Telescopic or Fixed: Which Form of Excavator Lift Cab is Right for You?

When it comes to enhancing the operational efficiency and versatility of excavators, the choice between telescopic and fixed lift cabs plays a crucial role. An excavator lift cab is a specialized component designed to elevate the operator's position, providing improved visibility and access to challenging work environments. In this comprehensive guide, we'll explore the key differences between telescopic and fixed excavator lift cabs, helping you determine which option best suits your operational needs.

Understanding Excavator Lift Cabs: Telescopic vs. Fixed

Excavator lift cabs are innovative additions to heavy machinery that significantly enhance an operator's ability to perform tasks in various settings. These cabs come in two primary forms: telescopic and fixed. Each type offers distinct advantages and considerations, making it essential to understand their characteristics before making a decision.

Telescopic lift cabs, as the name suggests, feature an extendable mechanism that allows the cab to be raised to different heights. This flexibility enables operators to adjust their vantage point based on the specific requirements of the task at hand. On the other hand, fixed lift cabs are set at a predetermined elevation, offering a consistent raised position throughout operation.

The choice between telescopic and fixed lift cabs often depends on the nature of the work, the terrain, and the specific challenges faced in different job sites. Both options aim to improve visibility and operational efficiency, but they achieve these goals through different means.

Key Differences Between Telescopic and Fixed Excavator Lift Cabs

To make an informed decision about which type of excavator lift cab is right for your needs, it's crucial to understand the key differences between telescopic and fixed options:

1. Adjustability: Telescopic lift cabs offer the advantage of height adjustability. Operators can raise or lower the cab to achieve optimal visibility for different tasks or to navigate obstacles. Fixed lift cabs, while elevated, maintain a constant height throughout operation.

2. Complexity: Telescopic systems typically involve more complex mechanisms to enable the extension and retraction of the cab. This complexity can lead to higher maintenance requirements and potential repair costs. Fixed lift cabs, with their simpler design, often require less maintenance and have fewer moving parts to manage.

3. Stability: Fixed lift cabs generally provide enhanced stability due to their rigid structure. Telescopic cabs, while engineered for safety, may experience slight movement or vibration when fully extended, particularly in challenging conditions.

4. Initial Cost: The advanced technology and additional components required for telescopic lift cabs often result in a higher initial investment compared to fixed alternatives. However, the versatility offered by telescopic options may offset this cost difference in certain applications.

5. Versatility: Telescopic lift cabs excel in versatility, allowing operators to adapt to various working heights and conditions. Fixed lift cabs, while less adaptable, provide a consistent elevated position that may be ideal for specific, repetitive tasks.

6. Transport and Storage: When it comes to transportation and storage, fixed lift cabs generally have an advantage. Their constant profile makes them easier to transport on low-bed trailers and store in height-restricted areas. Telescopic cabs may require additional considerations for transport and storage when fully extended.

Which Excavator Lift Cab Type Suits Your Operational Needs: Telescopic vs. Fixed?

Choosing between telescopic and fixed excavator lift cabs depends on a thorough assessment of your operational requirements. Consider the following factors to determine which option aligns best with your needs:

1. Work Environment Variability: If your projects frequently involve diverse terrains and varying height requirements, a telescopic lift cab offers the flexibility to adapt to different scenarios. For operations that primarily occur in consistent environments with standard height needs, a fixed lift cab may be more suitable.

2. Frequency of Height Adjustments: Evaluate how often you need to change the operator's viewing height during typical operations. If frequent adjustments are necessary, the convenience of a telescopic system could significantly enhance productivity. For tasks that rarely require height changes, a fixed cab might be more cost-effective.

3. Budget Considerations: While initial cost shouldn't be the sole determining factor, it's important to consider your budget constraints. Telescopic lift cabs generally come with a higher price tag due to their advanced features. However, the potential productivity gains may justify the investment for certain applications.

4. Maintenance Resources: Consider your ability to maintain and service more complex equipment. Telescopic lift cabs may require specialized maintenance and more frequent inspections to ensure proper functioning of the extension mechanism. If you have limited maintenance resources, a fixed lift cab might be a more practical choice.

5. Operator Preferences: Consult with your operators to understand their preferences and experiences. Some operators may feel more comfortable with the stability of a fixed cab, while others may appreciate the adaptability of a telescopic system.

6. Safety Regulations: Review local safety regulations and industry standards that may impact the use of elevated cabs. Ensure that the chosen lift cab type complies with all relevant safety requirements for your specific applications.

7. Long-term Versatility: Consider the potential for future projects and how they might benefit from either a fixed or telescopic lift cab. Opting for a more versatile solution could provide long-term advantages as your operations evolve.

Advantages of Telescopic Lift Cabs in Reaching Difficult Locations

Telescopic lift cabs offer several distinct advantages when it comes to accessing challenging work areas:

1. Enhanced Visibility: The ability to adjust the excavator lift cab's height allows operators to gain a clear view of hard-to-see areas, such as the bottom of deep excavations or the tops of tall structures. This improved visibility contributes to more precise and efficient operations.

2. Adaptability to Varying Terrain: In projects with uneven or sloped terrain, telescopic lift cabs enable operators to maintain an optimal viewing angle regardless of the ground conditions. This adaptability is particularly valuable in construction sites with complex topography.

3. Improved Safety in Hazardous Environments: When working in potentially dangerous areas, such as near unstable slopes or in demolition zones, telescopic lift cabs allow operators to position themselves at a safe distance while maintaining visual control over the work area.

4. Efficient Material Handling: For tasks involving the loading and unloading of materials at various heights, telescopic lift cabs provide the flexibility to align the operator's line of sight with the task at hand, reducing the risk of errors and improving overall efficiency.

5. Versatility in Multi-level Projects: In multi-story construction or demolition projects, telescopic lift cabs enable operators to adjust their position to work effectively at different levels without the need to reposition the entire machine.

6. Enhanced Precision in Restricted Spaces: When working in confined areas with overhead obstacles, the ability to fine-tune the cab's height allows for precise maneuvering and operation, minimizing the risk of collisions or damage to surrounding structures.

7. Improved Operator Comfort: By allowing operators to adjust their position for optimal visibility, telescopic lift cabs can reduce strain and fatigue associated with maintaining awkward postures for extended periods.

While telescopic lift cabs offer these advantages in reaching difficult locations, it's important to note that fixed lift cabs can still provide significant benefits in terms of stability and simplicity for certain applications. The choice between the two ultimately depends on the specific demands of your projects and operational priorities.

China Excavator Lift Cab

In conclusion, the choice between telescopic and fixed excavator lift cabs depends on a careful evaluation of your operational needs, budget constraints, and long-term goals. Both options offer unique advantages, and the right choice can significantly enhance your excavator's versatility and efficiency.

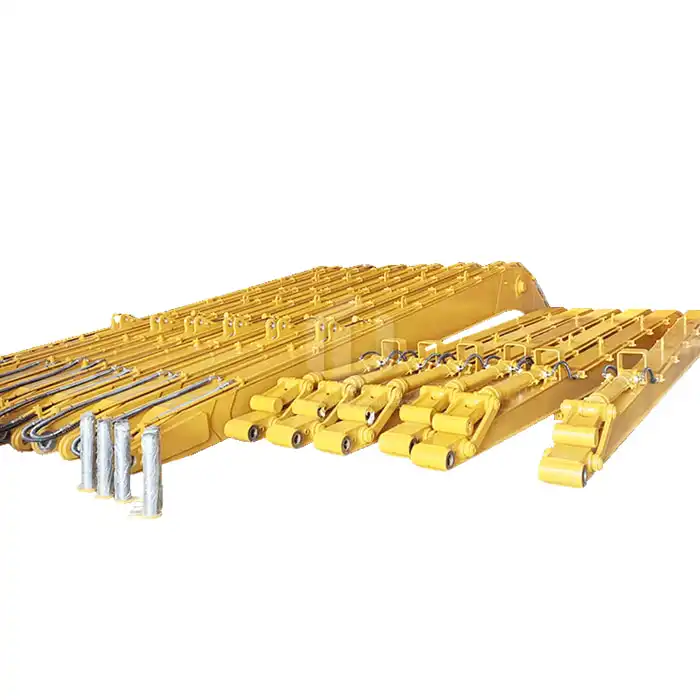

Applicable to models ranging from 13 to 50 tons, this lift cab offers a standard lifting height of 2500 mm, which can be tailored to meet specific requirements. Once lifted, the cab stands at an impressive 3800 mm above the ground, providing an elevated vantage point for the operator. The cab can be moved forward by 800 mm, significantly improving the driver's field of vision, which extends up to 5000-5300 mm. The driver's lifting speed is adjustable, ensuring comfort and precision during operation. The lift cab is available in both telescopic and fixed forms, offering flexibility based on operational needs. For added safety, an emergency system allows for one-click descent in case of unexpected situations.

If you are choosing your excavator lift cab manufacturer, please feel free to reach out to Tiannuo Machinery's manager at arm@stnd-machinery.com and the team at rich@stnd-machinery.com and tn@stnd-machinery.com. Our team of experts is ready to assist you in selecting the perfect excavator lift cab solution for your specific needs, ensuring optimal performance and safety in your operations.

References:

[1] Construction Equipment. (2021). "Lift Cab Systems for Excavators: Enhancing Visibility and Safety."

[2] Journal of Construction Engineering. (2020). "Comparative Analysis of Telescopic and Fixed Lift Cabs in Heavy Machinery."

[3] International Journal of Industrial Ergonomics. (2019). "Operator Comfort and Efficiency in Elevated Cab Excavators."

[4] Safety Science. (2022). "Risk Assessment and Mitigation Strategies for Elevated Excavator Operations."