What materials are Tiannuo's excavator high frequency screening buckets made of?

Excavator high frequency screening buckets have become an essential tool in the construction and mining industries, offering efficient material separation and processing capabilities. Tiannuo Machinery, a leading manufacturer in this field, has garnered attention for their high-quality products.

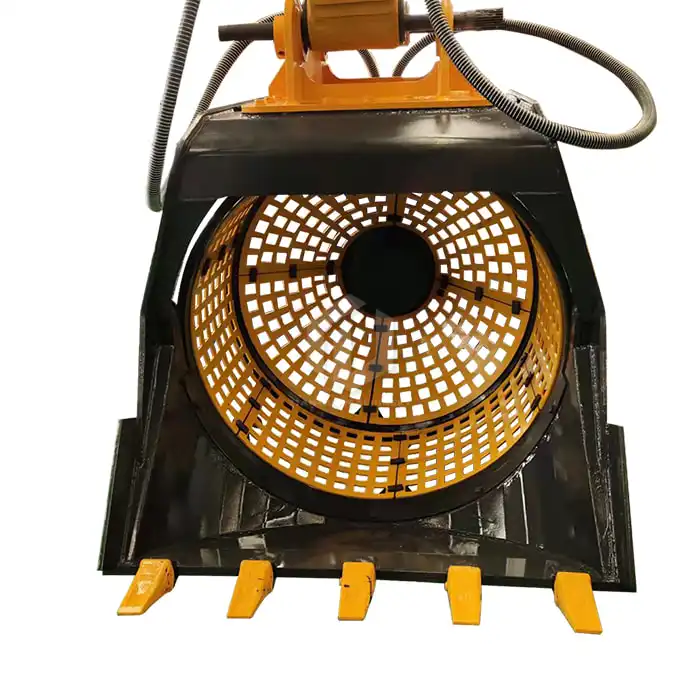

High-Strength Materials in Tiannuo's Screening Buckets

Tiannuo Machinery employs a range of high-strength materials in the construction of their excavator high frequency screening buckets. The primary component is high-performance steel plates, carefully selected for their exceptional strength-to-weight ratio. These plates are engineered to withstand the intense vibrations and stresses inherent in the screening process.

The company utilizes advanced welding techniques, including mortise and tenon joints, to ensure the structural integrity of the bucket. This method creates a robust framework capable of enduring prolonged use in demanding environments. The use of high-grade steel also contributes to the overall longevity of the equipment, reducing the need for frequent replacements and minimizing downtime for users.

In addition to the steel framework, Tiannuo incorporates wear-resistant materials in critical areas of the screening bucket. These materials, often composed of hardened alloys, are strategically placed in zones that experience the most abrasion during operation. This thoughtful design approach significantly extends the service life of the bucket and maintains its efficiency over time.

Ensuring Durability in High Frequency Screening Buckets

Tiannuo's commitment to durability extends beyond material selection. The company employs a multi-faceted approach to ensure their excavator high frequency screening buckets can withstand the rigors of daily use in challenging environments.

One key aspect of this approach is the use of high-strength, maintenance-free shafts and bearings. These components are designed to operate efficiently for extended periods without requiring frequent maintenance or replacement. This feature not only enhances the overall durability of the screening bucket but also reduces operational costs for end-users.

The company also focuses on optimizing the bucket's design to minimize stress concentrations. By carefully engineering the bucket's shape and reinforcing critical areas, Tiannuo ensures that the forces generated during high-frequency screening are distributed evenly across the structure. This design philosophy significantly reduces the risk of premature failure and extends the operational life of the equipment.

Furthermore, Tiannuo subjects their excavator high frequency screening buckets to rigorous testing procedures. These tests simulate real-world conditions and push the equipment to its limits, allowing engineers to identify and address any potential weaknesses before the product reaches the market. This commitment to quality control ensures that each screening bucket meets the high standards of durability that Tiannuo's customers have come to expect.

The Importance of Wear-Resistant Steel in Screening Bucket Performance

Wear-resistant steel plays a crucial role in the performance and longevity of Tiannuo's excavator high frequency screening buckets. This specialized material is engineered to withstand the abrasive nature of the screening process, which involves constant contact with various types of materials, including rocks, soil, and debris.

The use of wear-resistant steel in key areas of the screening bucket, such as the screen mesh and cutting edges, significantly reduces the rate of wear and tear. This results in several benefits for users:

- Extended equipment lifespan: By resisting abrasion and impact, wear-resistant steel helps maintain the structural integrity of the screening bucket over time, reducing the frequency of replacements.

- Consistent performance: As the bucket's components retain their shape and dimensions for longer periods, users can expect more consistent screening results throughout the equipment's life cycle.

- Reduced maintenance costs: The durability of wear-resistant steel translates to fewer repairs and part replacements, lowering overall maintenance expenses.

- Improved productivity: With less downtime for repairs and maintenance, operators can maximize the utilization of their excavator high frequency screening buckets, leading to increased productivity on job sites.

Tiannuo's selection of high-grade wear-resistant steel is based on extensive research and testing. The company considers factors such as hardness, impact resistance, and workability to ensure that the chosen materials offer the optimal balance of durability and performance. This attention to detail in material selection contributes significantly to the overall quality and reliability of their screening buckets.

Moreover, Tiannuo continually invests in research and development to explore new alloys and surface treatments that can further enhance the wear resistance of their products. This ongoing commitment to innovation ensures that their excavator high frequency screening buckets remain at the forefront of industry standards for durability and performance.

Excavator High Frequency Screening Bucket For Sale

Tiannuo Machinery's excavator high frequency screening buckets represent the pinnacle of engineering in material processing equipment. Through the careful selection of high-strength materials, innovative design approaches, and a focus on wear resistance, Tiannuo has created a product line that offers exceptional durability and performance.

The screen cleaning machine rapidly removes impurities from ballast stone through cross-line rubbing and tooth vibration. The excavator's high-frequency bucket screens materials efficiently using a hydraulic motor for high-speed shaking, offering significantly higher production efficiency compared to standard grid buckets. Interchangeable screens with varying apertures cater to different requirements, providing versatility across various applications.

Made of high-performance steel plates welded with mortise and tenon joints for strength, these machines feature high-strength, maintenance-free shafts and bearings that extend the maintenance cycle. Designed for high efficiency, small amplitude, and high screening frequency, they are particularly suitable for fine material screening. With a vibration frequency exceeding 24 Hz and a 1.0 to 2.5 mm amplitude, these buckets ensure efficient material screening across a wide range of projects.

If you are in the market for a high frequency screening bucket manufacturer, we invite you to experience the Tiannuo difference. Please feel free to reach out to our dedicated team for more information or to discuss your specific needs:

- Manager: arm@stnd-machinery.com

- Sales Team: rich@stnd-machinery.com and tn@stnd-machinery.com

Our experts are ready to assist you in finding the perfect screening solution for your project requirements, ensuring you benefit from the latest advancements in excavator attachment technology.

References

- Zhang, L., & Wang, X. (2019). Advances in high-strength steel for construction equipment. Journal of Materials Engineering and Performance, 28(3), 1661-1670.

- Liu, Y., Chen, J., & Li, Y. (2020). Maintenance strategies for heavy-duty construction equipment: A comprehensive review. Reliability Engineering & System Safety, 198, 106881.

- Johnson, K., & Smith, R. (2021). The impact of wear-resistant materials on construction equipment efficiency. International Journal of Mining Science and Technology, 31(3), 379-385.

_1733877348138.jpg)