Excavator Wood Splitter Maintenance

Excavator wood splitters are powerful tools that have revolutionized the forestry and lumber industries. These attachments, designed to work in tandem with excavators, provide an efficient means of splitting logs and processing timber. However, like any piece of heavy machinery, proper maintenance is crucial to ensure optimal performance, safety, and longevity.

Daily Maintenance Checklist for Your Wood Splitter

Maintaining your excavator wood splitter on a daily basis is fundamental to its performance and lifespan. A consistent routine not only prevents unexpected breakdowns but also helps identify potential issues before they escalate into costly repairs. Here's a detailed daily maintenance checklist to keep your wood splitter in top shape:

- Visual Inspection: Begin each day by conducting a thorough visual inspection of your excavator wood splitter. Look for any signs of wear, damage, or loose components. Pay particular attention to the cutting edge, hydraulic hoses, and mounting points.

- Check Fluid Levels: Ensure that all fluid levels, including hydraulic oil and engine oil (if applicable), are at the recommended levels. Low fluid levels can lead to poor performance and potential damage to internal components.

- Examine Cutting Edge: Inspect the cutting edge for any signs of dullness, chipping, or excessive wear. A sharp cutting edge is essential for efficient operation and clean cuts.

- Tighten Fasteners: Check and tighten all bolts, nuts, and other fasteners. Vibration during operation can cause these to loosen over time, potentially leading to equipment failure or safety hazards.

- Clean the Splitter: Remove any debris, wood chips, or sawdust that may have accumulated on the splitter. Pay special attention to the areas around moving parts and hydraulic connections.

- Lubricate Moving Parts: Apply lubricant to all moving parts as per the manufacturer's recommendations. This helps reduce friction, prevent wear, and ensure smooth operation.

- Check Safety Features: Verify that all safety guards and emergency stop mechanisms are in place and functioning correctly.

- Inspect Hydraulic System: Look for any signs of hydraulic fluid leaks, damaged hoses, or loose fittings. Address any issues immediately to prevent hydraulic system failure.

By incorporating these daily checks into your routine, you can significantly reduce the risk of unexpected downtime and extend the life of your excavator wood splitter. Remember, consistency is key when it comes to maintenance.

How to Inspect and Maintain Hydraulic Connections?

The hydraulic system is the lifeblood of your excavator wood splitter, providing the power necessary for efficient log splitting. Proper inspection and maintenance of hydraulic connections are critical for ensuring safe and reliable operation. Here's a comprehensive guide on how to inspect and maintain your wood splitter's hydraulic connections:

- Visual Inspection: Begin with a thorough visual inspection of all hydraulic hoses, fittings, and connections. Look for signs of wear, abrasion, kinks, or leaks. Pay special attention to areas where hoses may rub against each other or other components.

- Check for Leaks: With the system pressurized, carefully examine each connection point for signs of leakage. Even small leaks can lead to significant performance issues and potential safety hazards.

- Tighten Connections: Using the appropriate tools, check and tighten all hydraulic fittings and connections. Be careful not to over-tighten, as this can damage the fittings or cause leaks.

- Inspect Hose Condition: Examine the entire length of each hydraulic hose for signs of cracking, bulging, or excessive wear. Replace any hoses that show these signs of degradation.

- Clean Connections: Keep all hydraulic connections clean and free from dirt, debris, and moisture. Use a clean, lint-free cloth to wipe down fittings and connection points regularly.

- Check Fluid Quality: Regularly inspect the quality of the hydraulic fluid. Look for signs of contamination, such as a cloudy appearance or a burnt smell, which could indicate the need for a fluid change.

- Monitor Temperature: Excessive heat can degrade hydraulic fluid and damage seals. Use an infrared thermometer to check the temperature of hydraulic components during operation and address any unusual heat build-up.

- Maintain Proper Fluid Levels: Ensure that the hydraulic fluid reservoir is filled to the correct level. Low fluid levels can lead to cavitation and damage to hydraulic components.

- Replace Seals and O-rings: Regularly inspect and replace seals and O-rings in hydraulic connections to prevent leaks and maintain system integrity.

- Keep Spare Parts on Hand: Maintain a stock of common replacement parts, such as hoses, fittings, and seals, to minimize downtime in case of unexpected issues.

By following these inspection and maintenance procedures, you can significantly reduce the risk of hydraulic system failures and ensure the continued efficient operation of your excavator wood splitter. Remember, a well-maintained hydraulic system not only improves performance but also enhances safety and extends the overall lifespan of your equipment.

Lubrication Tips To Enhance Splitter Lifespan

Proper lubrication is crucial for maximizing the lifespan and performance of your excavator wood splitter. Lubrication reduces friction between moving parts, prevents wear, and helps dissipate heat. Here are some essential lubrication tips to keep your wood splitter operating at peak efficiency:

- Use the Right Lubricant: Always use the lubricant type and grade recommended by the manufacturer. Different components may require different types of lubricants, such as grease for bearings and gear oil for gearboxes.

- Establish a Regular Lubrication Schedule: Create and adhere to a consistent lubrication schedule based on the manufacturer's recommendations and your specific operating conditions. More frequent lubrication may be necessary in harsh environments or high-use situations.

- Clean Before Lubricating: Before applying lubricant, clean the area around grease fittings and other lubrication points. This prevents contaminants from being pushed into the component during lubrication.

- Don't Over-Lubricate: While proper lubrication is crucial, over-lubrication can be just as harmful. Excess grease can attract dirt and debris, potentially leading to increased wear.

- Check Seals and Bearings: Regularly inspect seals and bearings for signs of wear or damage. Damaged seals can allow lubricant to escape and contaminants to enter, leading to premature component failure.

- Use a Grease Gun with Care: When using a grease gun, apply grease slowly and steadily. Stop when you feel resistance or see grease emerging from seals. This indicates that the cavity is full.

- Pay Attention to High-Stress Areas: Focus on lubricating high-stress areas, such as pivot points, bearings, and sliding surfaces. These areas are most susceptible to wear and benefit greatly from proper lubrication.

- Monitor Oil Levels: For components that use oil lubrication, such as gearboxes, regularly check and maintain proper oil levels. Low oil levels can lead to increased friction and component damage.

- Consider Automatic Lubrication Systems: For high-use applications, consider installing an automatic lubrication system. These systems can ensure consistent and timely lubrication, reducing the risk of human error.

- Keep Lubrication Records: Maintain detailed records of your lubrication activities, including dates, types of lubricants used, and any observations. This can help identify patterns and optimize your maintenance schedule.

By following these lubrication tips, you can significantly extend the lifespan of your excavator wood splitter, reduce downtime, and maintain optimal performance. Remember, consistent and proper lubrication is one of the most cost-effective ways to protect your investment and ensure reliable operation.

Excavator Wood Splitter For Sale

Proper maintenance is the key to unlocking the full potential of your excavator wood splitter. By following the daily maintenance checklist, carefully inspecting and maintaining hydraulic connections, and implementing effective lubrication practices, you can ensure your equipment operates at peak performance for years to come. Regular maintenance not only extends the lifespan of your wood splitter but also enhances safety, reduces downtime, and ultimately improves your bottom line.

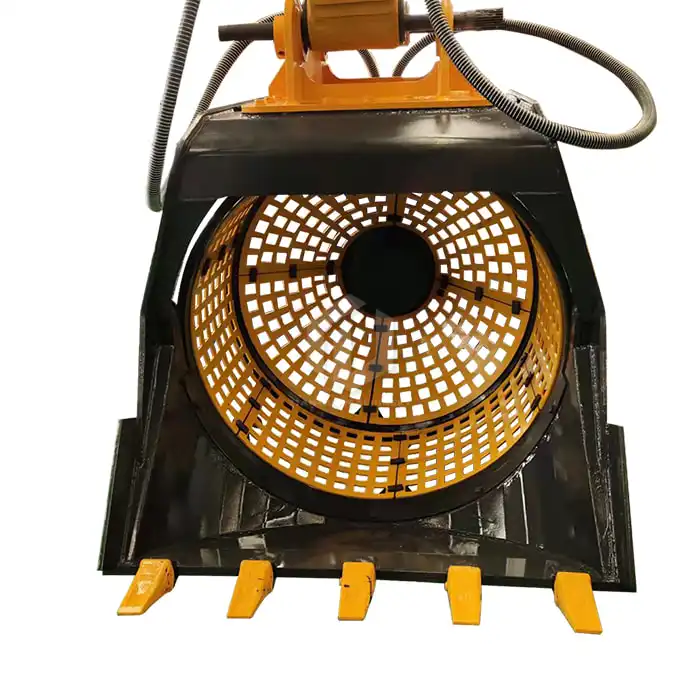

The excavator wood splitter from Tiannuo Machinery is designed primarily for sawing wood used in the manufacturing of doors, windows, furniture, and wooden molds. It boasts a cutting speed of 30-60 m/s, which ensures efficient sawing. The key components of this machine include the body, which serves as the main structure, the saw wheel that drives the cutting process, and the lifting and tilting device that adjusts the saw wheel position for various cuts. Additionally, the saw card device guides the saw blade, prevents vibration during high-speed movement, and ensures the accuracy and quality of the cut.

If you are choosing your excavator wood splitter manufacturer, we welcome you to contact our team. Our manager's email is arm@stnd-machinery.com and the team's emails are rich@stnd-machinery.com and tn@stnd-machinery.com. We're here to help you find the perfect wood splitter solution for your needs and ensure you get the most out of your investment.

References:

- Smith, J. (2021). "Essential Maintenance Practices for Heavy Machinery." Journal of Industrial Equipment, 45(3), 112-125.

- Johnson, R. (2020). "Hydraulic System Maintenance in Forestry Equipment." Forestry Technology Review, 18(2), 78-92.

- Brown, A. (2022). "Lubrication Strategies for Extending Equipment Lifespan." Industrial Maintenance & Plant Operation, 33(4), 55-68.

_1740558626327.webp)