Front Loader Bucket Capacity

Front loader buckets are essential attachments for various construction and earthmoving equipment. These versatile tools are designed to scoop, carry, and dump materials efficiently, making them indispensable in industries ranging from construction and mining to agriculture and waste management. Understanding its capacity is crucial for optimizing productivity and ensuring that the right equipment is used for the job at hand. Shandong Tiannuo explores the factors that determine front loader bucket capacity, how to choose the right capacity for your loader, and how bucket capacity varies across different industries.

What Factors Determine Front Loader Bucket Capacity?

Several key factors influence the capacity of a front loader bucket. Understanding these elements is essential for both manufacturers and end-users to ensure that the bucket meets the specific requirements of the task at hand.

1. Bucket Size and Design

The physical dimensions of the bucket, including its length, width, and depth, play a significant role in determining its capacity. Bucket designs can vary, with some featuring a flat bottom for better material retention, while others have a curved bottom for easier dumping. The shape of the bucket sides and the presence of side cutters also affect capacity and performance.

2. Material Density

The type of material being handled significantly impacts the effective capacity of a front loader bucket. Lighter materials like snow or mulch allow for larger bucket volumes, while denser materials such as rock or wet soil require smaller buckets to prevent overloading the machine.

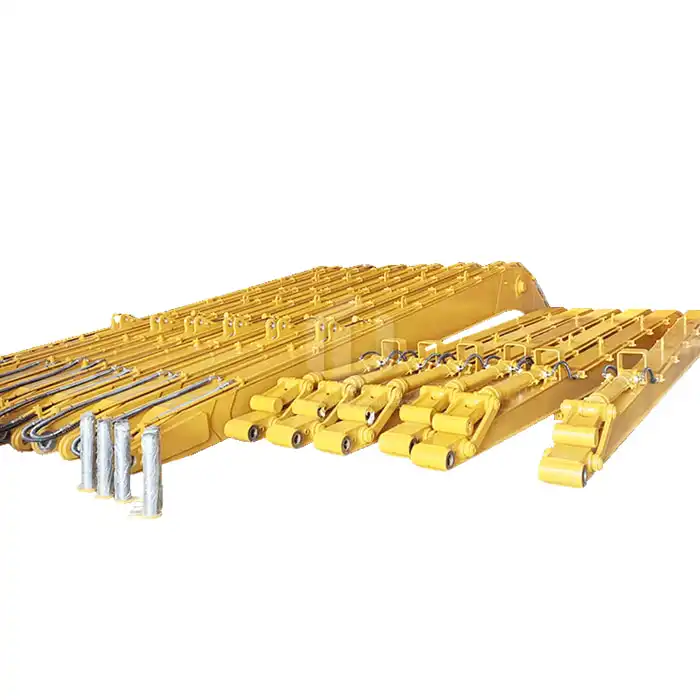

3. Loader Specifications

The specifications of the loader itself, including its size, hydraulic lift capacity, and tipping load, directly influence the maximum bucket capacity that can be safely used. Larger loaders can accommodate larger buckets, but it's crucial to ensure that the bucket doesn't exceed the machine's operational capabilities.

4. Bucket Material

The material used to construct the bucket affects its weight and durability. Lighter materials like aluminum may allow for slightly larger bucket sizes without exceeding the loader's weight limits, while heavier, more durable materials like steel might require a smaller bucket to maintain optimal performance.

5. Application Requirements

The specific needs of the job site or industry can dictate bucket capacity. For instance, precision work might require smaller buckets for better control, while high-volume operations may benefit from larger capacities to improve efficiency.

How to Choose the Right Bucket Capacity for Your Loader?

Selecting the appropriate front loader bucket capacity is crucial for maximizing productivity and ensuring the longevity of your equipment. Here are some key considerations to help you make an informed decision:

1. Assess Your Operational Needs

Begin by evaluating the typical materials you'll be handling and the volume of work required. Consider factors such as the density of materials, the frequency of loading cycles, and any space constraints at your work site. This assessment will help you determine the ideal bucket capacity range for your operations.

2. Consider Your Loader's Specifications

Review your loader's technical specifications, paying close attention to its lifting capacity, tipping load, and hydraulic flow rate. The bucket capacity should be well within these limits to ensure safe and efficient operation. It's generally recommended to choose a bucket that, when fully loaded, does not exceed 50% of the loader's tipping load.

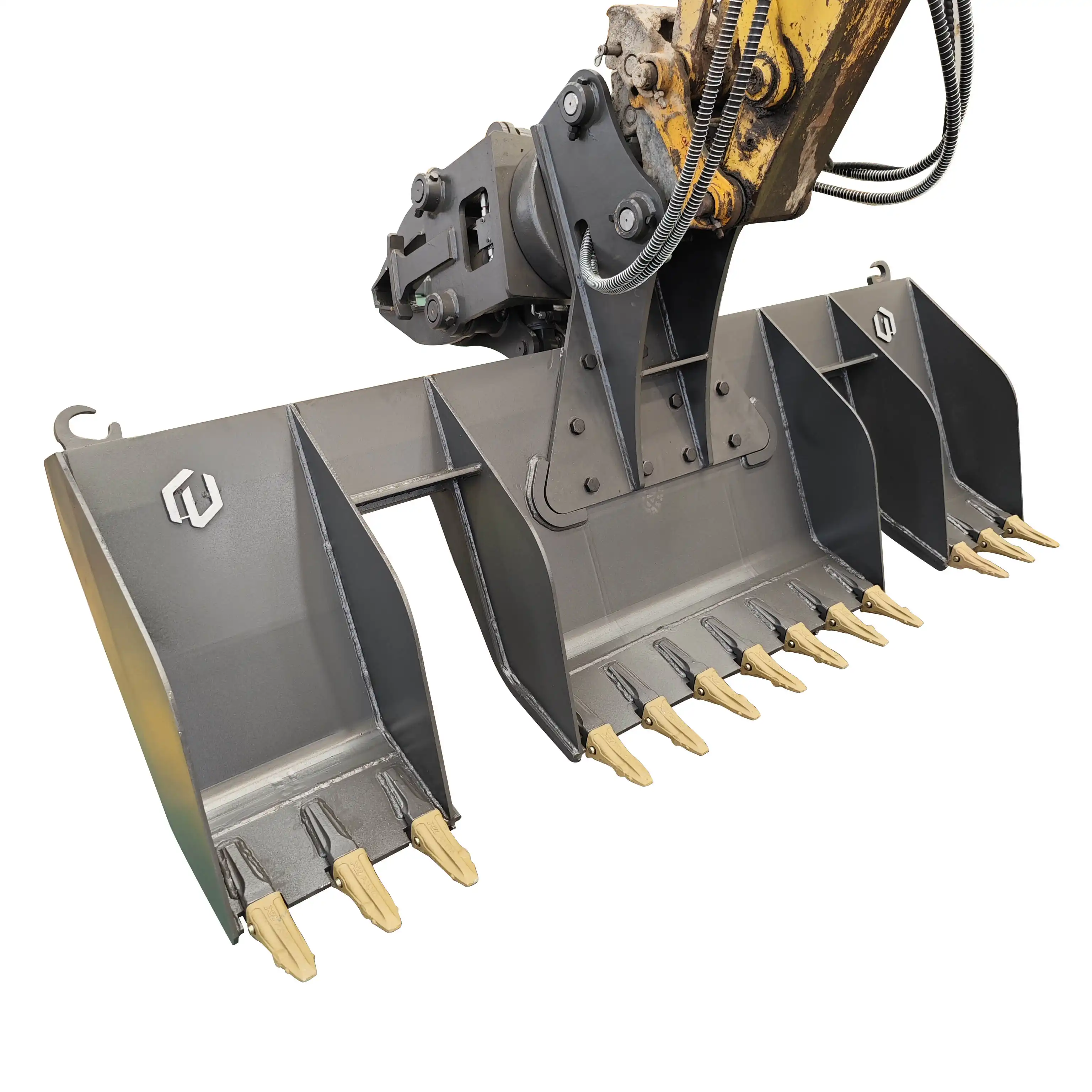

3. Evaluate Bucket Design Features

Different bucket designs offer various advantages. For example, a general-purpose bucket with a flat bottom is versatile for most applications, while a high-capacity bucket with a spill guard might be better suited for handling light materials. Consider features like wear plates, cutting edges, and teeth, which can enhance performance and durability.

4. Factor in the Work Environment

The conditions of your work site can influence the optimal bucket capacity. Confined spaces may require smaller buckets for better maneuverability, while open areas might allow for larger capacities to improve efficiency. Additionally, consider factors like ground conditions and the need for specialized attachments.

5. Balance Capacity with Cycle Times

While a larger bucket can move more material per load, it may also increase cycle times due to longer filling and dumping periods. Strike a balance between capacity and cycle times to optimize overall productivity. In some cases, a slightly smaller bucket with faster cycle times might outperform a larger one.

6. Consult with Experts

When in doubt, consult with equipment dealers, manufacturers, or experienced operators. Their insights can be invaluable in selecting the right bucket capacity for your specific needs. Many manufacturers offer sizing charts and calculators to help match buckets to loaders and applications.

How Does Bucket Capacity Vary Across Different Industries?

Front loader bucket capacities can vary significantly across industries due to the diverse nature of materials handled and specific operational requirements. Let's explore how bucket capacities typically differ in various sectors:

1. Construction Industry

In construction, bucket capacities can range widely depending on the specific application. For general earthmoving and site preparation, medium to large-capacity buckets (2-4 cubic yards) are common. However, for more precise work like grading or working in confined spaces, smaller buckets (1-2 cubic yards) may be preferred. Specialized buckets, such as rock buckets for handling large aggregate or multi-purpose buckets for versatility, are also frequently used in construction.

2. Mining and Quarrying

The mining and quarrying industries often require larger bucket capacities to handle heavy, dense materials efficiently. Bucket capacities in these sectors can range from 4 to 20 cubic yards or more, depending on the size of the operation and the type of material being extracted. Rock buckets with reinforced designs are common to withstand the abrasive nature of mining operations.

3. Agriculture

Agricultural applications typically use a range of bucket capacities depending on the task. For handling light materials like grain or silage, high-capacity buckets (3-5 cubic yards) are often used. However, for tasks like manure handling or soil moving, medium-capacity buckets (2-3 cubic yards) are more common. Multi-purpose buckets are popular in agriculture due to their versatility in handling various materials.

4. Waste Management

In the waste management industry, large-capacity buckets are often preferred to handle high volumes of relatively light materials. Bucket capacities can range from 3 to 8 cubic yards or more, with specialized designs featuring high backs to prevent spillage and increase capacity. Light material buckets with larger volumes are common in recycling facilities and transfer stations.

5. Forestry

Forestry applications often require specialized buckets with smaller capacities (1-2 cubic yards) due to the need for maneuverability in wooded areas. Buckets used in this industry may feature reinforced designs to handle logs and debris, as well as grapple attachments for better control of materials.

6. Snow Removal

For snow removal operations, large-capacity, light-material buckets are typically used. These can range from 3 to 6 cubic yards or more, depending on the size of the loader and the scale of the snow removal operation. Snow buckets often feature a high back and may include a snow push attachment for increased efficiency.

Front Loader Bucket for Sale

Choosing the right front loader bucket is crucial for maximizing productivity and efficiency in your operations. Tiannuo Machinery is a leading manufacturer and supplier of high-quality buckets, with over 10 years of experience in the industry. Specializing in OEM services, we offer fast delivery, strict packaging standards, and support customization to meet the diverse needs of our clients. If you are choosing your front loader bucket manufacturer, we invite you to experience the Tiannuo difference.

For personalized assistance and to discuss your specific bucket requirements, please don't hesitate to contact our team:

- Manager: arm@stnd-machinery.com

- Team Member: rich@stnd-machinery.com

- Team Member: tn@stnd-machinery.com

Let Tiannuo Machinery help you find the perfect front loader bucket solution for your needs.

References

- Caterpillar Inc. (2021). "Bucket Selection Guide."

- Volvo Construction Equipment. (2020). "Material Density and Bucket Selection."

- John Deere. (2022). "Loader Bucket Capacity and Performance Guide."

- Komatsu. (2021). "Bucket Materials and Construction."

- Case Construction Equipment. (2022). "Application-Specific Bucket Selection."

- Liebherr Group. (2021). "Wheel Loader Bucket Selection Guide."