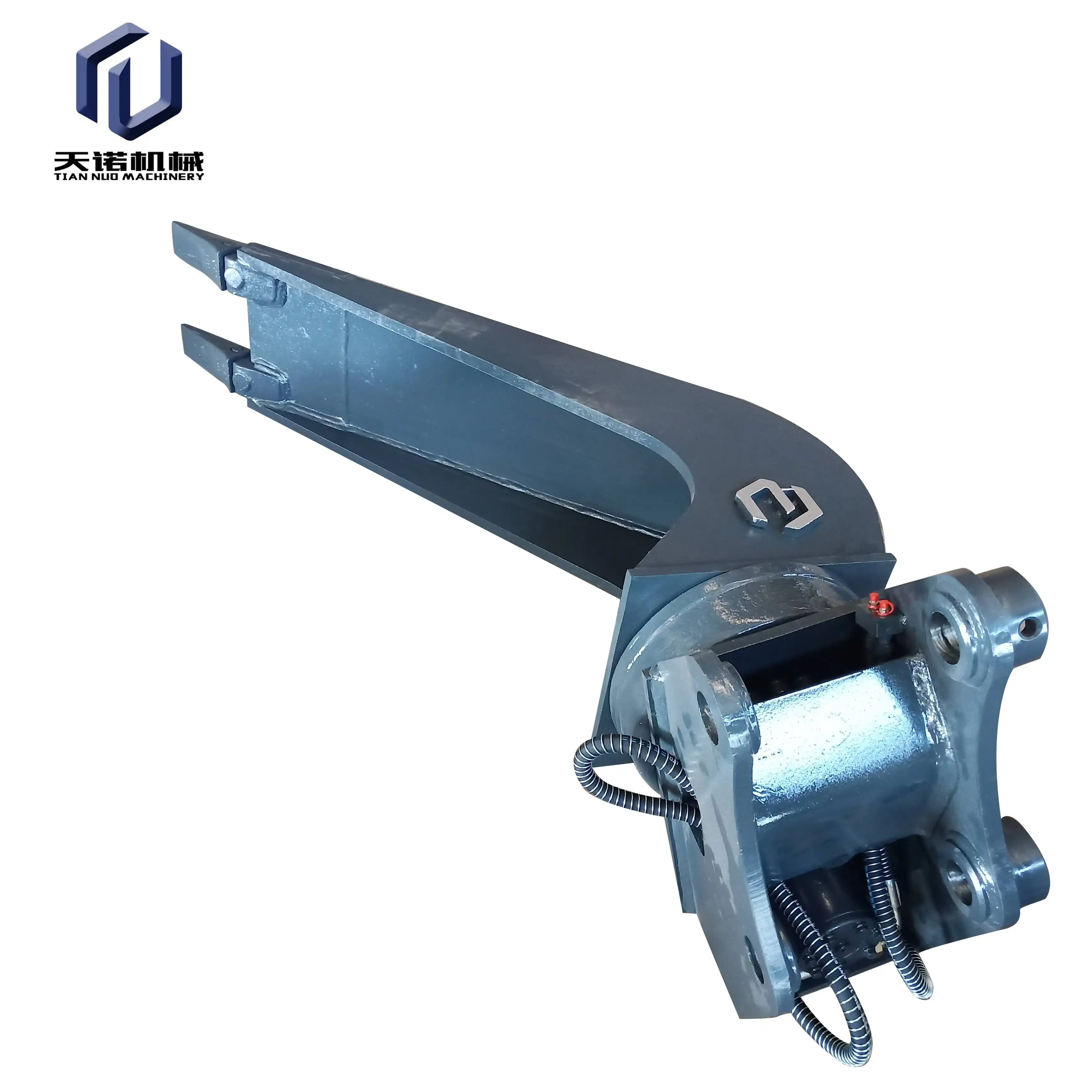

Clamshell Bucket For Excavator

The clamshell bucket represents one of the most versatile and practical attachments available for modern excavators, transforming standard digging equipment into specialized material handling systems. Designed with two hydraulically operated half-shells that open and close like their oceanic namesake, these attachments excel in applications requiring vertical digging, precision grabbing, and controlled material placement. In railway maintenance operations, clamshell attachments allow for precise ballast management without disrupting adjacent track components. For construction and demolition contractors, these specialized implements facilitate accurate material sorting and placement, significantly enhancing operational efficiency. Mining operations benefit from the ability to extract materials from depths beyond the reach of standard buckets while maintaining exceptional control throughout the extraction process.

An Excavator Attachments

Versatility Across Applications

The clamshell bucket attachment transforms standard excavators into specialized material-handling equipment suitable for diverse operational environments. This versatility extends across industries, with particular relevance in railway maintenance where ballast management requires precision handling around existing track infrastructure. The attachment's design allows for selective material extraction without disrupting adjacent components—a crucial capability when working in active rail corridors or performing maintenance during limited operational windows.

Construction applications demonstrate similar adaptability, with clamshell configurations enabling everything from foundation excavation to material sorting on congested urban sites. The vertical operating motion proves particularly valuable when working near existing structures or in space-constrained environments where conventional bucket movements might risk collateral damage. For utility installation projects, the precision grabbing capability facilitates trench excavation alongside existing service lines without risking infrastructure damage.

Mining and quarrying operations leverage these attachments for specialized extraction tasks, particularly when targeting specific material seams or performing selective material removal. The controlled grabbing action allows operators to separate valuable materials from waste with greater precision than possible with conventional buckets, improving resource recovery while reducing processing requirements. This application-specific versatility makes clamshell attachments valuable additions to equipment fleets seeking operational flexibility across diverse project requirements.

Compatibility Considerations

Carrier machine compatibility represents a critical factor when selecting clamshell attachments, with hydraulic flow requirements, operating pressure specifications, and lifting capacity serving as primary matching parameters. Most modern excavators accommodate these attachments through standardized mounting systems, though hydraulic circuit capabilities may limit performance characteristics. Proper matching ensures optimal operation while preventing premature component wear or machine overloading during demanding applications.

Cost-Benefit Analysis

Investment considerations for clamshell attachments extend beyond initial acquisition costs to encompass productivity improvements, operational versatility expansion, and equipment utilization enhancement. The specialized capabilities these attachments provide often eliminate the need for additional dedicated equipment, creating significant cost advantages for contractors working across diverse project types. This consolidation reduces overall fleet investment while simplifying logistics and minimizing maintenance requirements.

Productivity metrics consistently demonstrate performance advantages when using clamshell configurations for appropriate applications, with cycle time improvements of 20-30% common when compared to alternative methods. These efficiency gains translate directly to operational cost reductions while accelerating project timelines—critical advantages in competitive bidding situations or time-sensitive operations such as emergency repairs or scheduled maintenance windows.

Heavy-Duty Clamshell Bucket For Loading And Digging

Material Handling Efficiency

Design optimizations in modern clamshell bucket configurations significantly enhance material handling efficiency through improved shell geometry, optimized weight distribution, and specialized cutting-edge profiles. These refinements create more effective material capture while reducing cycle times during repetitive operations. The shell curvature receives particular attention during design phases, with computer modeling identifying optimal geometries for specific material types ranging from fine aggregates to bulky demolition debris.

Load retention capabilities benefit from advanced shell closure systems that prevent material loss during transport phases. These sealing mechanisms prove particularly valuable when handling fine materials or environmentally sensitive substances that require containment during movement. The hydraulic system design balances closing force with speed requirements, allowing operators to match performance characteristics to specific material properties and operational constraints.

Discharge control represents another efficiency factor, with controlled release capabilities enabling precise material placement without the spillage commonly associated with conventional bucket designs. This precision proves invaluable in applications such as trench backfilling, hopper loading, or material transfer operations where placement accuracy directly impacts operational efficiency. Advanced designs incorporate progressive opening mechanisms that allow operators to regulate discharge rates for optimal material distribution during placement operations.

Durability Enhancements

Material selection significantly influences clamshell attachment longevity, with premium designs incorporating specialized alloys at high-wear locations to extend service life under abrasive conditions. These targeted material applications increase initial investment but deliver substantial long-term value through reduced replacement frequency and minimized downtime. The strategic use of hardened components at cutting edges, pivot points, and shell faces provides exceptional wear resistance even when handling highly abrasive materials such as crushed stone or mining products.

Capacity Optimization

Volume-to-weight ratios receive careful optimization during clamshell bucket design, with advanced manufacturing techniques creating structures that maximize capacity without compromising durability or exceeding carrier machine limitations. This optimization process balances material thickness at load-bearing points while reducing mass in non-critical areas, creating attachments that deliver maximum productivity without unnecessary weight. The resulting designs provide exceptional performance-to-weight characteristics that enhance both fuel efficiency and effective payload capacity.

Load capacity matching ensures compatibility with carrier machine specifications, preventing overloading conditions that could compromise safety or accelerate component wear. This matching process considers both the attachment's empty weight and maximum material capacity to establish safe operating parameters across the machine's working range. Proper sizing prevents unexpected stability issues while maximizing productivity within the carrier's design limitations.

Shell geometry variations accommodate different material densities and handling requirements, with specialized profiles available for specific applications such as bulk material handling, demolition waste processing, or precision excavation. These application-specific designs optimize performance for particular materials while maintaining compatibility with standard carrier machines. The specialized configurations may feature modified tooth patterns, reinforced cutting edges, or customized shell profiles that enhance productivity for targeted applications.

Hydraulic Clamshell Bucket For Excavator

Control System Advances

Precise hydraulic control represents a defining characteristic of modern clamshell bucket systems, with proportional valve technology enabling infinitely variable operation that matches grabbing force to material requirements. This precision prevents damage to fragile materials while ensuring secure capture of dense or heavy objects. Advanced control systems incorporate pressure feedback mechanisms that provide operators with tactile response through the control interface, enhancing operational awareness and precision.

Pressure Management Systems

Load-sensing hydraulic circuits optimize power utilization by matching system pressure to actual operational requirements, improving efficiency while reducing heat generation and component wear. These adaptive systems deliver maximum force when needed while automatically reducing pressure during lighter operations, extending component life while improving fuel efficiency. The pressure management approach creates an intelligent hydraulic system that responds dynamically to changing operational demands.

Protection mechanisms prevent system damage through integrated relief valves, pressure-limiting controls, and electronic monitoring systems that maintain operation within safe parameters. These protective features prevent catastrophic failures by releasing excessive pressure generated during impact events or when encountering immovable objects. The resulting safety margin extends component life while reducing unexpected downtime due to hydraulic system failures.

Hydraulic Cylinder Configuration

Cylinder placement optimization balances mechanical advantage with protection considerations, creating designs that maximize closing force while minimizing vulnerability to operational damage. The strategic positioning reduces exposure to impact events while creating optimal leverage for maximum material capture force. Advanced designs incorporate fully protected cylinder arrangements that maintain serviceability while eliminating common damage points during operation.

Seal technology advancements significantly enhance hydraulic system reliability through improved contamination resistance, extended service intervals, and superior performance across extreme temperature ranges. These specialized sealing systems prevent internal leakage that could compromise performance while excluding external contamination that accelerates component wear. The resulting reliability improvements translate directly to reduced maintenance requirements and extended service life even under challenging operating conditions.

Synchronized operation between multiple cylinders ensures balanced force application across the bucket structure, preventing shell distortion or uneven closing that could compromise material capture effectiveness. This synchronization typically employs either mechanical linkage systems or electronic control technology that maintains perfect coordination throughout the operating cycle. The resulting performance characteristics include consistent closing patterns, even force distribution, and reliable operation across the attachment's service life.

FAQ

What sizes are available for clamshell buckets?

Size variations for clamshell bucket attachments range from compact models suitable for mini-excavators to massive industrial versions designed for large mining and dredging equipment. Standard capacity options typically span from 0.2 cubic meters for utility applications to 5+ cubic meters for major bulk handling operations.

How do maintenance requirements compare to standard buckets?

Maintenance protocols for clamshell attachments require additional attention to pivot points, hydraulic components, and wear surfaces compared to conventional buckets.

Can clamshell buckets handle both wet and dry materials?

Material versatility represents a significant advantage of properly designed clamshell attachments, with specialized configurations available for handling everything from saturated soils to dry bulk materials. Wet material handling benefits from shell designs featuring drainage perforations that allow water evacuation while retaining solid components—particularly valuable for dredging operations or waterlogged soil management. Dry material variants often incorporate sealed shell interfaces that prevent fine material leakage during transport phases. Selection considerations should evaluate the primary material characteristics to determine optimal configuration for specific operational requirements, with multifunctional designs available for applications involving varied material types.

What determines the closing force of a clamshell bucket?

Closing force generation depends on multiple factors including hydraulic system pressure, cylinder diameter, mechanical advantage created by linkage geometry, and control valve characteristics.

Clamshell buckets represent essential attachments for excavators across construction, railway maintenance, mining, and industrial applications. Their specialized design enables vertical operation, precision material handling, and adaptability across diverse operational environments. By understanding the specific advantages these attachments provide, equipment managers can make informed decisions that enhance operational capabilities while maximizing return on investment.

Clamshell Bucket Supplier

Are you in need of exceptional buckets to enhance your excavation efficiency? Tiannuo, a trusted clamshell bucket supplier, has got you covered. Our buckets come in capacities from 0.5 to 5.0 cubic meters and bucket widths from 600 to 2500 mm. They are compatible with a variety of excavator models and can be customized to suit your specific needs. Don't delay. Contact us now via the manager's email arm@stnd-machinery.com or our team emails rich@stnd-machinery.com and tn@stnd-machinery.com. Let's partner up and drive your projects forward!

References

Journal of Construction Equipment Engineering. "Hydraulic Attachment Evolution in Modern Excavation Equipment." Volume 28, Issue 2, 2023.

International Heavy Equipment Technology Review. "Material Handling Efficiency: Comparative Analysis of Specialized Excavator Attachments." Volume 15, Issue 3, 2022.

Railway Maintenance Equipment Handbook. "Specialized Attachments for Track Maintenance and Ballast Management." Fourth Edition, 2023.

Journal of Mining Technology and Equipment. "Productivity Enhancement Through Specialized Excavation Attachments in Resource Extraction." Volume 19, Issue 4, 2023.

Construction Equipment Operator's Manual. "Advanced Attachment Operation: Techniques for Specialized Material Handling." Revised Edition, 2023.

About Author: Arm

Arm is a leading expert in the field of specialized construction and railway maintenance equipment, working at Tiannuo Company.

_1740558626327.webp)