What is a loader arm extension?

In the world of heavy machinery and construction equipment, loader arm extensions play a crucial role in enhancing the capabilities of various types of loaders. These essential attachments are designed to increase the reach and versatility of loaders, allowing operators to tackle a wider range of tasks with improved efficiency. In this comprehensive guide, we'll explore the intricacies of loader arm extensions, their functions, purposes, types, and applications, providing you with valuable insights into this important piece of equipment.

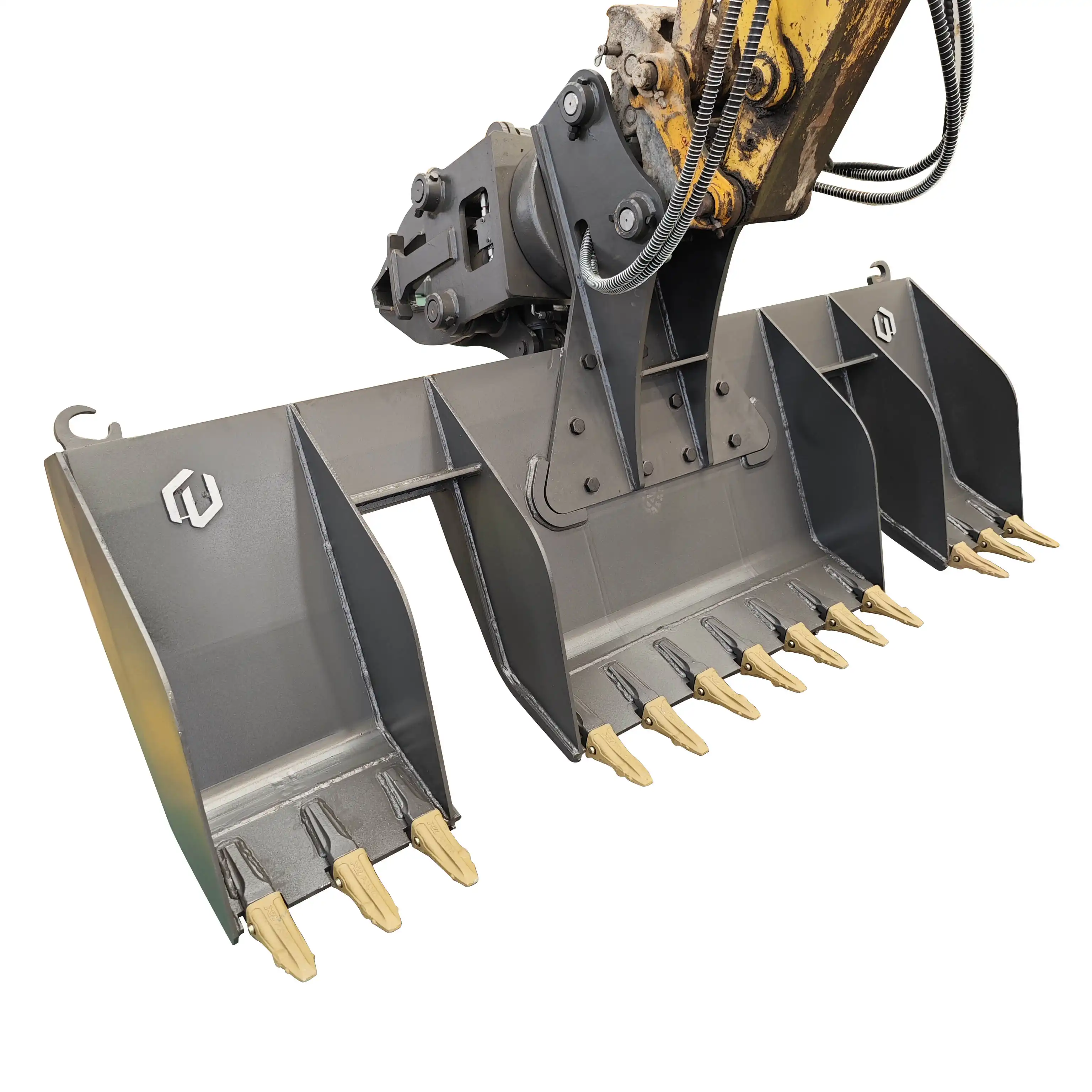

What is a Loader Arm Extension?

A loader arm extension, also known as a boom extension or reach extension, is an attachment designed to increase the length and reach of a loader's arm. This extension effectively allows the loader to access areas that would otherwise be out of reach, enhancing its overall capabilities and versatility. Loader arm extensions are typically made of high-strength steel and are engineered to withstand the rigors of heavy-duty use in construction, mining, and other industrial applications.

These extensions are not permanent modifications to the loader but rather attachments that can be installed and removed as needed. This flexibility allows operators to adapt their equipment to the specific requirements of each job site or task. Loader arm extensions are compatible with various types of loaders, including wheel loaders, skid steer loaders, and compact track loaders, among others.

Its primary purpose is to increase the machine's reach without compromising its stability or lifting capacity. By extending the loader's arm, operators can perform tasks that would otherwise require larger, more expensive equipment or additional machinery on-site. This increased reach translates to improved efficiency, reduced operational costs, and enhanced safety in many applications.

Function and Purpose of Loader Arm Extensions

Loader arm extensions serve several important functions and purposes in various industries and applications. Let's explore some of the key benefits and uses of these versatile attachments:

- Increased Reach: The most obvious function is to increase the reach of the loader. This extended reach allows operators to access areas that would otherwise be inaccessible, such as higher stockpiles, deeper excavations, or across obstacles.

- Enhanced Versatility: By adding a loader arm extension, operators can use their existing equipment for a wider range of tasks. This versatility reduces the need for multiple specialized machines, leading to cost savings and improved efficiency on job sites.

- Improved Safety: they can enhance safety by allowing operators to work at a greater distance from potential hazards. For example, when working on unstable slopes or near excavations, the extended reach keeps the loader and operator at a safer distance.

- Increased Productivity: With the ability to reach higher and farther, they can significantly boost productivity. Operators can load trucks more efficiently, stack materials higher, and complete tasks faster than with standard loader arms.

- Cost-Effective Solution: Instead of purchasing larger, more expensive equipment for occasional high-reach tasks, companies can invest in loader arm extensions. This approach provides a cost-effective solution for increasing the capabilities of existing machinery.

- Adaptability: they can be quickly attached and detached, allowing operators to adapt their equipment to the specific needs of each job or task. This flexibility is particularly valuable on diverse job sites with varying requirements.

The functions and purposes of loader arm extensions make them invaluable tools in construction, mining, agriculture, and various other industries where material handling and loading are essential tasks. By understanding these functions, operators and managers can make informed decisions about incorporating loader arm extensions into their equipment fleet.

Types of Loader Arm Extensions

Loader arm extensions come in various types and configurations to suit different loader models and application requirements. Understanding the different types available can help you choose the most appropriate extension for your specific needs. Here are some common types of loader arm extensions:

- Standard Arm Extensions: These are the most common type of loader arm extensions. They provide a moderate increase in reach and are suitable for a wide range of general applications. Standard arm extensions are versatile and can be used in various industries, including construction, agriculture, and waste management.

- High-Lift Arm Extensions: High-lift arm extensions are designed to provide a significant increase in vertical reach. These extensions are particularly useful for applications that require loading at greater heights, such as filling high-sided trucks or stacking materials to greater heights. High-lift arms typically offer better stability than ultra-high lift arms but may have a slightly reduced lifting capacity compared to standard arms.

- Ultra-High Lift Arm Extensions: As the name suggests, ultra-high lift arm extensions offer the greatest increase in vertical reach. These extensions are specifically designed for applications that require maximum height, such as loading ships, handling high-density materials, or working in specialized industrial settings. Ultra-high lift arms can reach heights of over 6 meters, providing significant advantages in terms of reach. However, they may have reduced lifting capacity and require careful operation to maintain stability.

- Telescopic Arm Extensions: Telescopic arm extensions offer adjustable reach through a series of extendable sections. This design allows operators to adapt the arm length to suit specific task requirements. Telescopic extensions provide excellent versatility but may have lower lifting capacities compared to fixed-length extensions.

- Articulated Arm Extensions: These extensions feature one or more pivot points along the arm, allowing for greater maneuverability and flexibility. Articulated arms are particularly useful in confined spaces or when working around obstacles. They offer excellent reach and versatility but may have more complex hydraulic systems and maintenance requirements.

- Material-Specific Extensions: Some loader arm extensions are designed for specific materials or applications. For example, there are extensions optimized for handling logs in forestry operations, specialized attachments for recycling and waste management, or extensions designed for use in agricultural settings.

When selecting a loader arm extension, it's essential to consider factors such as the loader's base specifications, the intended applications, site conditions, and any specific industry requirements. Each type of extension offers unique advantages and may be better suited for certain tasks or environments.

For example, standard arm extensions are often preferred for their stability and versatility, making them ideal for general construction and quarry operations. On the other hand, ultra-high lift arms excel in specialized applications where maximum reach is critical, such as port operations or certain industrial settings.

It's also important to note that the choice of loader arm extension can impact the machine's overall performance, including its lifting capacity, stability, and maneuverability. Therefore, it's crucial to consult with equipment specialists or manufacturers to ensure that the chosen extension is compatible with your loader and suitable for your specific operational needs.

Applications of Loader Arm Extensions

Loader arm extensions find applications across a wide range of industries and tasks. Their versatility and ability to enhance the capabilities of loaders make them valuable assets in various sectors. Here are some key applications of loader arm extensions:

- Construction: In the construction industry, loader arm extensions are used for a variety of tasks, including:

- Loading and unloading construction materials at greater heights

- Reaching over obstacles or barriers on construction sites

- Placing materials in hard-to-reach areas of buildings under construction

- Assisting in demolition work by providing extended reach for attachments

- Mining and Quarrying: Loader arm extensions are crucial in mining and quarrying operations for:

- Loading high-sided haul trucks more efficiently

- Reaching deeper into quarry faces to extract materials

- Stacking and managing stockpiles of extracted materials

- Assisting in the maintenance of large mining equipment

These applications demonstrate the versatility and importance of loader arm extensions across various industries. By extending the reach and capabilities of loaders, these attachments enable operators to tackle a wide range of tasks more efficiently and safely.

It's worth noting that the specific application of loader arm extensions can vary depending on the type of extension used. For instance, ultra-high lift arms may be preferred in port operations or specialized industrial settings where maximum reach is critical. On the other hand, standard or high-lift arms might be more suitable for general construction or quarry operations where a balance between reach and stability is essential.

Tiannuo Machinery Loader Arm Extensions

Loader arm extensions are invaluable attachments that significantly enhance the capabilities of loaders across various industries. By increasing reach, improving versatility, and boosting productivity, these extensions have become essential tools in construction, mining, agriculture, and many other sectors. Understanding the different types of loader arm extensions and their applications can help operators and managers make informed decisions about equipment selection and utilization.

At Tiannuo Machinery, we offer a range of loader arm extensions to suit different needs and applications. Our product line includes standard arms, which are preferred for their stability and versatility, especially in quarry operations. We also provide high-lift and ultra-high lift arms, with the latter designed specifically for handling high-density materials and elevated loading tasks. Our ultra-high lift arms can reach over 6 meters, offering significant advantages in terms of reach and capability.

If you're in the market for a loader arm extension and seeking a reliable manufacturer, we invite you to explore the options available at Tiannuo Machinery. Our team of experts is ready to assist you in selecting the right extension for your specific needs. For more information or to discuss your requirements, please don't hesitate to contact us. You can reach our manager at arm@stnd-machinery.com, or get in touch with our team members at rich@stnd-machinery.com and tn@stnd-machinery.com. Let us help you extend your loader's capabilities and improve your operational efficiency today!

References:

- Construction Equipment Guide. (2021). "The Benefits of Loader Arm Extensions in Construction."

- Mining Technology. (2020). "Applications of Loader Arm Extensions in Mining Operations."

- Agricultural Engineering Today. (2022). "Improving Farm Efficiency with Loader Arm Extensions."

- Waste Management World. (2021). "The Role of Loader Arm Extensions in Modern Recycling Facilities."

- Port Technology International. (2022). "Enhancing Port Operations with Advanced Loader Arm Extensions."