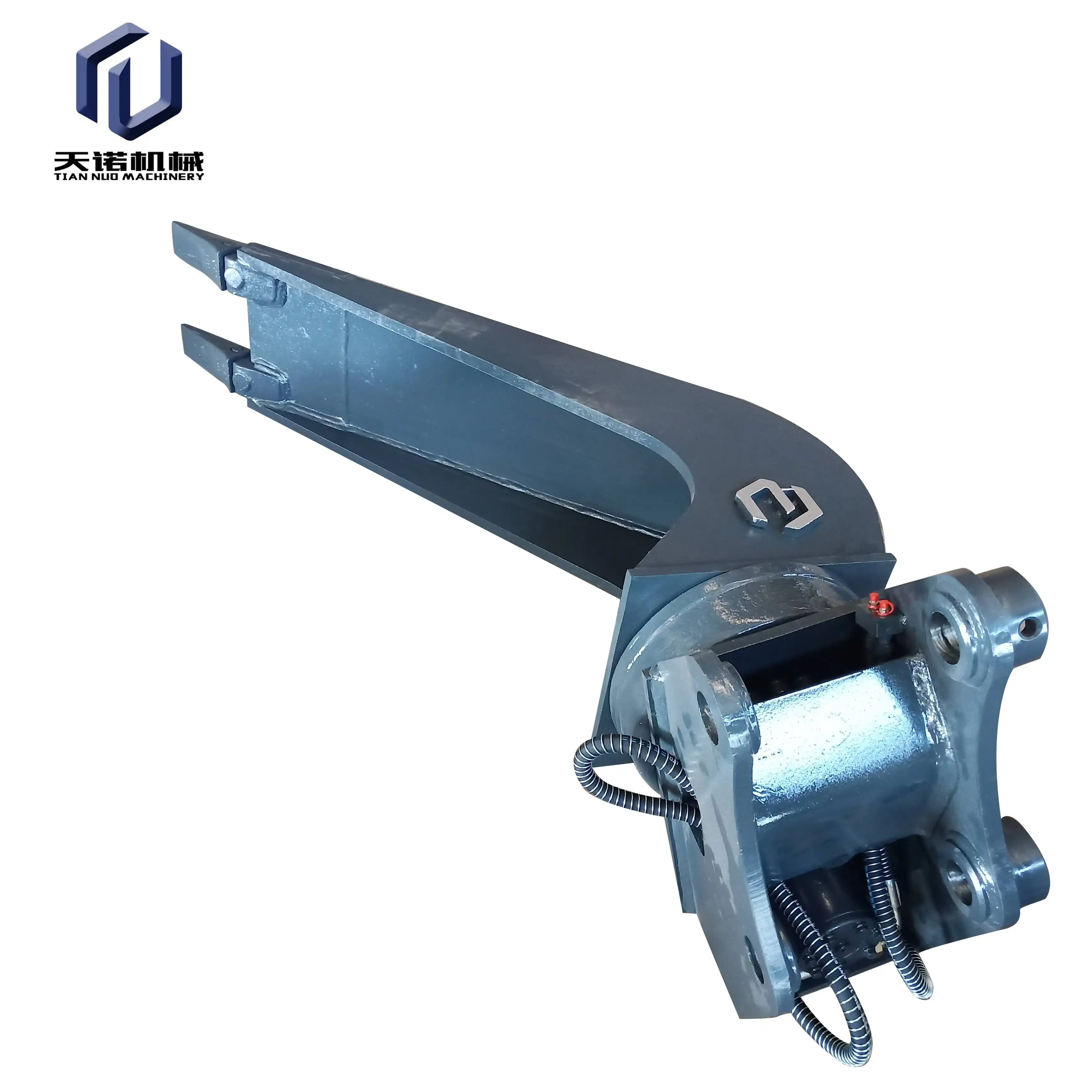

Railway Excavator Ballast Plow For Sale

Are you searching for a reliable and efficient railway excavator ballast plow to optimize your track maintenance operations? At Tiannuo Machinery, we offer premium quality ballast plows designed specifically for railway applications. Our excavator ballast plow attachments are engineered to provide superior performance in ballast distribution, track profiling, and shoulder cleaning operations. With over a decade of experience manufacturing excavator attachments, we've developed ballast plows that combine durability, precision, and cost-effectiveness to meet the demanding requirements of modern railway maintenance.

The ballast plow is an essential piece of equipment for any railway maintenance company seeking to improve operational efficiency while reducing maintenance costs. These specialized attachments transform standard excavators into versatile railway maintenance machines capable of precisely redistributing ballast material, clearing drainage channels, and maintaining proper track geometry. Our ballast plows are compatible with various excavator models, including Komatsu, Hitachi, and Caterpillar, allowing you to maximize the utility of your existing equipment fleet.

Railway infrastructure requires regular maintenance to ensure safe and efficient operations. Ballast, the crushed stone that forms the bed of railway tracks, tends to shift over time due to train vibrations, weather conditions, and natural settling. Proper ballast distribution is crucial for maintaining track stability, drainage, and longevity. Our excavator ballast plow solutions offer a cost-effective approach to ballast management, enabling maintenance crews to quickly restore optimal ballast profiles without the need for specialized rail vehicles or extensive manual labor.

Why Choose a Railway Excavator Ballast Plow for Track Maintenance?

Enhanced Track Stability and Safety

Railway track stability directly impacts operational safety and service reliability. Properly distributed ballast provides essential support to railway sleepers and rails, preventing unwanted movement and maintaining correct track geometry. A railway excavator ballast plow offers precise control over ballast distribution, allowing maintenance teams to create optimal track profiles that enhance stability.

The ballast bed must maintain specific dimensions and density to effectively support the railway structure. Over time, ballast can become unevenly distributed, creating areas with insufficient support that may lead to track misalignment, excessive vibration, or even derailment risks. By utilizing our excavator-mounted ballast plows, maintenance crews can quickly identify and correct these irregularities, ensuring consistent support throughout the track system.

Additionally, proper ballast distribution plays a crucial role in managing thermal expansion and contraction of rails. When ballast is correctly positioned, it helps secure the track against lateral movement that might otherwise occur during temperature fluctuations. This is particularly important in regions experiencing extreme temperature variations, where track buckling presents a serious safety concern.

Improved Drainage Capabilities

Effective drainage is essential for maintaining railway infrastructure integrity. Standing water accelerates ballast degradation, promotes vegetation growth, and can undermine the structural foundation of the track. Our railway excavator ballast plow attachments are designed with specific features that enhance drainage profiles along the track.

The adjustable blades of our ballast plows can create the precise slopes needed to direct water away from the track structure. By maintaining proper ballast shoulders and cleaning drainage ditches alongside the tracks, our equipment helps prevent water accumulation that could compromise track stability. This proactive approach to water management extends the service life of both the ballast material and the underlying subgrade.

Moreover, improved drainage reduces the frequency of maintenance interventions required, translating to lower operational costs and reduced service disruptions. Railway operators who invest in proper drainage maintenance using quality ballast plows typically experience fewer emergency repairs and extended maintenance cycles.

Cost-Effective Maintenance Solution

Traditional railway maintenance often requires specialized machines that run on the tracks themselves. These dedicated machines, while effective, represent significant capital investments and may cause extended service interruptions during deployment. A railway excavator ballast plow offers a more flexible and economical alternative for many maintenance tasks.

By converting standard excavators into specialized railway maintenance equipment, companies can leverage their existing machinery fleet more effectively. This multi-purpose approach eliminates the need for multiple specialized machines, reducing capital expenditure and storage requirements. The versatility of excavator-mounted attachments allows maintenance teams to perform various tasks with a single base machine simply by changing attachments.

Furthermore, excavators can access areas that track-bound maintenance vehicles cannot reach, providing greater operational flexibility. This accessibility is particularly valuable when addressing localized issues or working in remote sections of track with limited access points. Our ballast plows are designed for quick attachment and detachment, minimizing setup time and maximizing productive work hours.

How Efficient Is the Railway Excavator Ballast Plow in Ballast Distribution?

Precision Ballast Profiling Capabilities

The efficiency of a railway excavator ballast plow is measured primarily by its ability to create precise ballast profiles that meet engineering specifications. Our ballast plows feature adjustable blades and wings that can be configured to match specific track profile requirements. This adaptability enables maintenance crews to achieve consistent results across different track sections and ballast conditions.

The hydraulic controls of modern excavators provide operators with exceptional precision when manipulating the ballast plow. This level of control allows for fine adjustments to ballast distribution, ensuring that material is placed exactly where needed without wastage. The ability to make real-time adjustments based on visual inspection results in higher quality outcomes compared to less precise methods.

Our ballast plows incorporate design features that prevent over-excavation or disturbance of the track structure during operation. Safety limiters and guide systems help operators maintain proper working depths and angles, protecting underlying components while maximizing redistribution efficiency. This precision not only improves the quality of maintenance work but also reduces the risk of accidental damage to track infrastructure.

Operational Speed and Productivity

Railway maintenance operations often face tight scheduling constraints due to the need to restore normal train services as quickly as possible. The railway excavator ballast plow significantly increases maintenance productivity by efficiently moving and redistributing large volumes of ballast material in a single pass. Our plows are designed with optimal blade shapes and sizes to maximize material movement while minimizing power requirements.

Compared to manual ballast regulation or smaller equipment, an excavator-mounted ballast plow can cover substantially more track distance per working shift. This increased coverage translates directly to shorter maintenance windows and reduced service disruptions. For railway operators, this efficiency means more operational uptime and improved service reliability.

Additionally, our ballast plows are engineered to maintain consistent performance even when working with varied ballast materials or conditions. Whether dealing with fresh ballast placement or redistributing existing material, the equipment delivers reliable results with minimal adjustment requirements. This consistency helps maintenance planners establish accurate timelines and resource allocations for track work projects.

Versatility Across Different Track Sections

Railway networks comprise various track configurations, including mainlines, sidings, switches, and level crossings. Each section presents unique maintenance challenges that require adaptable equipment. Our railway excavator ballast plow attachments are designed with this versatility in mind, featuring adjustable components that can be configured for different working conditions.

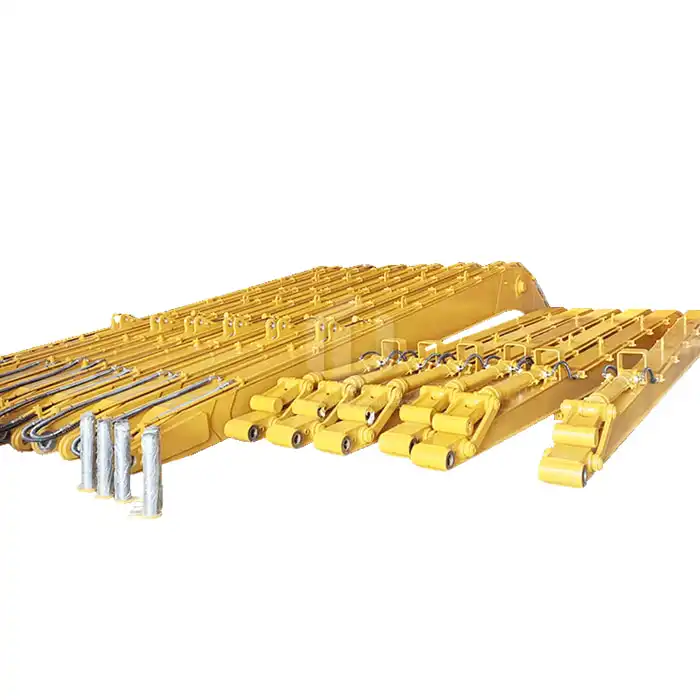

The modular design of our ballast plows allows for customization based on specific maintenance requirements. Wings and blades can be adjusted to accommodate different track widths, ballast shoulder profiles, and working depths. This adaptability enables maintenance teams to maintain consistent quality standards across the entire railway network without requiring multiple specialized tools.

For areas with restricted clearance or special infrastructure considerations, our compact ballast plow models provide the necessary flexibility without compromising on functionality. The excavator's reach capabilities also allow operators to access difficult areas from various positions, increasing the equipment's utility in complex track environments such as bridges, tunnels, or areas with adjacent structures.

What Are the Advantages of Using an Excavator-Mounted Ballast Plow?

Reduced Labor Requirements

Traditional ballast maintenance often involves significant manual labor, which is both costly and time-consuming. By implementing a railway excavator ballast plow solution, maintenance operations can be largely mechanized, dramatically reducing the personnel requirements for track maintenance activities. A single skilled operator with an excavator and ballast plow attachment can accomplish work that would otherwise require multiple laborers with hand tools.

This reduction in labor intensity not only decreases direct costs but also minimizes safety risks associated with manual track work. Railway environments present numerous hazards, including moving trains, heavy materials, and often challenging weather conditions. Mechanized maintenance using excavator attachments creates a safer working environment by removing workers from direct exposure to many of these hazards.

Additionally, the consistency of machine-performed work typically exceeds what can be achieved through manual methods. Human fatigue is eliminated as a factor in work quality, resulting in more uniform ballast profiles and better adherence to engineering specifications. This improved consistency translates to longer-lasting maintenance outcomes and reduced rework requirements.

Improved Maintenance Scheduling Flexibility

Railway operators must carefully balance maintenance needs against service requirements, often working within narrow time windows to minimize disruption. The mobility and efficiency of excavator-mounted railway excavator ballast plow systems provide significant advantages in maintenance scheduling flexibility. Unlike track-bound maintenance vehicles that require specific access points, excavators can be transported to work sites via road and deployed quickly.

This mobility enables maintenance teams to respond more effectively to emerging issues or take advantage of unplanned service gaps. When weather events or other factors create ballast displacement requiring immediate attention, excavator-based systems can be rapidly deployed to address these localized issues without extensive planning or specialized transport arrangements.

Furthermore, the independent operation of excavator-based maintenance systems allows for more parallel work activities during maintenance windows. While specialized track machines often require exclusive access to track sections, excavators can work alongside other maintenance activities in many cases, maximizing the productive use of limited access time. This coordination flexibility helps railway operators maintain infrastructure quality while minimizing service impacts.

FAQ

1. What excavator sizes are compatible with your ballast plows?

Our railway excavator ballast plow attachments are designed to fit excavators ranging from 14 to 45 tons, with different models optimized for specific weight classes. We provide detailed compatibility information during the consultation process to ensure you select the appropriate model for your existing equipment.

2. How quickly can operators learn to use the ballast plow effectively?

Most experienced excavator operators can become proficient with the railway excavator ballast plow after a single training session and 1-2 days of supervised operation. We provide comprehensive operator training and reference materials with each purchase.

3 . What maintenance does the ballast plow require?

Our ballast plows are engineered for durability in demanding railway environments. Regular maintenance includes greasing pivot points, inspecting wear components, and periodic blade replacement. A detailed maintenance schedule is provided with each unit.

4 .Can the ballast plow work in confined spaces?

Yes, our compact railway excavator ballast plow models are specifically designed for operation in tunnels, bridges, and other areas with restricted clearance while maintaining essential functionality.

At Tiannuo Machinery, we specialize in manufacturing high-quality excavator attachments, including our premium railway excavator ballast plow line. With over 10 years of experience serving the railway construction and maintenance industry, we understand the unique challenges faced by infrastructure maintenance providers. Our ballast plows are designed and built to exacting standards, ensuring reliability and performance in demanding railway environments.

If you're looking to enhance your track maintenance capabilities with a durable, efficient railway excavator ballast plow, contact our technical team for a personalized consultation. We can help you select the optimal model for your specific application requirements and equipment fleet. For more information or to request a quote, please contact us at arm@stnd-machinery.com, rich@stnd-machinery.com, and tn@stnd-machinery.com.

References

- Railway Track Maintenance Handbook: Best Practices in Ballast Management (2023)

- Modern Approaches to Railway Infrastructure Maintenance (2022)

- Excavator Attachments in Railway Construction and Maintenance (2021)

- Ballast Regulation Techniques for Enhanced Track Stability (2023)

- Cost-Benefit Analysis of Mechanized Railway Maintenance Systems (2022)

About Author: Arm

Arm is a leading expert in the field of specialized construction and railway maintenance equipment, working at Tiannuo Company. Tiannuo specializes in manufacturing a wide range of products, including railway maintenance equipment like railway sleeper changing machines and screening machines, excavator modification equipment such as excavator lifting cabs, various engineering arms for excavators, excavator accessories like digging buckets, and engineering vehicle auxiliary equipment like loader buckets.