Why is positioning mode important for the railway sleeper changer's stability?

Railway maintenance is a critical aspect of ensuring safe and efficient transportation systems. Among the various maintenance tasks, replacing railway sleepers is a crucial operation that requires precision and stability. The railway sleeper changer, a specialized machine designed for this purpose, plays a vital role in this process. One of the key features that contribute to its effectiveness is the positioning mode. In this article, we'll explore why the positioning mode is so important for its stability and how it impacts the overall maintenance process.

Railway sleepers, also known as railroad ties, are the rectangular supports laid perpendicular to the rails. They play a crucial role in distributing the load from the rails to the track ballast and underlying ground, maintaining the correct gauge between the rails, and ensuring overall track stability. Over time, these sleepers can deteriorate due to various factors such as weather conditions, heavy loads, and regular wear and tear. This is where the railway sleeper changer comes into play, efficiently replacing worn-out sleepers with new ones.

Prevents Derailing

One of the primary reasons why the positioning mode is crucial for the railway sleeper changer's stability is its role in preventing derailment. When operating on railway tracks, the risk of derailment is always a significant concern. The positioning mode addresses this issue by providing a secure and stable platform for the machine to work on.

In the positioning mode, its chassis is equipped with track limit wheels. These specialized wheels are designed to fit snugly against the rails, effectively preventing the machine from moving off the track. This design feature ensures that the sleeper changer remains firmly in place during the entire operation, even when subjected to the forces and vibrations associated with sleeper replacement.

The prevention of derailment is not just a matter of equipment safety; it's also crucial for the safety of the workers operating the machine and those in the vicinity. A derailed sleeper changer could cause significant damage to the track, delay operations, and potentially lead to accidents. By maintaining a stable position on the track, the positioning mode significantly reduces these risks, allowing maintenance crews to work with greater confidence and efficiency.

Moreover, the positioning mode's anti-derailment feature is particularly valuable when working on curved sections of track or in areas with slight irregularities. These challenging conditions might otherwise increase the risk of the machine slipping off the rails. However, with the track limit wheels engaged in positioning mode, the railway sleeper changer can navigate these sections safely, ensuring uninterrupted maintenance operations.

Prevents Track Damage

Another critical aspect of the positioning mode's importance lies in its ability to prevent track damage during the sleeper replacement process. Railway tracks are precision-engineered structures, and any damage during maintenance can lead to costly repairs and potential safety issues. The positioning mode of the railway sleeper changer plays a significant role in mitigating this risk.

When the sleeper changer is in positioning mode, its weight is distributed more evenly across the track. This even distribution helps prevent excessive pressure on any single point of the track, which could otherwise lead to deformation or damage. The track limit wheels, engaged in this mode, are designed to interface with the rails in a way that minimizes wear and tear.

Furthermore, the stability provided by the positioning mode allows for more controlled movements of the sleeper changer. This control is crucial when lifting and placing sleepers, as sudden or uncontrolled movements could potentially damage the track or surrounding infrastructure. By maintaining a stable platform, the positioning mode enables operators to perform these delicate operations with greater precision and less risk of accidental impacts.

The prevention of track damage is not just about maintaining the physical integrity of the rails and sleepers. It also has significant economic implications. Damage to tracks can lead to speed restrictions, which in turn can cause delays and disrupt railway schedules. By minimizing the risk of such damage, the positioning mode of the railway sleeper changer helps maintain the overall efficiency of the railway network.

Additionally, the positioning mode's role in preventing track damage extends to the protection of the track's geometry. Maintaining the correct alignment and level of the track is crucial for the smooth and safe operation of trains. The stable platform provided by the positioning mode allows for more accurate placement of new sleepers, helping to maintain the track's geometric integrity throughout the replacement process.

Supports Precision in Sleeper Replacement

Precision is paramount in railway maintenance, particularly when it comes to sleeper replacement. The positioning mode of the railway sleeper changer plays a crucial role in supporting this precision, ensuring that each sleeper is replaced accurately and efficiently.

When in positioning mode, the railway sleeper changer provides a stable base from which to operate. This stability is essential for the precise lifting and placement of sleepers. The machine's arms and grippers, responsible for handling the sleepers, can operate with greater accuracy when the base is firmly secured to the track. This precision is critical, as even small errors in sleeper placement can accumulate over time, potentially affecting the track's alignment and the comfort and safety of train journeys.

The positioning mode also supports precision by allowing for fine adjustments during the replacement process. Operators can make minute movements to ensure that new sleepers are placed exactly where they need to be. This level of control is particularly important when dealing with different types of sleepers or when working on sections of track with specific requirements.

Moreover, the precision supported by the positioning mode contributes to the longevity of the newly installed sleepers. Correct placement ensures that the load is distributed evenly across the sleeper, preventing premature wear and extending the life of both the sleeper and the surrounding track structure. This precision ultimately leads to more durable and reliable railway infrastructure.

The positioning mode's contribution to precision also extends to the efficiency of the overall maintenance operation. By enabling accurate sleeper replacement, it reduces the need for follow-up adjustments or corrections. This not only saves time during the immediate maintenance task but also minimizes the need for future maintenance interventions, leading to more efficient use of resources and less disruption to railway services.

Additionally, the precision supported by the positioning mode is crucial when working with modern concrete sleepers. These sleepers often have pre-stressed reinforcement and precise dimensions that require accurate handling and placement. The stability provided by the positioning mode ensures that these high-tech components are installed correctly, maximizing their performance and lifespan.

Railway Sleeper Changer For Sale

The positioning mode of a railway sleeper changer is not just a feature; it's a critical component that significantly enhances the safety, efficiency, and precision of railway maintenance operations. By preventing derailment, minimizing track damage, and supporting precise sleeper replacement, this mode ensures that maintenance tasks are carried out effectively and with minimal risk.

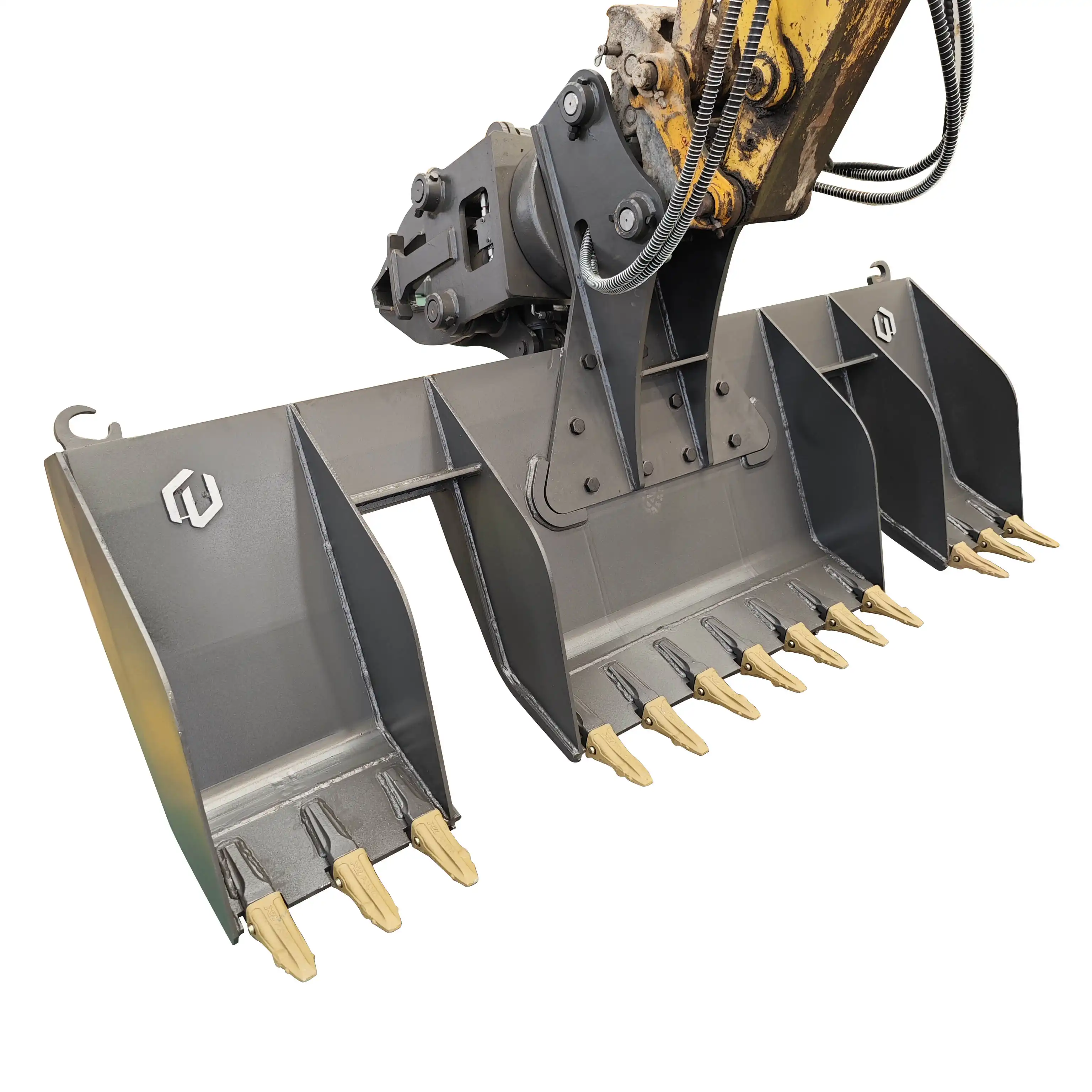

Tiannuo Machinery's railway sleeper changer exemplifies the importance of this feature. Their machine offers two primary walking modes: Two-Wheel Drive and Positioning Mode. The Two-Wheel Drive mode, with its track wheels, allows for speeds up to 15 km/h, enhancing operational efficiency. The Positioning Mode, featuring track limit wheels, prevents derailing and ensures stability during operation.

Designed to be compatible with standard track gauges of 1435/1520 mm, Tiannuo's railway sleeper changer meets the requirements of various railway networks. Its two drive wheels provide sufficient power while enhancing mobility and traversability. These design features ensure that the machine maintains operational efficiency while guaranteeing safety and flexibility.

If you're in the market for a railway sleeper changer that prioritizes stability, precision, and efficiency, Tiannuo Machinery could be your ideal choice. For more information or to discuss your specific needs, don't hesitate to reach out. Contact our manager at arm@stnd-machinery.com, or get in touch with our team at rich@stnd-machinery.com and tn@stnd-machinery.com. Let Tiannuo Machinery help you enhance your railway maintenance operations with our state-of-the-art railway sleeper changer.

References:

- Kaewunruen, S., & Remennikov, A. M. (2010). Dynamic crack propagations in prestressed concrete sleepers in railway track systems subjected to severe impact loads. Journal of structural engineering, 136(6), 749-754.

- Lam, H. F., & Wong, M. T. (2018). Railway ballast damage detection by nonlinear vibration-based techniques. Structural Health Monitoring, 17(3), 706-724.

- Mundrey, J. S. (2017). Railway track engineering. Tata McGraw-Hill Education.

- Profillidis, V. A. (2014). Railway management and engineering. Ashgate Publishing, Ltd.

- Esveld, C. (2001). Modern railway track (Vol. 385). Zaltbommel: MRT-productions.