What is the purpose of a ballast regulator?

A ballast plow serves as an essential tool in railway maintenance operations, designed specifically to manage, distribute, and shape the crushed stone or gravel (ballast) that forms the foundation of railway tracks. Its primary purpose is to ensure proper track alignment and stability by effectively redistributing ballast material along the railway corridor. This critical maintenance equipment helps maintain the structural integrity of the track bed, preventing track misalignment and ensuring safe train operations. By efficiently moving excess ballast from the center of the track to the shoulders or clearing it from the track area altogether, they help maintain proper drainage, reduce vegetation growth, and extend the lifespan of railway infrastructure. Modern plows like those manufactured by Tiannuo Machinery are engineered with adjustable angles and robust construction to handle various track conditions, making them indispensable for railway maintenance crews working to maintain network reliability and operational safety across diverse terrain and environmental conditions.

What Does a Ballast Plow Do in Railway Maintenance?

Ensuring Track Stability and Alignment

The ballast layer beneath and around railway tracks serves as a critical foundation that distributes the weight of passing trains and maintains proper track geometry. Over time, this ballast can shift due to vibrations, weather conditions, and the constant pressure from train traffic. A ballast plow systematically redistributes this material to maintain the optimal profile required for safe train operations.

The equipment works by precisely moving excess ballast from areas where it has accumulated to regions where it's needed. This redistribution process helps prevent track misalignment issues that could potentially lead to derailments or excessive wear on train wheels and track components. By maintaining consistent ballast profiles, the plow helps ensure that tracks remain level and properly aligned according to engineering specifications.

Improving Drainage and Preventing Track Degradation

Railway tracks require proper drainage to function effectively and maintain structural integrity. When ballast becomes clogged with debris or improperly distributed, water can accumulate around the tracks, leading to erosion, frost heave in colder climates, and accelerated degradation of wooden ties and other track components.

A properly deployed ballast plow clears drainage paths along the track, ensuring that water flows away from critical infrastructure rather than pooling around it. This drainage management function is particularly important during rainy seasons or in geographical areas prone to heavy precipitation. By facilitating proper water flow, the plow helps extend the lifespan of the entire track structure and reduces the frequency of major maintenance interventions.

Vegetation Control and Safety Enhancement

Excess ballast that spills onto walkways or accumulates in unintended areas can create safety hazards for railway workers and potentially interfere with track circuits and signaling equipment. Furthermore, unmanaged ballast creates environments where vegetation can take root, eventually leading to track deterioration.

The ballast plow efficiently clears these areas, creating clean walkways for maintenance personnel and preventing vegetation growth that could compromise track integrity. This vegetation management aspect is particularly valuable in reducing fire risks during dry seasons and maintaining clear sightlines for train operators. By keeping the track corridor well-maintained, the plow contributes significantly to the overall safety of railway operations.

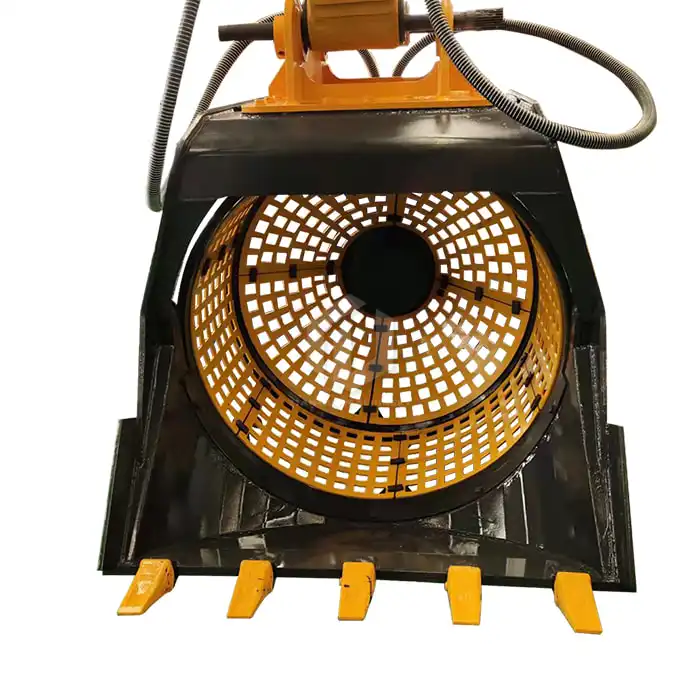

What Are the Key Components of a Ballast Plow?

Blade Systems and Adjustment Mechanisms

The core component of any effective ballast plow is its blade system. Modern plows like those manufactured by Tiannuo feature high-strength alloy steel blades designed to withstand the abrasive nature of ballast materials while maintaining their shape and effectiveness through extended use cycles. These blades are engineered with specific angles and profiles optimized for different ballast management tasks.

What sets quality plows apart is their adjustment mechanisms. Tiannuo's ballast plows incorporate hydraulic control systems that allow operators to modify the angle and position of the blades based on specific maintenance requirements. This adjustability enables the equipment to adapt to various track configurations and ballast conditions. The inclination angle can be adjusted to 8° as needed, allowing for precise ballast profiling regardless of the specific maintenance challenge. This adaptability translates to increased efficiency and more consistent results across diverse railway environments.

Mounting Frameworks and Attachment Systems

For optimal functionality, ballast plows require robust mounting frameworks that connect them securely to excavators or other host machines. The mounting system must balance strength with flexibility, allowing the plow to follow the contours of the track while resisting the significant forces generated during operation.

Tiannuo's ballast plows feature mounting frameworks compatible with excavators ranging from 7-15 tons, making them versatile additions to existing maintenance fleets. These frameworks incorporate reinforced connection points and stress-distributing designs that prevent damage to both the plow and the host machine during operation. The 360° rotation capability further enhances the versatility of these attachment systems, allowing operators to position the plow precisely for different maintenance scenarios without repositioning the entire host machine.

How Does a Ballast Regulator Work with an Excavator Ballast Plow?

Complementary Functions in Track Maintenance

While ballast plows and regulators serve related purposes, they perform distinct functions that complement each other in comprehensive track maintenance operations. Ballast plows, particularly those mounted on excavators like Tiannuo's models, excel at heavy-duty redistribution and initial shaping of ballast materials. They're especially effective at clearing excess ballast from the track center and positioning it where needed along the shoulders.

Ballast regulators, by contrast, typically perform more refined finishing work. After the excavator-mounted ballast plow has completed the major redistribution tasks, regulators sweep through to create the final, precisely shaped ballast profile. This two-stage approach maximizes efficiency by allowing each piece of equipment to focus on the tasks it performs best. The excavator's power and maneuverability make it ideal for the heavier initial work, while the regulator's specialized tools create the finished profile needed for optimal track performance.

Adaptation to Different Track Conditions

Railway networks encompass diverse environments with varying ballast conditions, track configurations, and maintenance challenges. The combination of excavator-mounted ballast plows and regulators provides maintenance teams with the flexibility to adapt to these different conditions.

Tiannuo's excavator ballast plows are designed with adaptability in mind, featuring adjustable working perspectives and compatibility with various excavator sizes (7-15 tons). This flexibility allows maintenance teams to select the appropriate equipment configuration based on the specific requirements of each section of track. In areas with severe ballast displacement or heavy vegetation intrusion, the excavator plow's power makes it the primary tool. For sections requiring only minor profile adjustments, the regulator might handle the entire task. This adaptive approach ensures that maintenance resources are deployed efficiently across the railway network, maximizing the impact of maintenance budgets and personnel.

FAQ

1. How often should ballast plowing be performed?

Ballast plowing frequency varies based on track usage, environmental conditions, and regulatory requirements. High-traffic mainlines may require quarterly or bi-annual plowing, while less-traveled routes might need attention only annually. Inspections should guide maintenance scheduling, with additional plowing performed after extreme weather events or when visual inspections indicate ballast displacement.

2. Can ballast plows work in all weather conditions?

Modern ballast plows like Tiannuo's models can operate in most weather conditions, though efficiency may decrease in extreme situations. Snow and ice can complicate operations but rarely prevent them entirely. Heavy rain may temporarily halt work due to reduced visibility and drainage concerns. The equipment itself is designed to withstand various weather challenges, with high-strength alloy construction that resists corrosion and damage from environmental exposure.

3 . What maintenance does a ballast plow require?

Regular maintenance ensures optimal ballast plow performance and longevity. Daily inspections should check for blade wear, hydraulic leaks, and mounting system integrity. Blades require periodic sharpening or replacement depending on usage intensity and ballast composition. Hydraulic systems need fluid checks and filter replacements according to manufacturer schedules. Following Tiannuo's maintenance guidelines extends equipment lifespan and maintains operational efficiency.

Looking to optimize your railway maintenance? Tiannuo's ballast plow is the perfect tool for machines weighing 5 to 10 tons, with a track gauge of 1435 mm. It measures 2800 mm in width and 460 mm in height and operates at an inclination angle of 8°. This plow is designed to be used in conjunction with sleeper clamps for efficient ballast management. Ready to take the next step? Contact our team manager at arm@stnd-machinery.com, or get in touch with our other team members at rich@stnd-machinery.com and tn@stnd-machinery.com. Together, we can ensure your tracks are maintained efficiently.

References

Railway Track Maintenance: Principles and Practice. American Railway Engineering Association, 2023.

Modern Railway Track Maintenance Equipment. International Railway Journal, Vol. 45, 2022.

Ballast Maintenance Techniques for Enhanced Track Stability. Journal of Railway Engineering, Vol. 18, 2024.

Railway Engineering Handbook: Maintenance of Way and Structures. International Association of Railway Maintenance, 2023.

Comprehensive Guide to Railway Ballast Management. Institute of Railway Technology, 2022.

About Author: Arm

Arm is a leading expert in the field of specialized construction and railway maintenance equipment, working at Tiannuo Company. Tiannuo specializes in manufacturing a wide range of products, including railway maintenance equipment like railway sleeper changing machines and screening machines, excavator modification equipment such as excavator lifting cabs, various engineering arms for excavators, excavator accessories like digging buckets, and engineering vehicle auxiliary equipment like loader buckets.