

VIEW MOREExcavator cab