How long is a standard excavator boom?

Excavators are versatile machines that play a crucial role in various construction and earthmoving projects. One of the most important components of an excavator is its boom, which determines the machine's reach and digging capability. In this comprehensive guide, we'll explore the standard size excavator boom and arm, discussing their typical dimensions, variations across different models, and the importance of boom length for operational efficiency.

What are the typical dimensions of a standard excavator boom?

The dimensions of a standard excavator boom can vary significantly depending on the size and class of the machine. Generally, excavators are categorized into mini, compact, mid-size, and large excavators, each with its own typical boom lengths.

For mini excavators (weighing 0.7 to 8.5 tons), the boom length typically ranges from 1.5 to 3.5 meters (5 to 11.5 feet). These smaller machines are designed for work in confined spaces and light-duty applications.

Compact excavators (weighing 8.5 to 12 tons) usually have boom lengths between 3.5 to 4.5 meters (11.5 to 15 feet). These versatile machines strike a balance between maneuverability and digging power.

Mid-size excavators (weighing 12 to 45 tons) come with boom lengths ranging from 4.5 to 7 meters (15 to 23 feet). These machines are commonly used in general construction and earthmoving projects.

Large excavators (weighing over 45 tons) can have boom lengths exceeding 7 meters (23 feet), with some specialized models reaching up to 15 meters (49 feet) or more. These massive machines are designed for heavy-duty applications such as mining and large-scale excavation projects.

It's important to note that these dimensions are general guidelines, and specific models may deviate from these ranges. Manufacturers often offer various boom options for each excavator model to cater to different job requirements.

How does the boom length vary across different excavator models?

The variation in boom length across different excavator models is significant and is influenced by several factors:

1. Machine Size: As mentioned earlier, larger excavators generally have longer booms. This correlation is due to the increased power and stability of larger machines, which can support and control longer booms effectively.

2. Application Requirements: Manufacturers design different boom lengths to suit various applications. For instance, excavators used in trenching might have longer booms for increased reach, while those used in heavy lifting might have shorter, more robust booms.

3. Standard vs. Long Reach: Many manufacturers offer both standard and long-reach versions of their excavator models. Long-reach variants typically have boom lengths 20-40% greater than their standard counterparts, allowing for extended digging depths and reach.

4. Customization: Some manufacturers offer customizable excavator boom options, allowing customers to specify the exact length needed for their specific applications.

5. Attachments: The use of different attachments can also affect the effective reach of an excavator. For example, using a longer arm or a stick extension can increase the overall reach without changing the boom itself.

These examples demonstrate how boom lengths can vary not only between different size classes but also within the same class of excavators.

Why is the length of an excavator boom important for operational efficiency?

The length of an excavator boom plays a crucial role in determining the machine's operational efficiency. Here are several reasons why boom length is so important:

1. Reach and Digging Depth: A longer boom allows for greater horizontal reach and vertical digging depth. This extended reach can significantly reduce the need to reposition the excavator, saving time and increasing productivity, especially in applications like trenching or excavating large areas.

2. Versatility: The right boom length can make an excavator more versatile, allowing it to perform a wider range of tasks. For example, a longer boom might enable an excavator to reach across obstacles or work at a safe distance from unstable ground.

3. Lifting Capacity: While longer booms provide greater reach, they typically reduce the maximum lifting capacity of the excavator. This is because the leverage effect increases with boom length, requiring more counterweight to maintain stability. Operators must balance reach requirements with lifting needs to optimize efficiency.

4. Maneuverability: In confined spaces, a shorter boom can provide better maneuverability. This is particularly important in urban construction sites or when working inside buildings.

5. Fuel Efficiency: The length of the boom affects the overall weight distribution and center of gravity of the excavator. A well-matched boom length can contribute to better fuel efficiency by reducing unnecessary strain on the machine.

6. Safety: The right boom length can enhance safety on the job site. For instance, a longer boom allows operators to maintain a safe distance from hazardous areas or unstable ground while still reaching the work area.

7. Transportation: Boom length affects the ease of transporting the excavator between job sites. Longer booms may require special transportation arrangements, which can impact overall project logistics and costs.

8. Precision: In some applications, such as grading or finishing work, a shorter boom can provide better control and precision, as it reduces the effect of small movements at the base of the boom.

9. Cycle Times: The boom length directly influences the excavator's cycle times. A well-matched boom length for the specific task can optimize cycle times, increasing overall productivity.

10. Adaptability: Some modern excavators offer adjustable boom configurations, allowing operators to adapt the machine's reach and performance characteristics to different job requirements without changing machines.

Given these factors, selecting the appropriate boom length is crucial for maximizing an excavator's efficiency and productivity. Construction managers and equipment operators must carefully consider the specific requirements of their projects when choosing an excavator with the optimal boom length [5].

Standard Size Excavator Boom And Arm

Understanding the standard size excavator boom and arm is crucial for optimizing construction and earthmoving operations. The length of an excavator's boom significantly impacts its reach, digging depth, and overall performance. While standard dimensions vary across different machine sizes and models, choosing the right boom length for your specific application can greatly enhance operational efficiency, safety, and productivity.

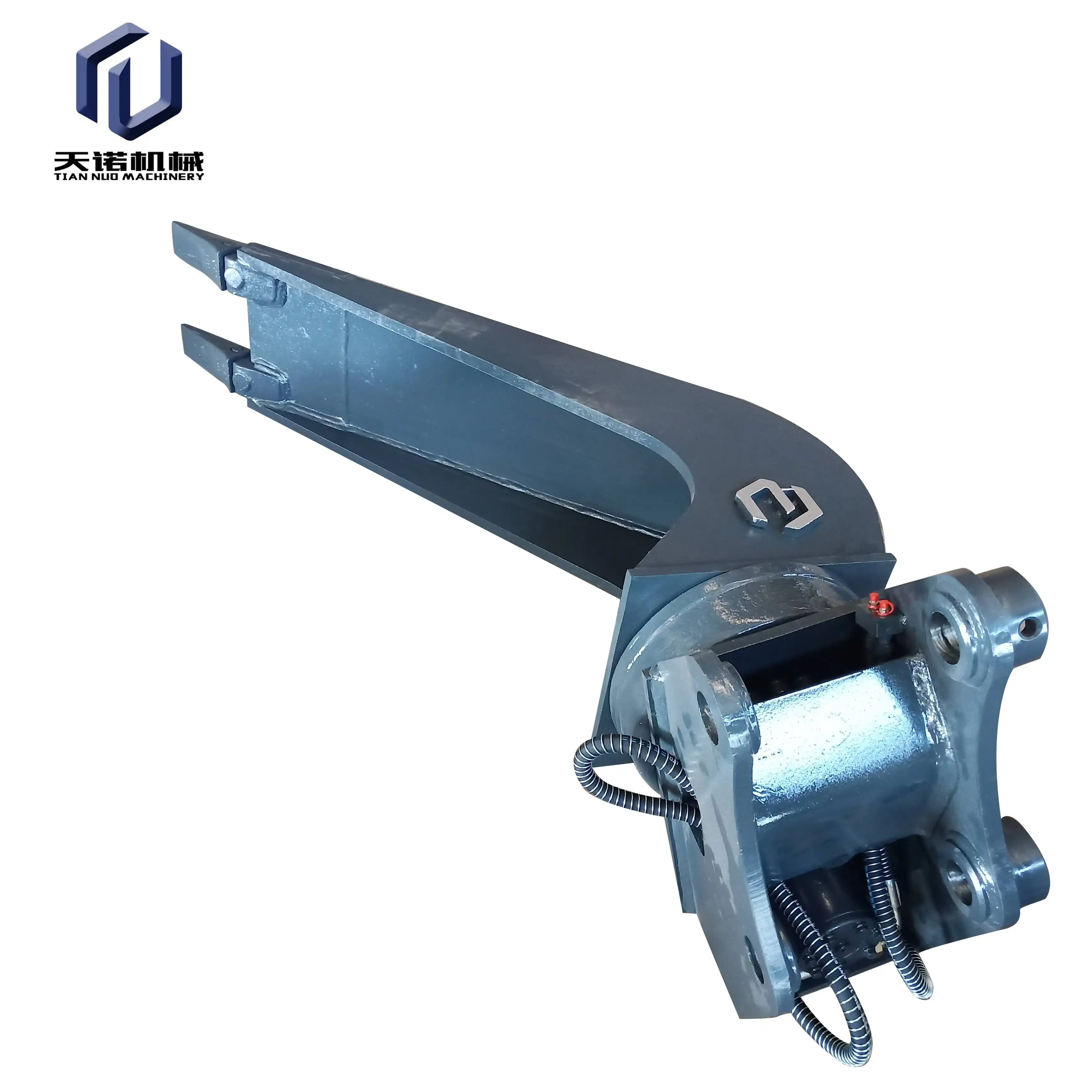

Tiannuo Machinery stands at the forefront of excavator multifunctional equipment manufacturing. Our flagship product, the standard size excavator boom and arm, is crafted from high-strength steel, offering unparalleled durability and performance. With a maximum reach of up to 15 meters and an impressive lifting capacity of up to 30 tons, our boom and arm system is designed to meet the most demanding job site requirements.

Compatible with all major excavator brands, our product ensures versatility across various equipment fleets. We understand that every project is unique, which is why we also offer customization services to tailor our products to your specific needs. Safety is our top priority, and our boom and arm system features advanced overload protection and reinforced stability to ensure secure operations in all conditions.

For more information or to discuss how our standard size excavator boom and arm can enhance your operations, please don't hesitate to reach out. Contact our manager at arm@stnd-machinery.com, or our team members at rich@stnd-machinery.com and tn@stnd-machinery.com. Let Tiannuo Machinery be your partner in achieving new heights of efficiency and productivity in your excavation projects.

References:

[1] Caterpillar. (2021). Excavator Size Classes Explained. Caterpillar.

[2] Caterpillar. (2022). 320 GC Hydraulic Excavator Specifications. Caterpillar.

[3] Komatsu. (2022). PC210LC-11 Hydraulic Excavator. Komatsu.

[4] Bobcat. (2022). E35 and E50 Compact Excavator Specifications. Bobcat.

[5] Construction Equipment. (2020). Choosing the Right Excavator Boom and Arm. Construction Equipment Magazine.

YOU MAY LIKE

VIEW MOREExcavator Hydraulic Rail Clamp

VIEW MOREExcavator Hydraulic Rail Clamp VIEW MOREExcavator ballast cleaning hopper

VIEW MOREExcavator ballast cleaning hopper VIEW MOREExcavator lift cab modification

VIEW MOREExcavator lift cab modification VIEW MOREExcavator Tree Stumper

VIEW MOREExcavator Tree Stumper VIEW MOREExcavator Special-Shaped Bucket

VIEW MOREExcavator Special-Shaped Bucket VIEW MOREExcavator High Reach Demolition Long Boom And Arm

VIEW MOREExcavator High Reach Demolition Long Boom And Arm VIEW MOREExcavator Piling Boom

VIEW MOREExcavator Piling Boom VIEW MOREUnloading Train Excavator Long Legs

VIEW MOREUnloading Train Excavator Long Legs