What are the key technical parameters of railway sleeper changers?

Railway sleeper changers are essential machines in the maintenance and renovation of railway tracks. These specialized pieces of equipment play a crucial role in efficiently replacing worn-out or damaged sleepers, ensuring the safety and reliability of rail networks.

Load Capacity and Lifting Force: Essential Performance Metrics

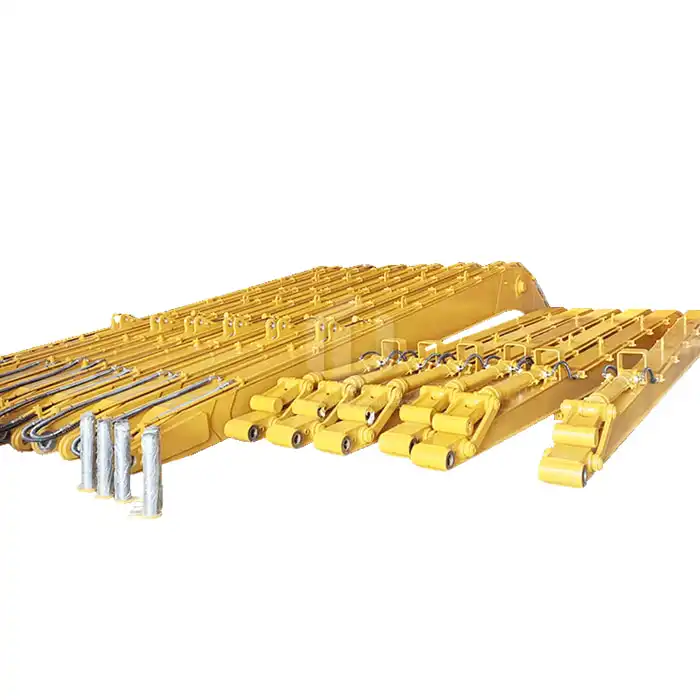

One of the most crucial aspects of a railway sleeper changer is its load capacity and lifting force. These parameters determine the machine's ability to handle and replace sleepers effectively. The load capacity refers to the maximum weight the sleeper changer can safely lift and maneuver, while the lifting force indicates the power exerted by the machine's hydraulic system to raise and position sleepers.

Typically, railway sleeper changers have a load capacity ranging from 5 to 15 tons, depending on the model and intended application. This capacity allows them to handle various types of sleepers, including concrete, wooden, and composite materials. The lifting force of these machines usually falls between 30 to 60 kN (kilonewtons), providing sufficient power to extract old sleepers and insert new ones with precision.

It's important to note that the maximum excavating force of a sleeper changer, which can reach up to 50 kN in some models, plays a significant role in its overall performance. This force enables the machine to effectively dig out old sleepers and prepare the track bed for new installations. The combination of load capacity, lifting force, and excavating force ensures that the sleeper changer can handle a wide range of maintenance tasks efficiently.

When selecting a railway sleeper changer, maintenance teams should consider the specific requirements of their railway network, including the types of sleepers used and the frequency of replacement operations. Choosing a machine with appropriate load capacity and lifting force ensures optimal performance and longevity of the equipment.

Hydraulic System and Control Mechanism: Key Specifications

The hydraulic system and control mechanism are the heart of a railway sleeper changer, determining its precision, efficiency, and ease of operation. Modern sleeper changers employ advanced hydraulic systems that provide smooth and controlled movements, essential for delicate operations in track maintenance.

One of the key specifications in this category is the rotation angle of the sleeper changer's arm. Many advanced models offer a 360-degree rotation capability, allowing operators to position the machine precisely and work from various angles. This feature significantly enhances the versatility of the sleeper changer, enabling it to operate effectively in confined spaces and challenging track layouts.

The control mechanism of a railway sleeper changer typically includes a combination of joysticks, buttons, and digital interfaces. These controls allow operators to manipulate the machine with high precision, adjusting parameters such as lifting height, arm extension, and grip strength. Advanced models may incorporate computerized systems that enable pre-programmed movements and automate certain aspects of the sleeper changing process, improving efficiency and reducing operator fatigue.

Another critical specification is the sleeper clip opening range. For instance, some models can accommodate clip openings of up to 650mm, allowing them to work with a wide variety of sleeper designs and fastening systems. This adaptability is crucial for maintenance teams working on diverse railway networks with different track configurations.

The hydraulic system's power and efficiency also influence the machine's overall performance. Factors such as pump capacity, operating pressure, and flow rate contribute to the sleeper changer's ability to perform tasks quickly and smoothly. When evaluating different models, it's essential to consider these hydraulic specifications in relation to the specific requirements of the intended maintenance operations.

Adaptability and Compatibility with Different Railway Tracks

The versatility of a railway sleeper changer is a critical factor in its overall utility and value. Modern sleeper changers are designed to be adaptable to various track configurations and operating conditions, making them invaluable assets for railway maintenance teams.

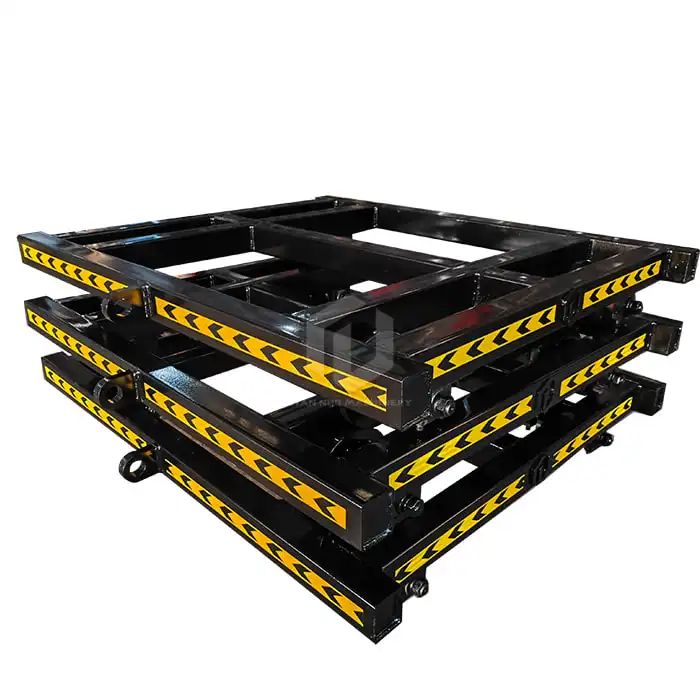

One of the key aspects of adaptability is the machine's ability to operate on different track gauges. For example, some railway sleeper changers are designed with a track gauge of 1610mm, which is compatible with standard gauge railways used in many countries. However, advanced models may offer adjustable track gauge settings, allowing them to work on both standard and broad gauge tracks. This flexibility is particularly important for railway networks that incorporate multiple gauge standards or for maintenance companies that service diverse railway systems.

The railway operation walking mode is another crucial feature that enhances the adaptability of sleeper changers. Many modern machines offer a power wheel convertible freewheel mode, allowing them to transition seamlessly between self-propelled operation on tracks and free-rolling movement when being transported or repositioned. This dual-mode capability significantly improves the machine's mobility and reduces setup time between work sites.

The maximum digging radius is an important specification that determines the sleeper changer's reach and working area. With some models offering a digging radius of up to 6340mm, operators can efficiently replace sleepers without frequently repositioning the machine. This extended reach is particularly beneficial when working on curved sections of track or in areas with limited access.

Another aspect of adaptability is the sleeper changer's ability to operate on various surfaces. High-performance models are designed to work effectively on both normal road surfaces and railway lines. This versatility allows the machine to be easily transported to different work sites and navigate through rail yards and maintenance facilities.

The standard bucket capacity, typically around 0.3m³, is an important consideration for tasks that involve excavation or material handling. This feature allows the sleeper changer to perform additional maintenance tasks, such as ballast regulation or debris removal, further enhancing its utility in track maintenance operations.

Railway Sleeper Changer Quotation

Understanding the key technical parameters of sleeper changers is crucial for making informed decisions in railway maintenance and infrastructure development. These sophisticated machines, with their advanced hydraulic systems, adaptable designs, and powerful lifting capabilities, play a vital role in ensuring the safety and efficiency of rail networks worldwide.

If you are choosing your railway sleeper changer manufacturer, welcome to contact our team:

- Manager's email: arm@stnd-machinery.com

- Team emails: rich@stnd-machinery.com and tn@stnd-machinery.com

References

- Railway Track Engineering by J.S. Mundrey (2017)

- Modern Railway Track by Coenraad Esveld (2001)

- Railway Maintenance Equipment by Frank J. Ackerman (1989)

- International Union of Railways (UIC) Technical Report on Track Maintenance Machines (2018)