Best Excavator Grab Arm Quotation for Construction

When it comes to construction projects, having the right equipment can make all the difference in terms of efficiency and productivity. One crucial piece of machinery that often plays a significant role in various construction tasks is the excavator grab arm. This versatile attachment enhances the capabilities of excavators, allowing them to handle a wide range of materials with precision and ease.

What factors influence the cost of an excavator grab arm?

The price of an excavator grab arm can vary significantly based on several key factors. Understanding these elements can help construction professionals make informed decisions when seeking quotations for their projects.

1. Size and Capacity: The size and capacity of the grab arm are primary determinants of its cost. Larger grab arms with higher lifting capacities are generally more expensive due to the increased materials and engineering required in their construction. The size of the grab arm should be compatible with the excavator it will be attached to, as well as the specific requirements of the construction project.

2. Material Quality: The materials used in manufacturing the grab arm significantly impact its durability, performance, and price. High-grade steel and other premium materials offer better resistance to wear and tear, resulting in a longer lifespan but at a higher initial cost. Conversely, grab arms made from lower-quality materials may be less expensive upfront but might require more frequent replacements or repairs.

3. Design Complexity: The design of the excavator grab arm can range from simple to highly sophisticated. More complex designs with additional features such as hydraulic rotation, multiple gripping points, or specialized attachments for specific tasks will generally command a higher price. These advanced designs often offer improved versatility and efficiency, which can justify the additional cost for certain applications.

4. Brand Reputation: Well-established brands with a history of producing high-quality excavator attachments often charge premium prices for their grab arms. While these may come at a higher initial cost, they often offer better reliability, performance, and after-sales support, which can result in lower long-term expenses.

5. Customization Options: Many manufacturers offer customization options for grab arms to meet specific project requirements. These can include modifications to the arm length, gripping force, or the addition of specialized features. While customization can increase the overall cost, it ensures that the grab arm is optimally suited for its intended use, potentially improving efficiency and reducing operational costs in the long run.

6. Technology Integration: Some modern grab arms incorporate advanced technologies such as sensors for precise control, monitoring systems for maintenance scheduling, or compatibility with GPS and machine control systems. These technological enhancements can significantly increase the initial cost but may offer substantial benefits in terms of productivity and operational efficiency.

7. Market Demand and Supply: Like any product, its price can be influenced by market dynamics. High demand coupled with limited supply can drive prices up, while oversupply or reduced demand may lead to more competitive pricing. Seasonal variations in construction activity can also impact pricing, with potential discounts available during slower periods.

8. Regulatory Compliance: Grab arms must often meet specific safety and environmental standards, which can vary by region. Compliance with these regulations may require additional features or certifications, potentially increasing the overall cost. However, ensuring compliance is crucial for legal operation and can prevent costly fines or project delays.

How to compare excavator grab arm prices for construction projects?

When comparing excavator grab arm prices for construction projects, it's essential to look beyond the initial price tag and consider the overall value and suitability for your specific needs. Here are some strategies to help you make an informed comparison:

1. Assess Total Cost of Ownership: While the upfront cost is important, it's crucial to consider the total cost of ownership over the lifespan of the grab arm. This includes factors such as maintenance requirements, expected durability, and potential downtime for repairs. A higher-priced grab arm that offers better reliability and requires less maintenance may prove more cost-effective in the long run.

2. Compare Specifications: Carefully review the technical specifications of different grab arms to ensure you're comparing like-for-like products. Pay attention to key metrics such as lifting capacity, operating weight, and compatibility with your existing excavator model. This will help you avoid the pitfall of choosing a lower-priced option that doesn't meet your project requirements.

3. Consider Versatility: Evaluate how versatile each grab arm is in terms of the range of tasks it can perform. A more versatile grab arm might command a higher price but could be more valuable if it can be used across various projects or applications, potentially reducing the need for multiple specialized attachments.

4. Analyze Productivity Potential: Consider how each grab arm might impact your overall productivity. Features that enhance precision, speed, or ease of operation can lead to significant time savings and increased efficiency on the job site. These productivity gains should be factored into your price comparison.

5. Evaluate Manufacturer Support: Look into the level of support offered by different manufacturers. This includes factors such as warranty coverage, availability of spare parts, and access to technical support. A manufacturer that provides comprehensive support may offer better value, even if their grab arm is priced higher.

6. Seek Multiple Quotations: Obtain quotations from several reputable suppliers or manufacturers. This will give you a better understanding of the market rate for the type of grab arm you need and may reveal opportunities for negotiation or competitive pricing.

7. Consider Rental Options: For short-term projects or to test different models, renting an excavator grab arm might be a cost-effective alternative to purchasing. Compare rental rates with purchase prices, taking into account the duration of your project and potential future needs.

8. Review User Feedback: Look for reviews or testimonials from other construction professionals who have used the grab arms you're considering. Real-world experiences can provide valuable insights into performance, reliability, and overall value that may not be apparent from specifications alone.

Why investing in a high-quality grab arm improves construction efficiency?

Investing in a high-quality excavator grab arm can significantly enhance construction efficiency in numerous ways, ultimately leading to improved project outcomes and potential cost savings. Here's why opting for a premium grab arm can be a wise decision for construction professionals:

1. Enhanced Durability and Reliability: High-quality grab arms are typically constructed using superior materials and manufacturing processes. This results in a more durable product that can withstand the rigors of demanding construction environments. Increased reliability means less downtime for repairs and maintenance, allowing for more consistent and efficient operation throughout the project lifecycle.

2. Improved Precision and Control: Premium grab arms often feature advanced hydraulic systems and design elements that provide operators with greater precision and control. This enhanced maneuverability allows for more accurate material handling, reducing the time and effort required for tasks such as sorting, loading, and placement of materials. The improved accuracy can also help minimize waste and rework, further contributing to project efficiency.

3. Versatility in Applications: High-quality grab arms are often designed with versatility in mind, allowing them to handle a wide range of materials and perform various tasks. This versatility can reduce the need for multiple specialized attachments, streamlining equipment management and reducing setup times between different operations. The ability to quickly adapt to different project requirements can significantly improve overall construction efficiency.

4. Increased Lifting Capacity: Premium grab arms typically offer higher lifting capacities compared to their lower-quality counterparts. This increased capacity allows for the handling of larger loads, reducing the number of cycles required to complete material handling tasks. The ability to move more material in less time directly translates to improved efficiency and productivity on the construction site.

5. Advanced Safety Features: High-quality grab arms often incorporate advanced safety features such as load-holding valves, overload protection systems, and improved visibility designs. These safety enhancements not only protect workers and equipment but also contribute to efficiency by reducing the likelihood of accidents and the associated downtime.

6. Compatibility with Modern Technologies: Premium grab arms are more likely to be compatible with cutting-edge construction technologies such as GPS-guided systems, telematics, and machine control software. This integration can lead to more precise and efficient operations, as well as improved project planning and management through real-time data collection and analysis.

7. Reduced Fuel Consumption: Well-designed, high-quality grab arms often operate more efficiently, requiring less hydraulic power to perform tasks. This can result in reduced fuel consumption for the excavator, leading to cost savings and a smaller environmental footprint over the life of the equipment.

8. Longer Lifespan: The superior construction and materials used in high-quality grab arms typically result in a longer operational lifespan. This extended service life means fewer replacements over time, reducing long-term costs and minimizing disruptions to construction operations that would otherwise occur during equipment changeovers.

9. Enhanced Operator Comfort: Premium grab arms often feature ergonomic designs and smoother operation, which can reduce operator fatigue and increase productivity over long work shifts. Comfortable operators are more likely to maintain high levels of efficiency throughout the workday, contributing to overall project productivity.

Tiannuo Machinery Excavator Grab Arm Quotation

Selecting the right grab arm is a crucial decision that can significantly impact the efficiency and success of your construction projects. By carefully considering the factors that influence cost, comparing options thoroughly, and recognizing the benefits of investing in quality, you can make an informed choice that aligns with your project requirements and long-term goals.

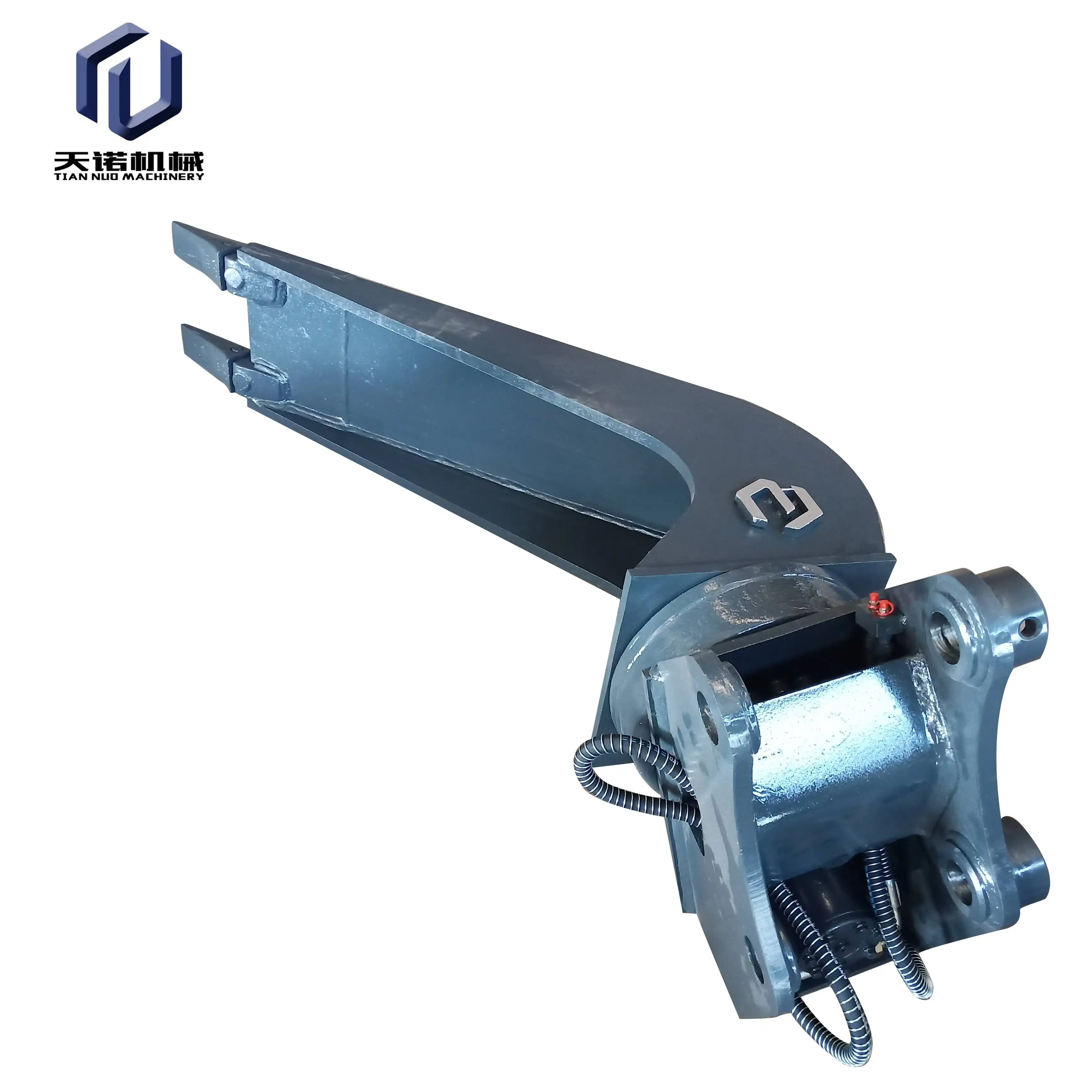

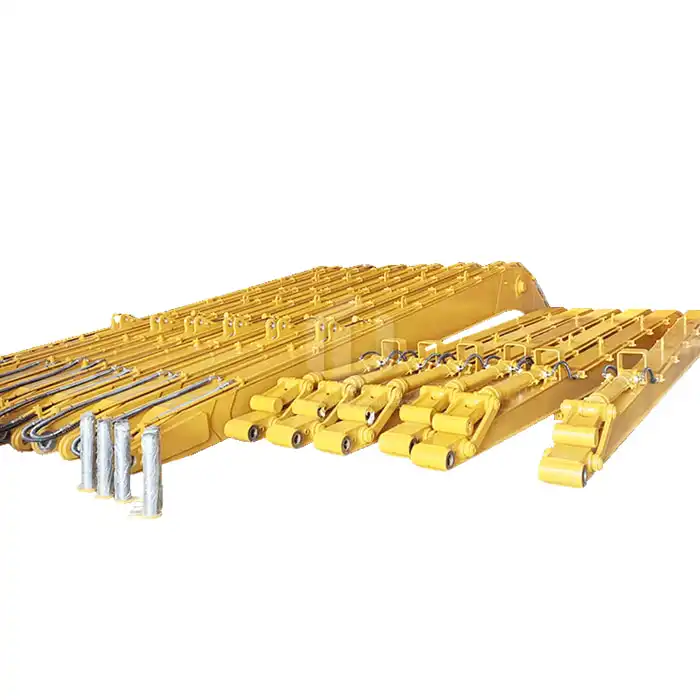

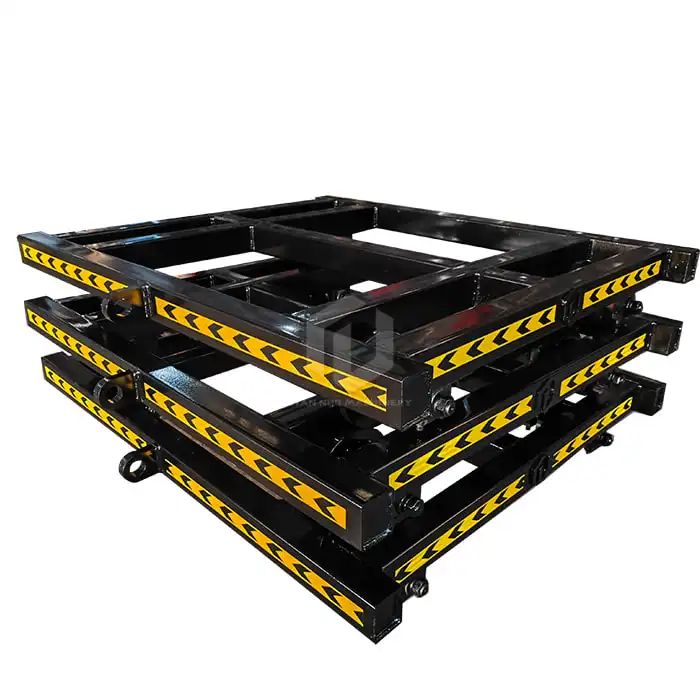

Tiannuo Machinery offers a comprehensive range of grab arms designed to meet the diverse needs of modern construction projects. Our grab arms are engineered for optimal performance in various applications, including dock unloading, railway transportation unloading, and waste steel handling. With beveling welding to prevent deformation, our products ensure durability and reliability in demanding work environments.

We provide grab arms suitable for excavators ranging from 12 to 49 tons, ensuring compatibility with a wide range of machinery. Understanding that each project has unique requirements, we offer customizable designs that allow you to tailor the arm length, lifting capacity, and attachment configurations to your specific needs.

If you're in the process of selecting an excavator grab arm manufacturer, we invite you to experience the Tiannuo difference. Our team of experts is ready to assist you in finding the perfect solution for your construction needs. For personalized quotations and detailed product information, please don't hesitate to reach out to our manager at arm@stnd-machinery.com. Additionally, our dedicated team members are available at rich@stnd-machinery.com and tn@stnd-machinery.com to answer any questions and provide comprehensive support.

Choose Tiannuo Machinery for grab arms that combine innovation, quality, and customization to elevate your construction projects to new heights of efficiency and productivity.

References

Anderson, T. & Harris, K. (2020). Heavy Equipment Attachments: A Practical Guide for Construction Professionals. Heavy Machinery Press.

Chen, Y. & Liu, X. (2021). Optimizing Excavator Performance Through Advanced Attachment Design. Construction Technology Review.

European Construction Equipment Association. (2022). Safety and Efficiency Standards for Excavator Attachments.

Kumar, R. & Singh, P. (2019). Material Handling in Construction: Challenges and Solutions. Journal of Industrial Engineering.