How does the 360° rotation angle enhance the performance of the railway excavator ballast plow?

Railway maintenance is a critical aspect of ensuring safe and efficient train operations. One of the key tools in this process is the railway excavator ballast plow, a versatile attachment designed to clear and shape ballast along railway tracks. In recent years, the introduction of 360° rotation functionality has revolutionized the performance of these essential machines. This article explores how this innovative feature enhances the capabilities of ballast plows, improving efficiency, adaptability, and overall performance in railway maintenance operations.

How does 360° rotation improve ballast redistribution?

The 360° rotation angle of modern railway excavator ballast plows offers a significant improvement in ballast redistribution capabilities. This enhanced maneuverability allows operators to precisely control the direction and angle of the plow, ensuring optimal ballast placement and shaping along the track.

One of the primary advantages of the 360° rotation is the ability to work on both sides of the track without repositioning the excavator. This feature dramatically reduces the time and effort required to maintain ballast profiles on opposite sides of the rail, leading to increased productivity and reduced operational costs. Operators can swiftly switch between tasks, such as clearing excess ballast from one side of the track and redistributing it to areas that require additional material on the other side, all without moving the base machine.

Furthermore, the rotational capability enables operators to tackle challenging areas that were previously difficult to access. For instance, when working on curved sections of track or in tight spaces between multiple tracks, the 360° rotation allows the plow to be positioned at the ideal angle for effective ballast manipulation. This precision ensures that the ballast is evenly distributed and properly compacted, contributing to improved track stability and longevity.

The enhanced control provided by the 360° rotation also allows for more delicate operations when working around sensitive track components. Operators can carefully maneuver the plow around obstacles such as signals, switches, and crossings, minimizing the risk of damage to these critical elements while still effectively managing the ballast.

Adapting to complex rail geometries using rotational functionality

Railway networks often feature complex geometries, including tight curves, steep gradients, and varying track widths. The 360° rotation angle of modern railway excavator ballast plows significantly enhances their ability to adapt to these challenging environments, ensuring effective maintenance across diverse rail layouts.

When working on curved sections of track, the rotational functionality allows operators to align the plow precisely with the curve's radius. This alignment ensures that the ballast is shaped and distributed evenly along the entire length of the curve, maintaining proper superelevation and reducing the risk of track misalignment. The ability to adjust the plow's angle on the fly also enables operators to compensate for changes in track curvature, ensuring consistent ballast profiles throughout transitions between straight and curved sections.

In areas with steep gradients, the 360° rotation proves invaluable for managing ballast distribution. Operators can adjust the plow's angle to account for the slope, preventing excess ballast from sliding down the grade and ensuring proper support for the track structure. This precise control is crucial for maintaining track integrity and preventing potential derailments in mountainous or hilly terrain.

The rotational capability also proves beneficial when working with varying track widths, such as those found in rail yards or at junction points. Operators can quickly adjust the plow's position and angle to accommodate different gauge widths, ensuring consistent ballast profiles across diverse track configurations. This adaptability is particularly useful in busy rail hubs where multiple track types may converge, streamlining maintenance operations and reducing the need for specialized equipment.

How does 360° rotation boost efficiency in narrow or confined rail areas?

Railway maintenance often involves working in narrow or confined spaces, such as tunnels, bridges, or urban environments with limited access. The 360° rotation angle of modern railway excavator ballast plows significantly enhances efficiency and effectiveness in these challenging scenarios.

In tunnel environments, where space is at a premium, the rotational functionality allows operators to position the plow optimally without the need to reposition the entire excavator. This capability is crucial for maintaining proper ballast profiles along the tunnel floor while avoiding contact with the tunnel walls or overhead structures. The precise control offered by the 360° rotation enables operators to work efficiently in these confined spaces, reducing the time required for maintenance tasks and minimizing disruptions to rail traffic.

When working on bridges or elevated track sections, the rotational feature proves invaluable for managing ballast at the edges of the structure. Operators can carefully control the plow's angle to prevent ballast from falling off the sides of the bridge while ensuring proper distribution and compaction. This precision is essential for maintaining track stability and preventing potential structural issues caused by uneven ballast loading.

In urban environments, where railway lines often run close to buildings or other infrastructure, the 360° rotation allows for more precise and controlled ballast management. Operators can adjust the plow's position to work effectively in tight spaces between tracks and adjacent structures, minimizing the risk of damage to surrounding property while ensuring proper track maintenance. This adaptability is particularly valuable in busy metropolitan areas where space is limited, and disruptions to rail service must be minimized.

The rotational functionality also enhances safety in confined work areas. By allowing operators to position the plow optimally without excessive maneuvering of the excavator, the risk of accidents or collisions with nearby obstacles is significantly reduced. This improved safety factor is crucial in environments where visibility may be limited or where multiple maintenance activities may be occurring simultaneously.

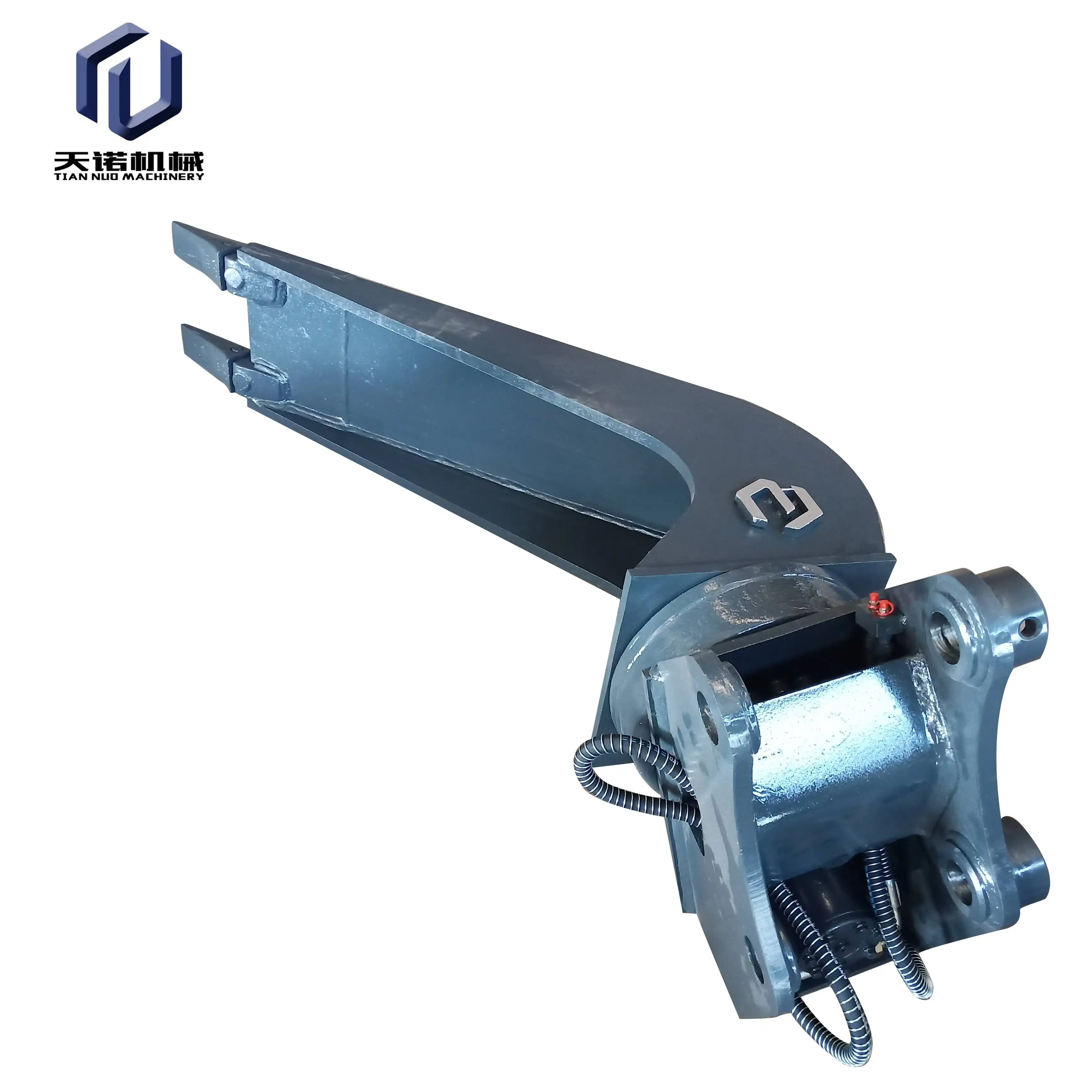

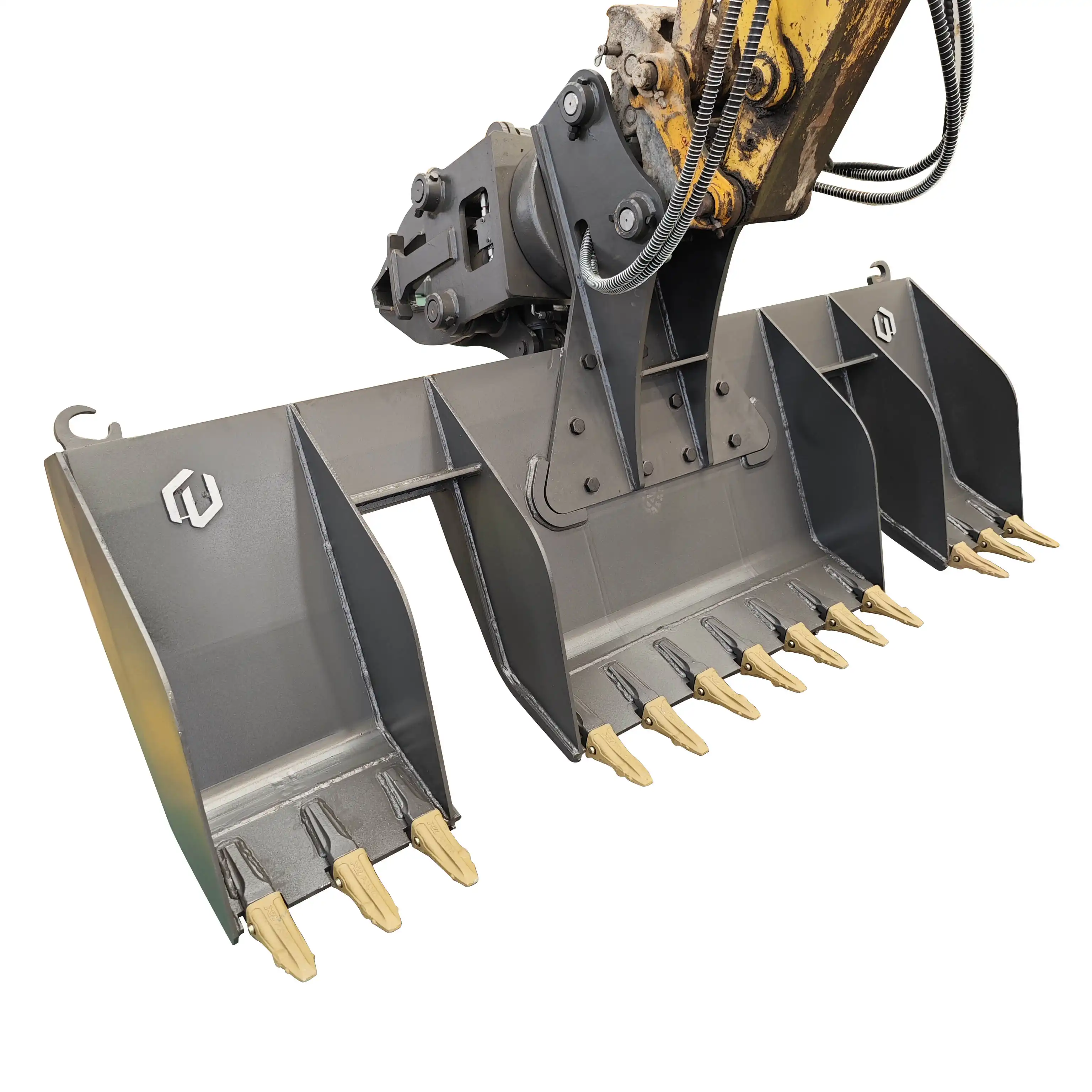

China Railway Excavator Ballast Plow

The 360° rotation angle has revolutionized the performance of railway excavator ballast plows, offering significant improvements in ballast redistribution, adaptability to complex rail geometries, and efficiency in narrow or confined areas. This innovative feature enhances the versatility and effectiveness of these essential maintenance tools, contributing to improved track stability, safety, and operational efficiency across diverse railway environments.

Railway excavator ballast plow is designed to work seamlessly with 7-15 ton excavators, making it an indispensable asset for railway maintenance and construction projects. Its primary function is to clear and shape ballast between the track and alongside the rails, ensuring optimal track conditions for safe and smooth train operations.

The plow boasts an impressive maximum width of 2814 mm and a maximum height of 1096 mm, allowing it to cover a large area with each pass. The working angle is fully adjustable, enabling operators to fine-tune the plow's performance to suit specific track conditions and requirements. With a full 360° rotation angle, the plow offers unparalleled maneuverability, making it easy to navigate around obstacles and work in tight spaces.

Constructed from high-strength alloy plate, this plow is built to withstand the rigors of heavy-duty use in harsh railway environments. Its robust design ensures long-lasting durability and reliability, minimizing downtime and maintenance costs. The hydraulic control operation mode provides precise and effortless control, allowing operators to focus on achieving optimal results. If you are choosing your railway excavator ballast plow manufacturer, please feel free to reach out to Tiannuo Machinery's manager at arm@stnd-machinery.com and the team at rich@stnd-machinery.com and tn@stnd-machinery.com.

References:

- Railway Track Maintenance and Renewal. (2018). International Union of Railways.

- Ballast Management Best Practices. (2019). American Railway Engineering and Maintenance-of-Way Association.

- Lichtberger, B. (2005). Track Compendium: Formation, Permanent Way, Maintenance, Economics. Eurailpress.

- Esveld, C. (2001). Modern Railway Track. MRT-Productions.

- Profillidis, V. A. (2006). Railway Management and Engineering. Ashgate Publishing, Ltd.

- Indraratna, B., Salim, W., & Rujikiatkamjorn, C. (2011). Advanced Rail Geotechnology - Ballasted Track. CRC Press.